Support-free perforated metal film preparation method

A porous metal and support type technology, applied in the field of porous material processing, can solve the problems of high cost, reported, complicated process, etc., and achieve the effect of solving difficult forming and difficult control, solving stress release cracking, and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

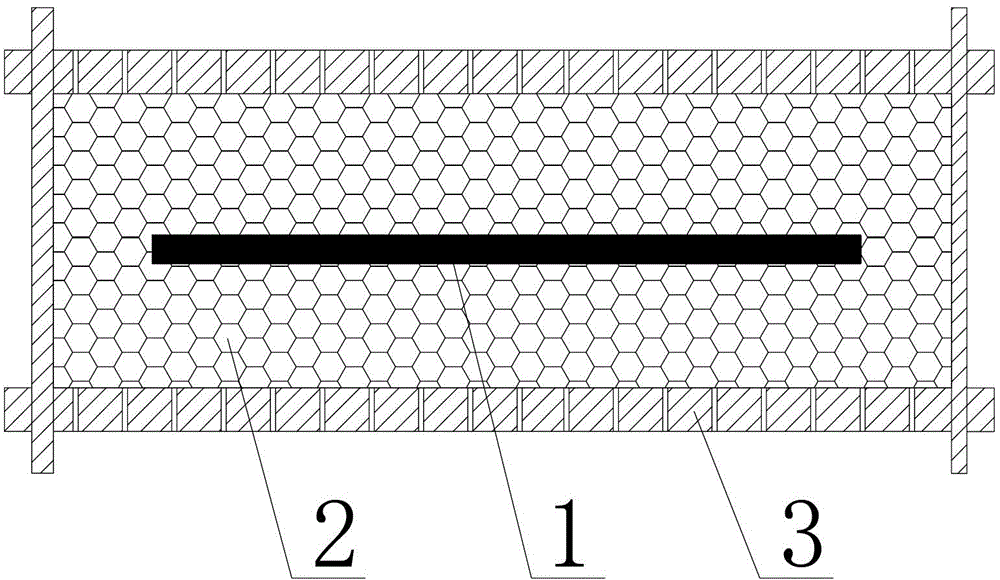

[0035] combine figure 1 , the preparation method of the present embodiment unsupported porous metal membrane comprises the following steps:

[0036] Step 1. Put metal powder with an average particle size of 0.5 μm and 3% polyvinyl alcohol aqueous solution in a mass ratio of 1:3 into a ball mill and mix them evenly to obtain a slurry; the metal powder is preferably stainless steel powder , titanium powder, nickel powder, titanium alloy powder, nickel alloy powder or FeAl alloy powder, the metal powder that present embodiment adopts is 316L stainless steel powder;

