Spring type nanometer generator and self-driven dynamometer

A nano-generator and spring-type technology, which is applied in the direction of generator/motor, the measurement of the force of the piezoelectric device, the piezoelectric effect/electrostrictive or magnetostrictive motor, etc., which can solve the inconvenience of normal operation of the components , Low mechanical strength, application limitations, etc., to achieve the effect of miniaturization, expanded application range, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

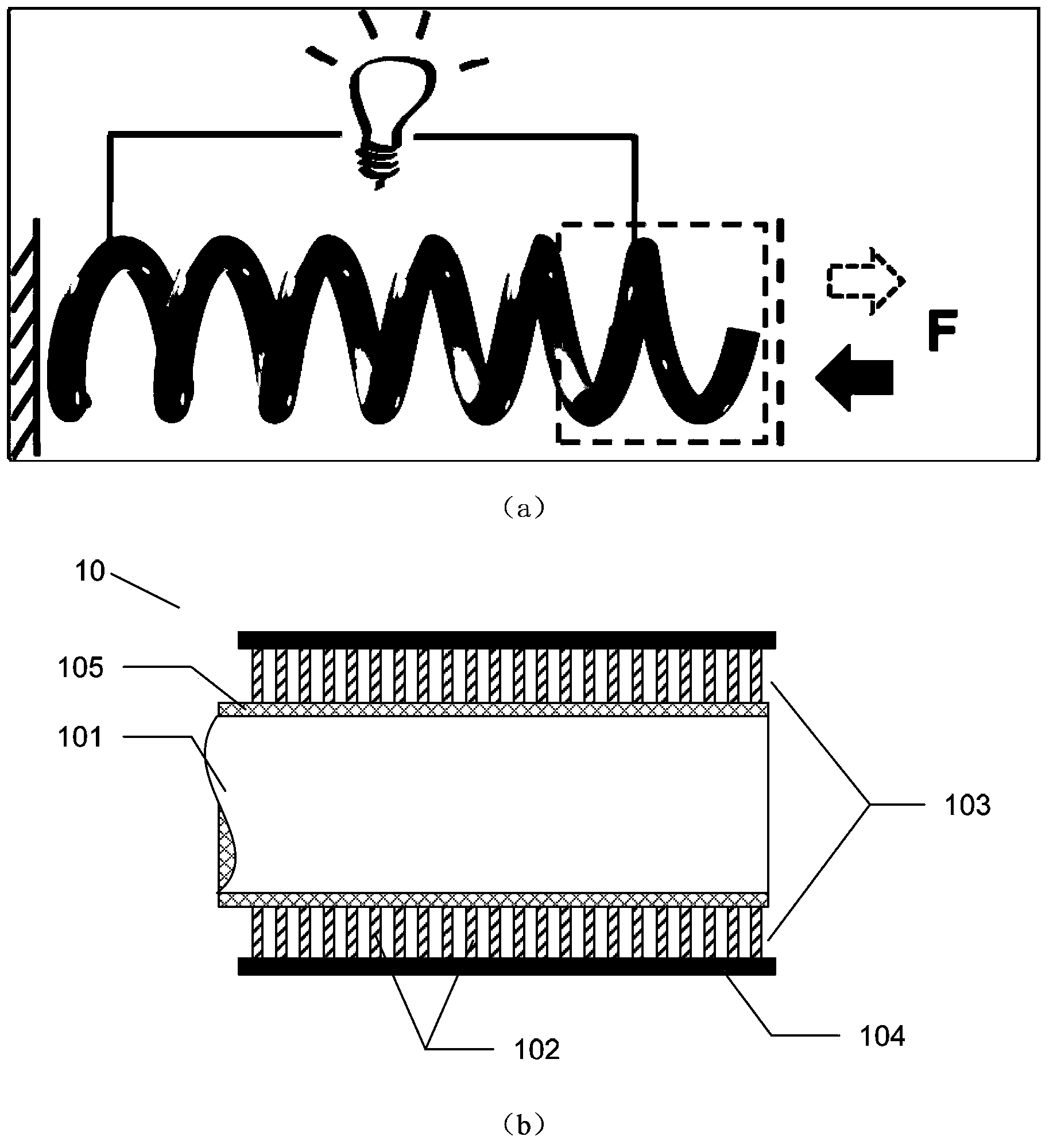

[0082] Embodiment 1: spring type nanogenerator

[0083] A copper spring with a length of 3.5 inches and a spring wire diameter of 0.028 inches is used as the substrate, and an array of closely arranged CdS nanorods is formed on its surface by in-situ preparation to form a piezoelectric layer. The gap of the rod array is filled with insulating material polyimide, and after cooling and solidification, an Au electrode layer is formed by sputtering on the outside of the piezoelectric layer. The spring-type nano generator of the present invention can be formed by connecting the Au electrode layer and the stainless steel wire with an external circuit.

