Low-temperature environmentally-friendly preparation method of nitrogen edge doped graphene

A graphene and edge technology, applied in the field of low-temperature environmental protection preparation, can solve the problems of difficult adjustment of experimental process parameters, influence of electronic conductivity, complex experimental conditions and mechanism, etc., and achieve the effect of improving electrochemical catalytic ability and high structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) First, conduct solid-phase ball milling of graphite powder and chitosan to obtain a powder: mix graphite powder and chitosan solids in a mass ratio of 1:20 and add them to the ball mill tank. Continuous ball milling at a speed of 400r / min for 12 hours.

[0025] (2) Then mix the powder with water, centrifuge to remove excess graphite powder and chitosan: transfer the product to a sample bottle with deionized water, and then centrifuge at a speed of 4000r / min to remove unreacted chitosan and chitosan graphite powder.

[0026] (3) Finally, dialyze the solution obtained in step (2) with water until the solution is neutral: put the supernatant into a dialysis bag and replace deionized water repeatedly until the solution is neutral, and nitrogen-doped graphite with good dispersibility is obtained alkene.

Embodiment 2

[0028] (1) First, conduct solid-phase ball milling of graphite powder and chitosan to obtain a powder: mix graphite powder and chitosan solids in a mass ratio of 1:20 and add them to the ball mill tank. Continuous ball milling at a speed of 600r / min for 8 hours.

[0029] (2) Then mix the powder with water, centrifuge to remove excess graphite powder and chitosan: transfer the product to a sample bottle with deionized water, and then centrifuge at a speed of 3000r / min to remove unreacted chitosan and chitosan graphite powder.

[0030] (3) Finally, dialyze the solution obtained in step (2) with water until the solution is neutral: put the supernatant into a dialysis bag and replace deionized water repeatedly until the solution is neutral, and nitrogen-doped graphite with good dispersibility is obtained alkene.

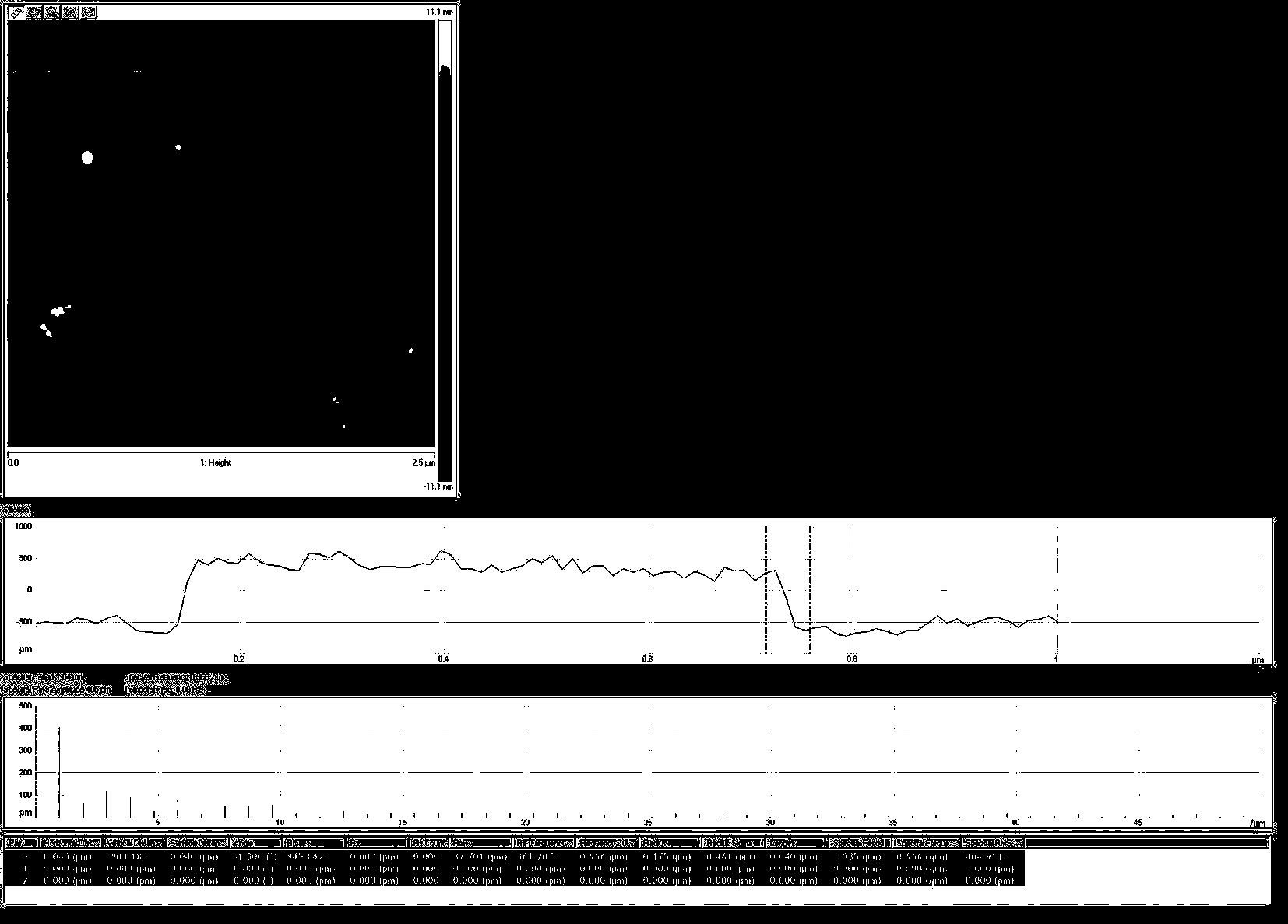

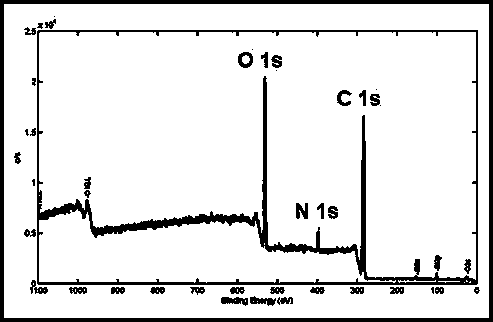

[0031] Analyzing the properties of the products of Example 1 and Example 2: Observing the morphology of the product obtained by SEM, determining its thickness by AFM, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com