Polyurea lubricating grease and preparation method thereof

A polyurea grease and urea-based technology, applied in the field of polyurea grease, can solve the problems of no extreme pressure, large impact of bearing noise, large particle size, etc., to reduce friction, prolong service life, and reduce friction factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

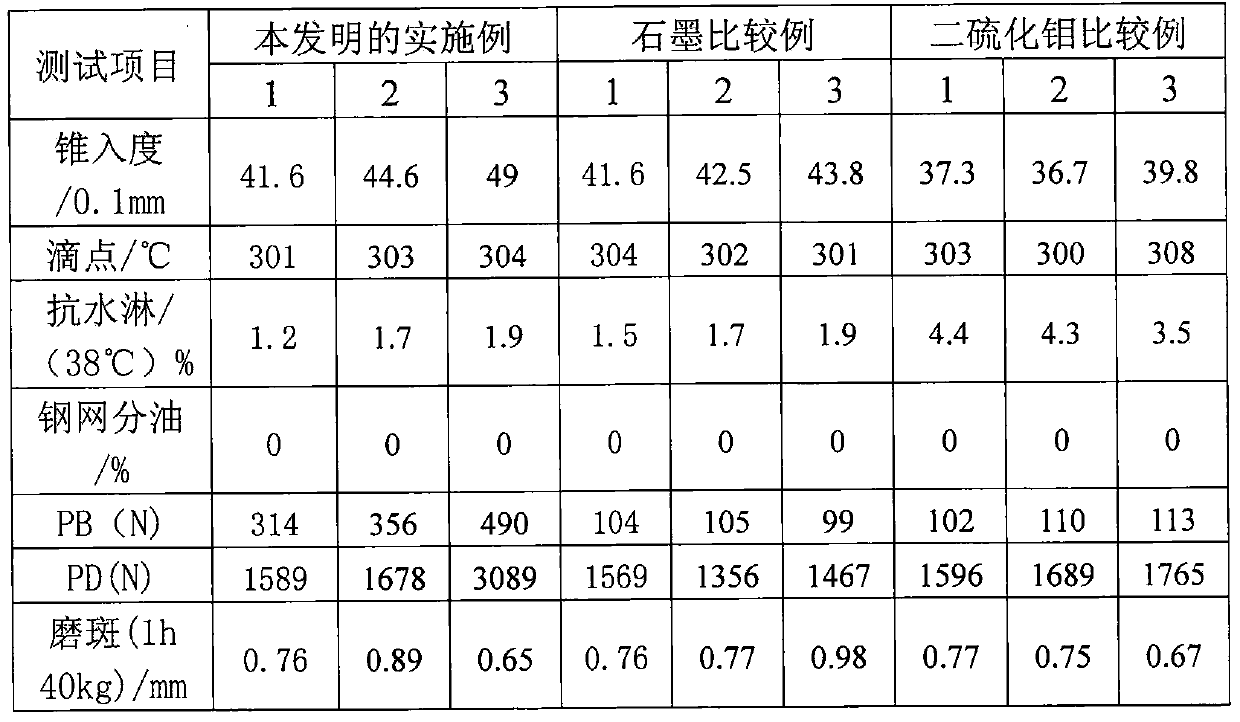

Examples

Embodiment 1

[0019] First, the 100°C viscosity of 12mm, which accounts for 70% of the weight of polyurea grease, is 2 Put two-thirds of 500SN mineral oil per second and urea-based thickener accounting for 20% of the weight of polyurea grease into a container with a stirring container and a heater and heat it to 70°C, and turn it on when it is heated to 70°C The stirrer was stirred at a speed of 300rpm for 25min. After the stirring was completed, the temperature was raised to 140°C, and the temperature was kept for 60min. After the heat preservation was completed, the temperature was raised to 170°C again and then stirred. Then after the stirring is finished, heat up and stir further, the temperature of the heat rise is 200°C, the stirring speed is 200rpm, the stirring time is 25min, and the remaining (remaining) 1 / 3 is added during the stirring process The aforementioned 500SN mineral oil, and the remaining 1 / 3 of the 500SN mineral oil is added within 3min, then under stirring and in a cir...

Embodiment 2

[0021] First, the viscosity of 5mm at 100°C, which accounts for 54% of the weight of polyurea grease, is 2 / s olefin oil with a viscosity of 10mm at 100°C2 2 / 3 of the 100SN mineral oil mixed at a weight ratio of 1:1 and the urea-based thickener accounting for 30% of the weight of polyurea grease are put into a container with a stirring container and a heater and heated to 75°C When heating to 75°C, turn on the stirrer and stir at a speed of 100rpm for 35min. After the stirring is completed, the temperature is raised to 120°C, and the heat preservation is carried out for 120min. Then the time of stirring is 50min, and then heat up and then stir after stirring finishes, then the temperature of further heating is 190 ℃, and then the speed of stirring is 300rpm, and then the time of stirring is 20min, add remaining ( The remaining one-third of the mixture of the aforementioned olefin oil and mineral oil, and the remaining one-third of the mixture of olefin oil and mineral oil was ...

Embodiment 3

[0023] First, the 100°C viscosity of 30mm at 100°C, which accounts for 89% of the weight of polyurea grease 2 Two-thirds of the vegetable oil per s and the urea-based thickener accounting for 10% of the weight of polyurea grease are put into a container with a stirring container and a heater and heated to 80°C. When heated to 80°C, turn on the agitator and Stir at a speed of 200rpm for 30min, heat up to 130°C after stirring, and keep warm for 100min. Then heat up and then stir, the temperature of this heat up is 195°C, the speed of stirring is 100rpm, the time of stirring is 30min, and the remaining (remaining) 1 / 3 of the aforementioned vegetable oil is added in the process of stirring , and the remaining one-third of the vegetable oil was added within 0.5min, then cooled to 105 ° C, and then added fluorinated graphite with a particle size of 50 μm accounting for 1% by weight of polyurea grease, and stirred again, the The speed of re-stirring is 200rpm, and the time of re-sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com