Light-emitting diode and preparation method of buffer layer thereof

A technology for light-emitting diodes and buffer layers, which can be used in coatings, metal material coating processes, semiconductor/solid-state device manufacturing, etc., and can solve problems such as poor lattice matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

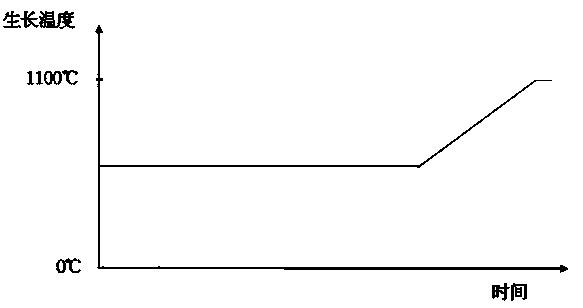

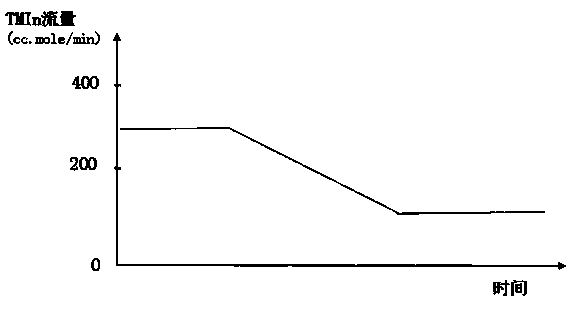

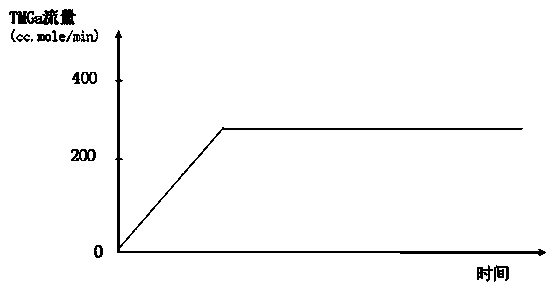

[0020] Grow Indium with a gradient of indium and gallium composition with a thickness of 400? on a sapphire substrate x Ga 1-x N buffer layer, before epitaxial growth, adjust the temperature to 550℃, pressure to 400torr, use nitrogen as the carrier gas, ammonia as the reaction gas, adjust the TMIn flow rate to 300cc.mole / min, and maintain the reaction conditions such as reaction temperature and pressure No change, control the flow rate of TMIn unchanged, start to pass into TMGa, and its flow rate will increase from 0cc.mole / min at a uniform rate. When the buffer layer grows to 1 / 4 of the total thickness of the buffer layer, the flow rate of TMGa reaches 300 cc.mole / min, the flow rate of TMIn begins to decrease at a uniform rate. When the buffer layer grows to 3 / 4 of its total thickness, the flow rate of TMIn decreases to 1 / 4 of the original flow rate. During the process, the flow rate of TMGa remains at 300 cc.mole / min. To maintain the flow rate of TMIn and TMGa at this time, i...

Embodiment 2

[0022] Growing on a sapphire substrate with a thickness of 250? Indium and gallium composition gradient change In x Ga 1-x N buffer layer, before epitaxial growth, adjust the temperature to 580℃, pressure to 350torr, use nitrogen as the carrier gas, ammonia as the reaction gas, adjust the TMIn flow rate to 310cc.mole / min, and maintain the reaction conditions such as reaction temperature and pressure No change, control the flow rate of TMIn unchanged, start to pass TMGa, its flow rate increases from 0cc.mole / min at a uniform rate, when the buffer layer grows to 1 / 4 of the total thickness of the buffer layer, the flow rate of TMGa reaches 295 cc.mole / min. At this time, the flow rate of TMIn decreases at a uniform rate. When the buffer layer grows to 3 / 4 of its total thickness, the flow rate of TMIn drops to 1 / 4 of the original flow rate. During the process, the flow rate of TMGa remains at 295 cc.mole / min. Maintain the flow rate of TMIn and TMGa at this time. During the last 1 / 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com