Array substrate, manufacturing method thereof, and display device

The technology of an array substrate and a manufacturing method is applied in the fields of an array substrate, a manufacturing method thereof and a display device, which can solve the problems of high manufacturing cost and complicated manufacturing process, and achieve the effects of low manufacturing cost and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

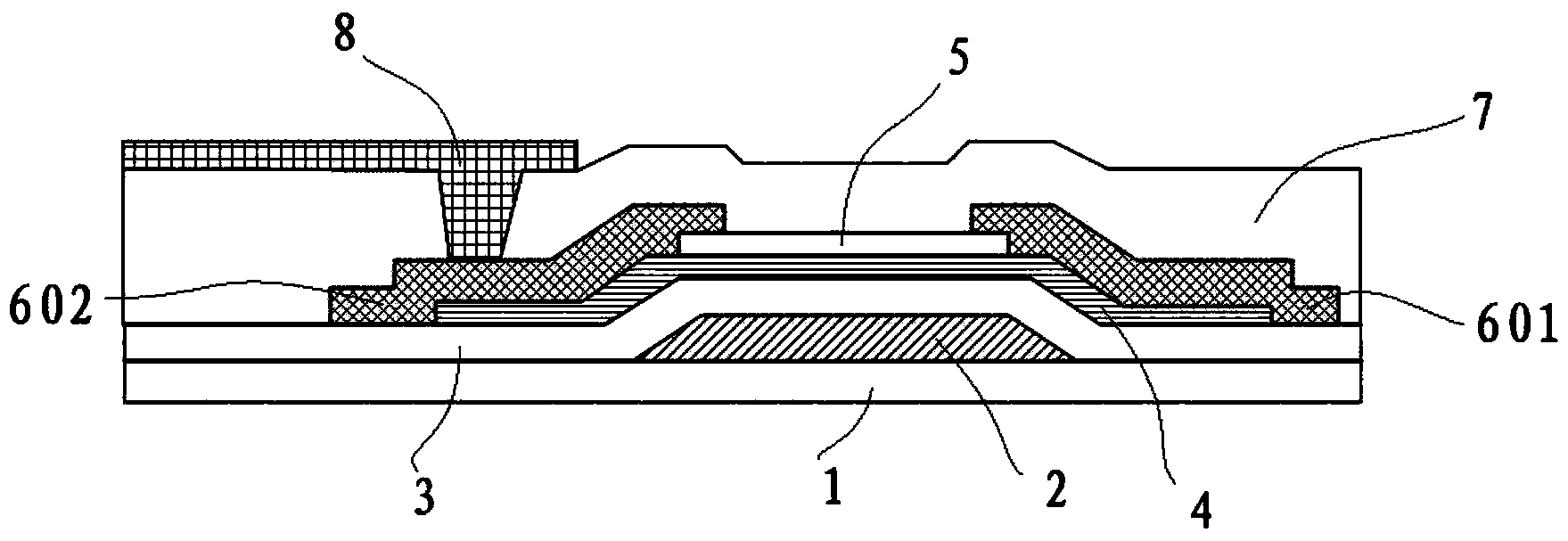

[0053] Such as figure 2 As shown, this embodiment provides an array substrate, the array substrate includes a thin film transistor area Q1 and a display area Q2, the thin film transistor area Q1 is provided with a thin film transistor, and the thin film transistor includes: a gate 2, a gate insulating layer 3, The active layer 4 , wherein the part of the active layer 4 corresponding to the gate 2 is the active region 401 . Wherein, the gate 2 is located on the substrate 1 , the gate insulating layer 3 covers the gate 2 , and the active layer 4 is located on the gate insulating layer 3 .

[0054]Preferably, the material of the active region 401 (of course, the material of the active layer 4 ) is metal oxide semiconductor. For example, its material may be indium gallium zinc oxide, indium zinc oxide or indium gallium tin oxide, preferably indium gallium zinc oxide or indium zinc oxide; the thickness of the active layer 4 is preferably between 10 nm and 100 nm. It should be no...