Embodiment 2

[0084] Embodiment 2: the preparation method of spring type nanogenerator

[0085] Although the in-situ preparation of nano piezoelectric materials is a conventional method in the art, a typical method for preparing nanogenerators is still provided, so that those skilled in the art can understand the general process of preparing nanogenerators of the present invention, which is convenient The promotion and application of this technology: 1) Treat the surface of the stainless steel spring with 0.1mol / L dilute hydrochloric acid for 5 minutes to remove the oxide layer on the surface; 2) Coat the surface of the spring with a layer of zinc oxide seeds by sputtering or solution method layer (100-200nm); 3) Grow dense zinc oxide nanowire arrays on the surface of the sample by hydrothermal method. L, the reaction temperature is 95°C, and the reaction time is 5 hours; 4) After the reaction, the sample is taken out of the solution, dried, and coated with a polymethyl methacrylate insulat...

Embodiment 3

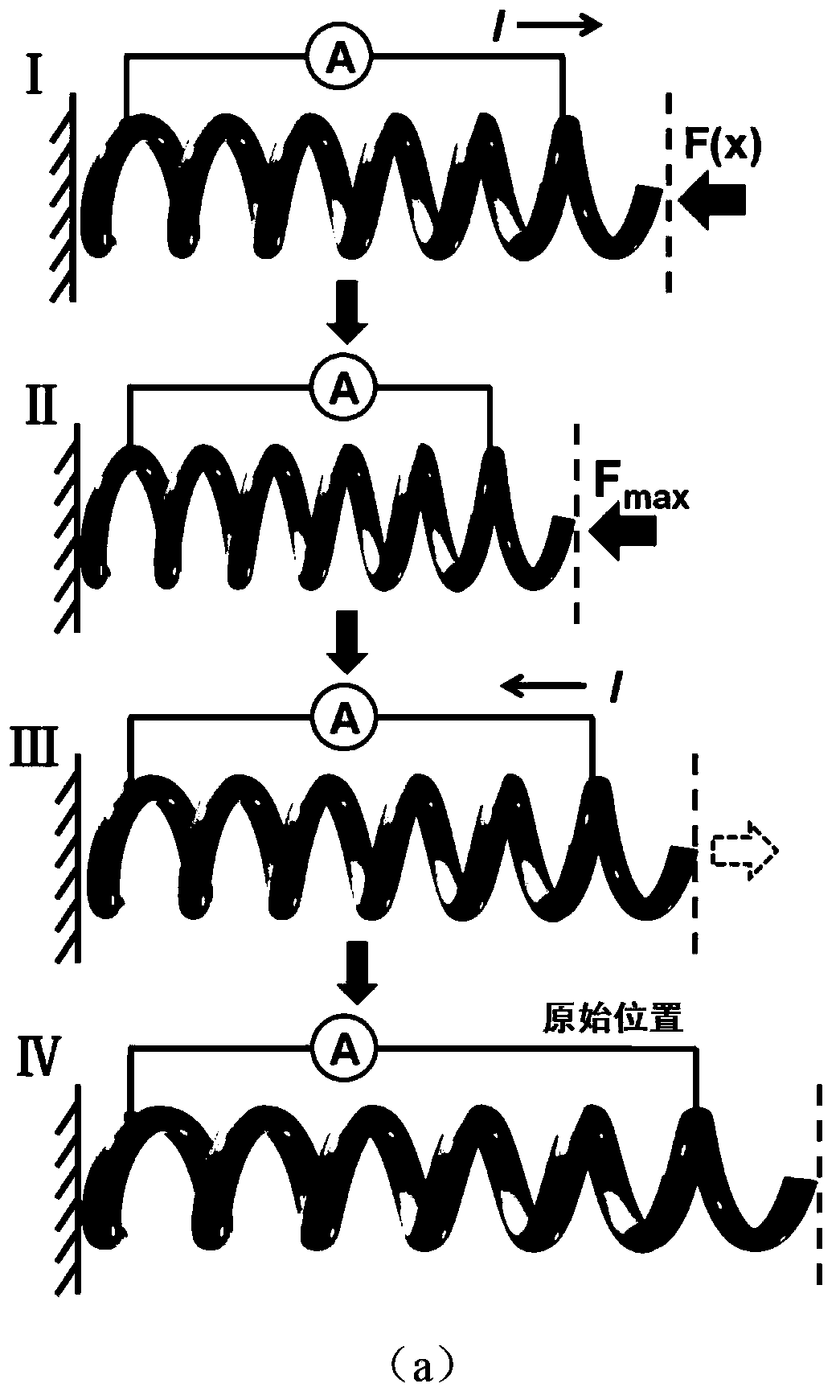

[0087] Embodiment 3: the measuring method of spring type nanogenerator

[0088] In order to measure the electrical signal output by the spring-type nanogenerator, the following methods can be used: 1) fix a square plastic plate (or other insulating materials) on the push rod of the linear motor; 2) place the spring-type nanogenerator Fix it on a vertical bracket so that the spring is perpendicular to the direction of the plastic plate; 3) Control the linear motor with a computer to compress the spring in a certain period; 4) Connect the lead wires from the inner and outer electrodes of the generator into the measuring device, and use The SR560 voltmeter of Stanford Research System was used to measure the open circuit voltage, and the SR570 ammeter was used to measure the short circuit current.

[0089] The output voltage and current data measured in the experiment are as follows Figure 8 As shown in -a and 8-b, it can be seen that under the action of periodic external force,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com