Micropore thin film micro-fluidic chip as well as preparation method and application thereof

A technology of microfluidic chips and microporous films, applied in chemical instruments and methods, containers used in laboratories, and analysis through chemical reactions of materials, etc., can solve complex technology participation in production, increase production costs, and operators Harm and other issues, to achieve good environmental compatibility, low cost, and less harmful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, the making of nylon microporous film microfluidic chip

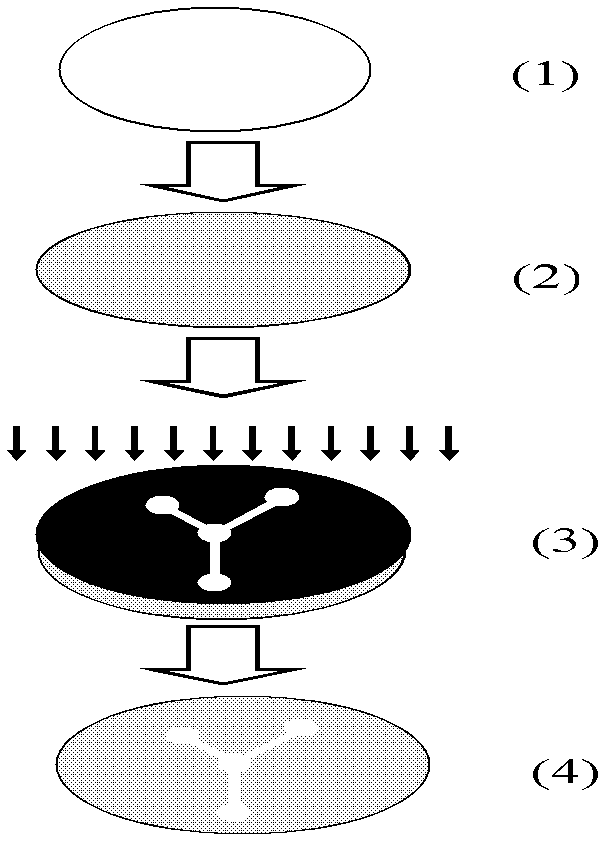

[0028] 1) if figure 1 Shown in (1), the nylon microporous film 1 that thickness is 100 μ m, porosity 70%, aperture is 0.45 μ m is soaked in the photoresist of positive-type ultraviolet photoresist 3 minutes, makes photoresist fully contact with film microporous film The holes are in contact with each other and filled, take it out and let it stand for 10 minutes, so that the excess photoresist on the film will drop naturally and be initially cured; The resist cures to form a hard photoresist film, such as figure 1 (2) shown.

[0029] 3) Use high-resolution printing technology to print channel graphics on black and white film with a printing resolution of 3657dpi; put a black mask close to the photoresist film for UV exposure, and the exposure ends after 10 minutes, using a mass percent concentration of 0.7 % sodium hydroxide aqueous solution washes off the UV positive photoresist after exposure to ...

Embodiment 2

[0033] Embodiment 2, the making of polypropylene microporous film microfluidic chip

[0034] 1) if figure 1 As shown in (1), the polypropylene microporous film 1 with a thickness of 150 μm, a porosity of 80%, and a pore diameter of 0.5 μm is soaked in the positive-type UV photoresist photoresist for 2 minutes, so that the photoresist is fully in contact with the film. Contact the micropores and fill them, take them out and let them stand for 15 minutes to allow the excess photoresist on the film to drip naturally and preliminarily cure; then place the incompletely cured film on an electric heating plate at 75°C and bake for 20 minutes. The photoresist cures to form a hard photoresist film, such as figure 1 (2) shown.

[0035] 3) Use high-resolution printing technology to print channel graphics on black and white film with a printing resolution of 3657dpi; put the black mask close to the photoresist film for UV exposure, and the exposure ends after 8 minutes, with a mass perc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com