Water-quenched slag silicate series coagulants and preparation method thereof

A water-quenched slag and silicic acid-based technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as insufficient utilization, imperfect preparation technology, and complexity, and achieve the effect of removing turbidity and COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

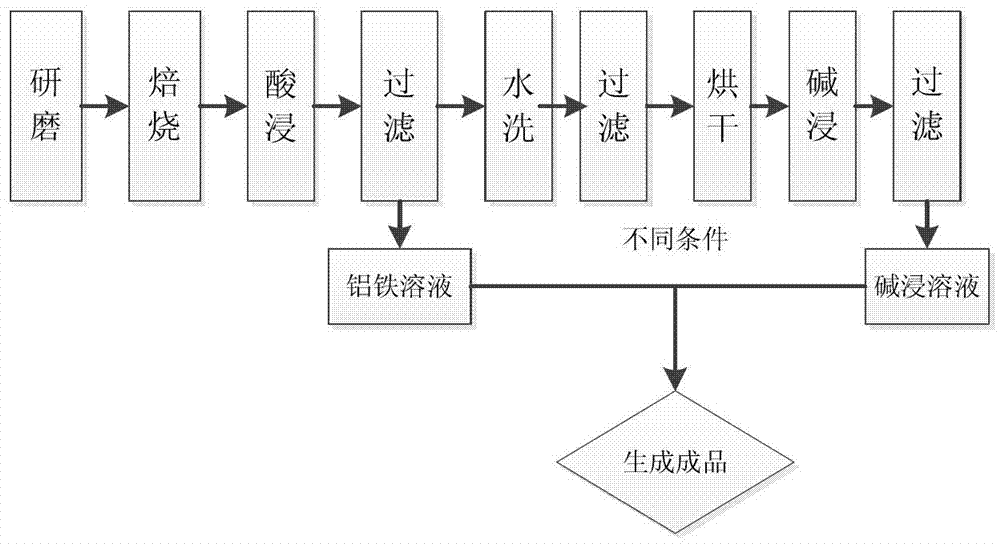

Method used

Image

Examples

Embodiment 1

[0027] Prepare the acid leaching solution first, and then prepare the alkaline leaching solution.

[0028] 1) Weigh 5g of water-quenched slag and 1.5g of anhydrous sodium carbonate at room temperature, mix them evenly in a crucible, place them in a muffle furnace and heat them up to 900°C or 1000°C with the furnace, keep them warm for 2 hours, take them out and cool them down to room temperature. After raising the temperature of the water bath to 90-100°C, crush the mixed material and pour it into a beaker, add 100-125mL H 2 SO 4 The solution was reacted at a constant temperature for 1 hour; after acid leaching, the mixture was filtered with a suction filter, and the filtrate was left standing for later use;

[0029] 2) Add the filter residue after suction filtration and 150mL tap water into a large beaker, stir rapidly on a magnetic heating stirrer for 1min, and take out the suction filter after 15 minutes at a constant temperature of 100°C; put the filter residue of suction...

Embodiment 2

[0033] According to the steps 1), 2), and 3) in Example 1, acid dipping solution and alkali dipping solution were prepared. In a 60°C water bath, 10 mL of alkali dipping solution was added to a 125 mL Erlenmeyer flask, and 40 mL of acid dipping solution was slowly Pour it into the alkali immersion solution and polymerize for 30 minutes to obtain finished product No. 2.

Embodiment 3

[0035] According to steps 1), 2) and 3) in Example 1, acid dipping solution and alkali dipping solution were prepared, and 10 mL of alkaline dipping solution and 40 mL of acid dipping solution were mixed in a conical flask at room temperature, and then added to the conical flask The NaOH solution with a mass concentration of 8mol / L makes the pH value of the solution at 7 to generate finished product No. 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com