Method for manufacturing semiconductor device patterned structure

A manufacturing method and patterning technology, applied in semiconductor/solid-state device manufacturing, photoengraving process of patterned surface, originals for opto-mechanical processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those who are familiar with the technical field of the present invention to further understand the present invention, the preferred embodiments of the present invention are listed below, together with the accompanying drawings, to describe in detail the composition of the present invention and the desired effects .

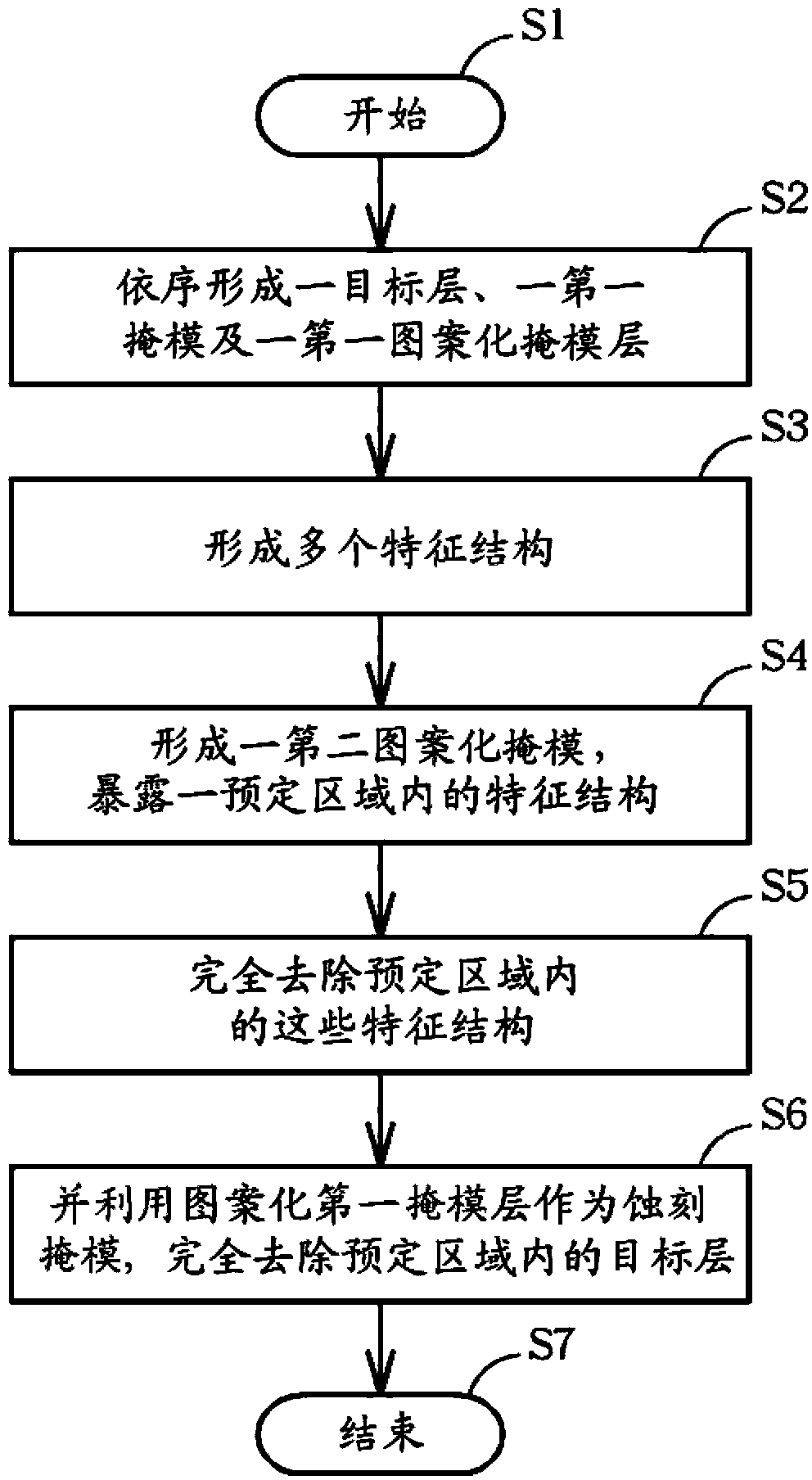

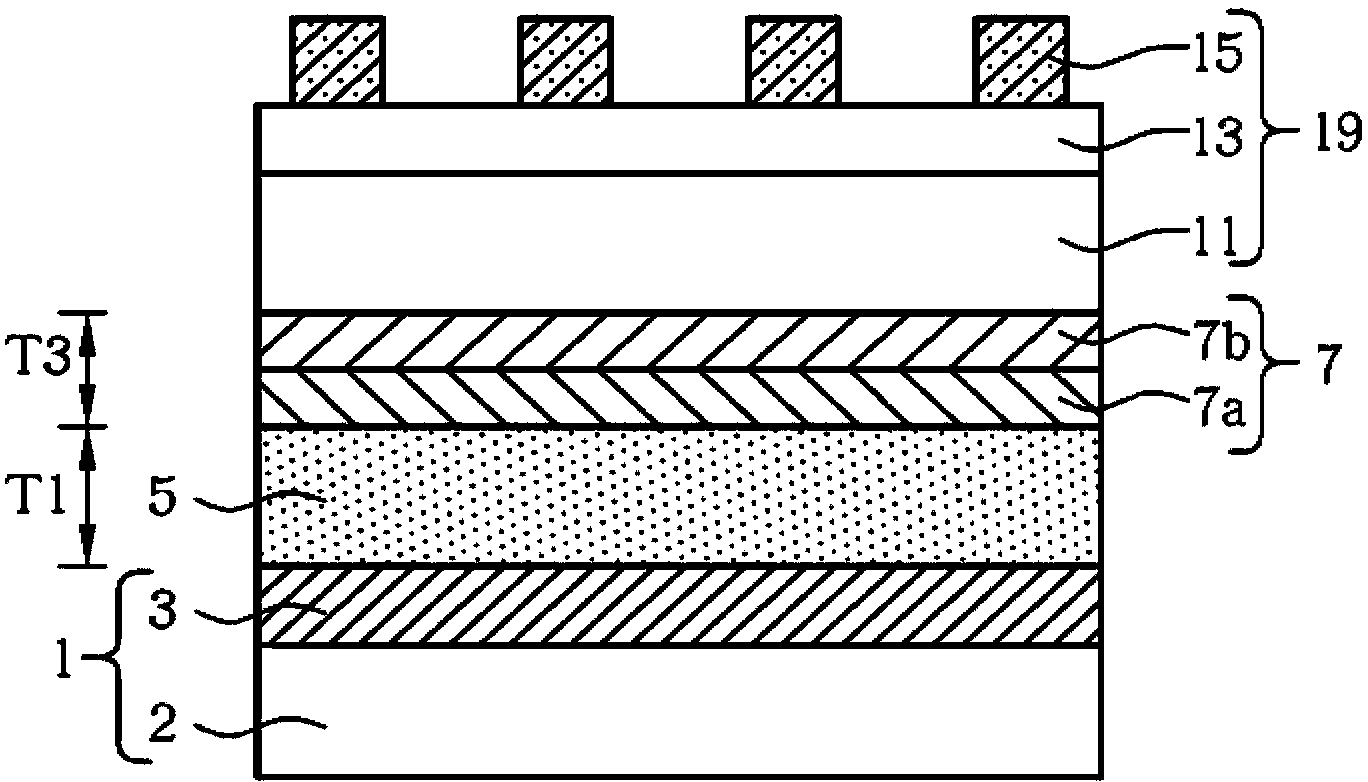

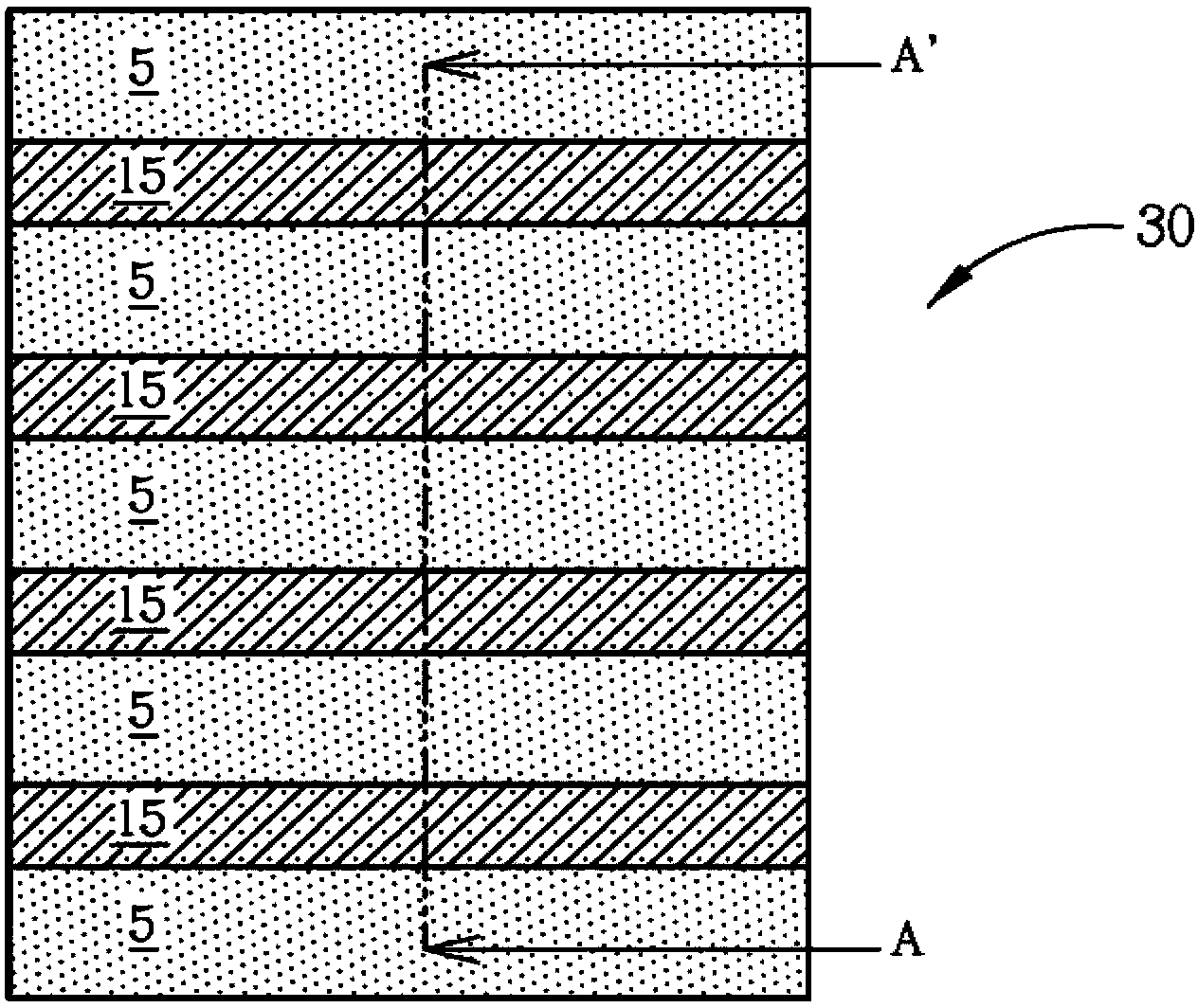

[0040] see figure 1 , figure 1 Shown is a flowchart of a method for fabricating a patterned structure of a semiconductor device according to a preferred embodiment of the double patterning technique (DPT) of the present invention. The process of the present invention is roughly as follows: first, starting with step S1, using step S2 to sequentially form at least a target layer, a first mask layer and a first patterned mask layer on a substrate. Then proceed to step S3 , forming a plurality of feature structures on the substrate by a first etching process, wherein each feature structure includes a patterned first mask and a patterned tar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com