Electrophoretic display and manufacturing method thereof

An electrophoretic display, electrophoretic display technology, applied in the direction of instruments, nonlinear optics, optics, etc., to achieve the effect of avoiding damage, reducing damage, and improving the yield of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

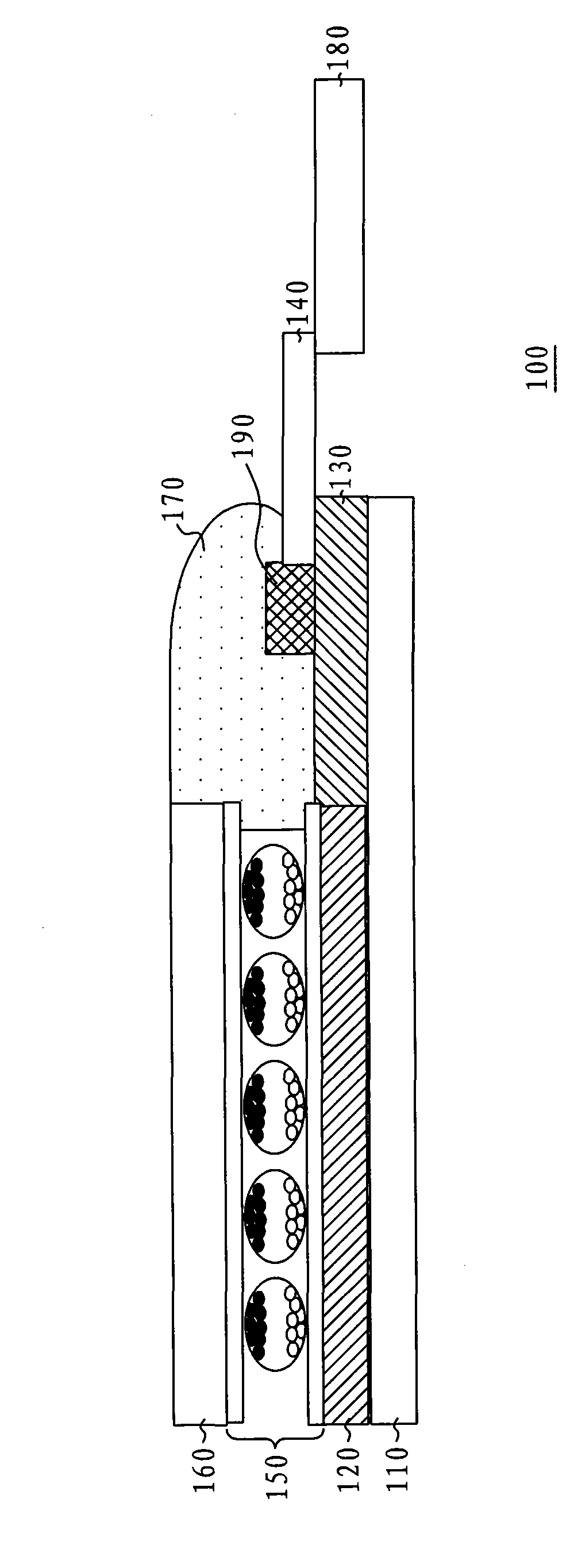

Image

Examples

Embodiment Construction

[0053] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, method, Steps, features and effects thereof are described in detail below.

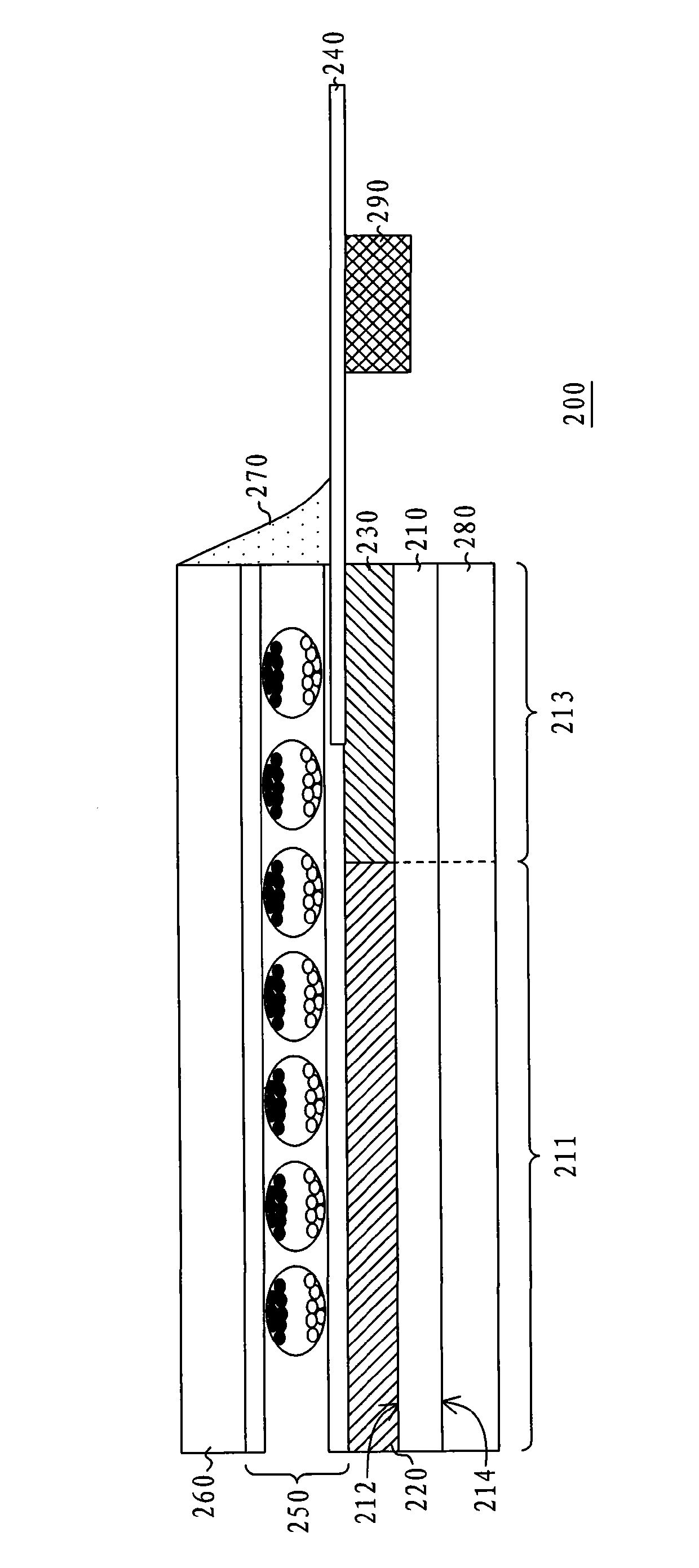

[0054] figure 2 It is a partial cross-sectional schematic diagram of an electrophoretic display in an embodiment of the present invention. Please refer to figure 2 As shown, the electrophoretic display 200 includes a first substrate 210 , an active element array 220 , a driving circuit 230 , a conductive flexible plate 240 , an electrophoretic display layer 250 , a second substrate 260 and a sealant 270 . Wherein, the first substrate 210 has a first surface 212 , and the first surface 212 has a display area 211 and a circuit area 213 . The first substrate 210 of this embodiment may be a flexible substrate made of plastic materials. Specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com