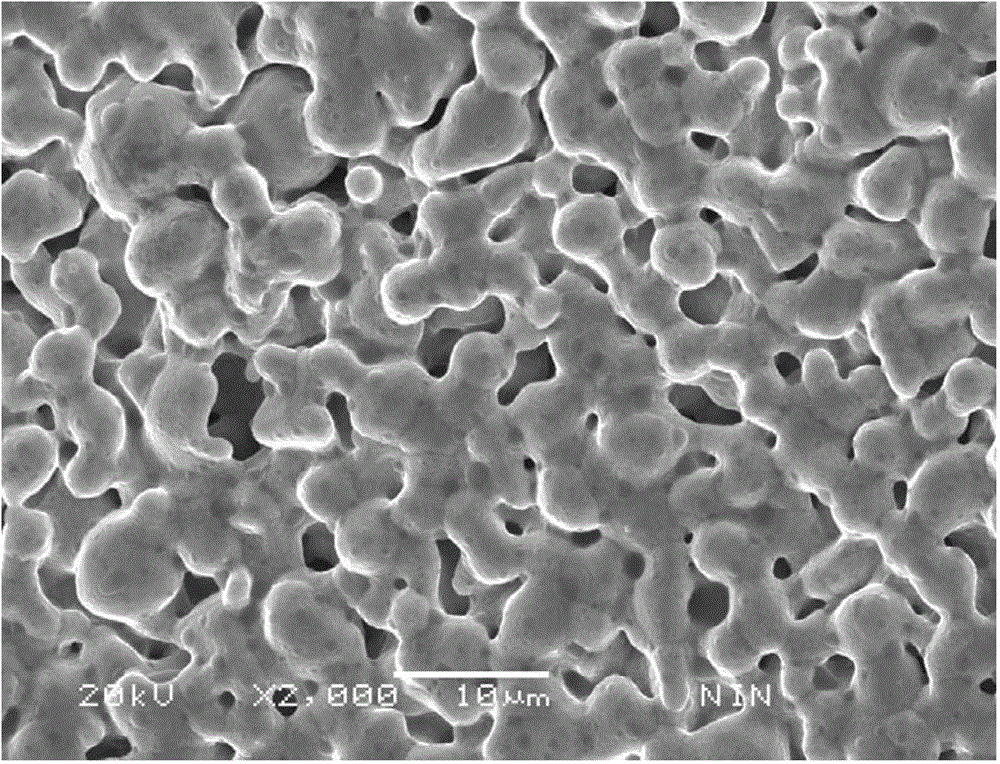

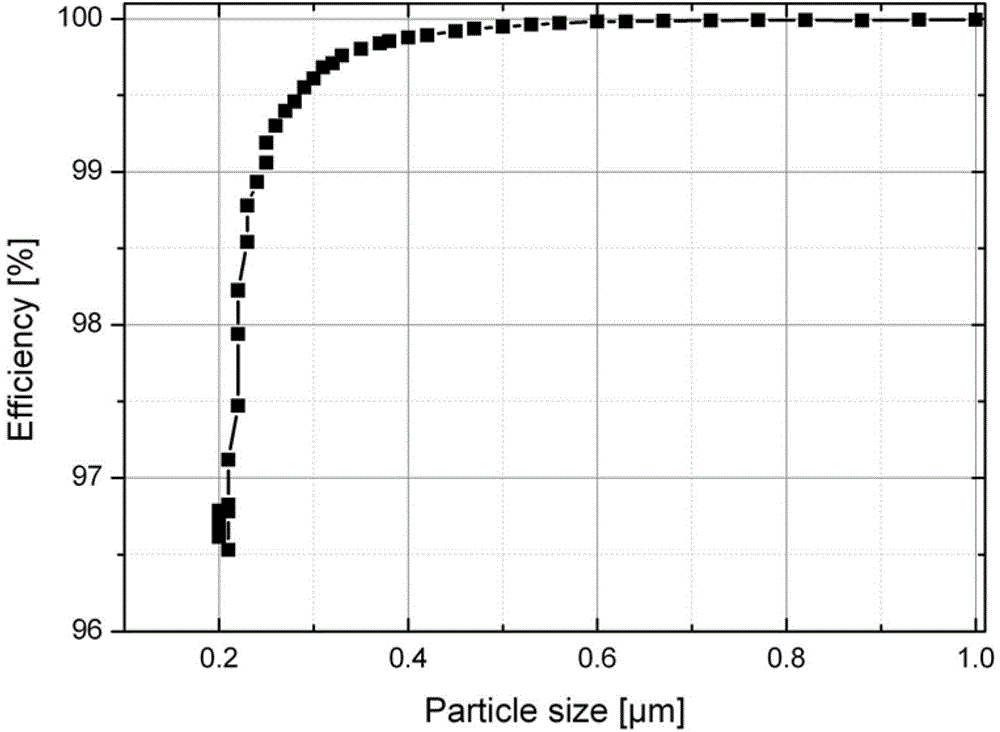

[0037]Step 2. Use the brushing method to evenly coat the slurry described in step 1 on the surface of the substrate, and then place the substrate coated with the slurry in a drying oven to dry at a drying temperature of 60°C and a drying time of 2 hours. Cool naturally Finally, a metal film layer is formed on the surface of the substrate, and then the metal film layer is peeled off from the substrate to obtain an un...

Embodiment 2

[0045] combine figure 1 , the preparation method of the present embodiment unsupported porous metal membrane comprises the following steps:

[0046] Step 1. Put metal powder with an average particle size of 0.5 μm and 3% polyvinyl alcohol aqueous solution in a mass ratio of 1:3 into a ball mill and mix them evenly to obtain a slurry; the metal powder is preferably stainless steel powder , titanium powder, nickel powder, titanium alloy powder, nickel alloy powder or FeAl alloy powder, the metal powder that present embodiment adopts is 304L stainless steel powder;

[0047] Step 2. Apply the slurry described in step 1 evenly on the surface of the substrate by casting method, and then place the substrate coated with the slurry in a drying oven to dry. The drying temperature is 70°C, the drying time is 3 hours, and it is naturally cooled. Finally, a metal film layer is formed on the surface of the substrate, and then the metal film layer is peeled off from the substrate to obtain ...

Embodiment 3

[0055] combine figure 1 , the preparation method of the present embodiment unsupported porous metal membrane comprises the following steps:

[0056] Step 1, adding metal powder with an average particle size of 12 μm and 2% polyvinyl alcohol aqueous solution in a mass ratio of 1:2 into a ball mill and ball milling to obtain a slurry; the metal powder is preferably stainless steel powder, Titanium powder, nickel powder, titanium alloy powder, nickel alloy powder or FeAl alloy powder, the metal powder that present embodiment adopts is titanium powder;

[0057] Step 2. Use the brushing method to evenly coat the slurry described in step 1 on the surface of the substrate, and then place the substrate coated with the slurry in a drying oven to dry at a drying temperature of 50°C and a drying time of 2 hours. Cool naturally Finally, a metal film layer is formed on the surface of the substrate, and then the metal film layer is peeled off from the substrate to obtain an unsupported met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com