Embodiment 2

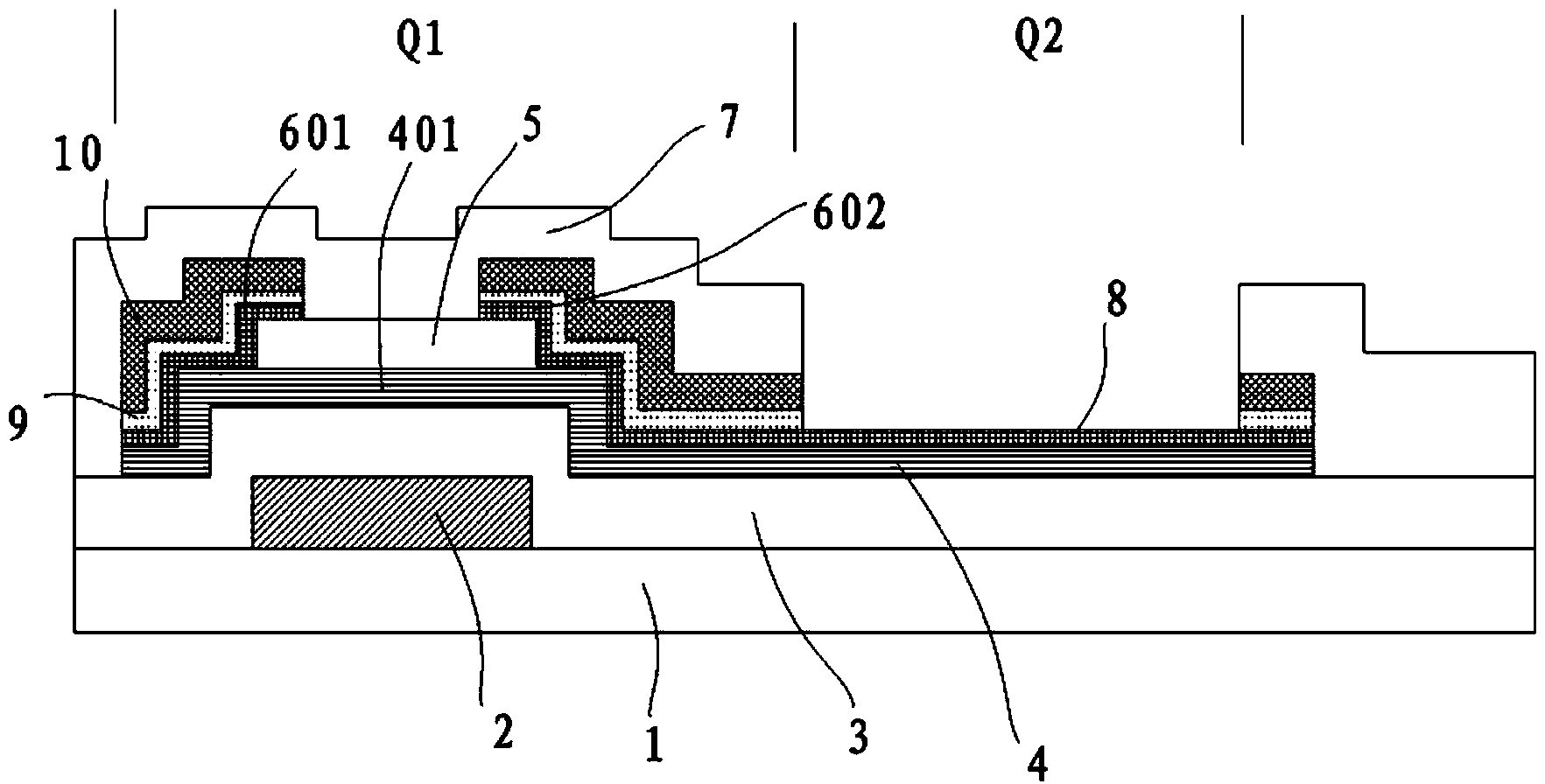

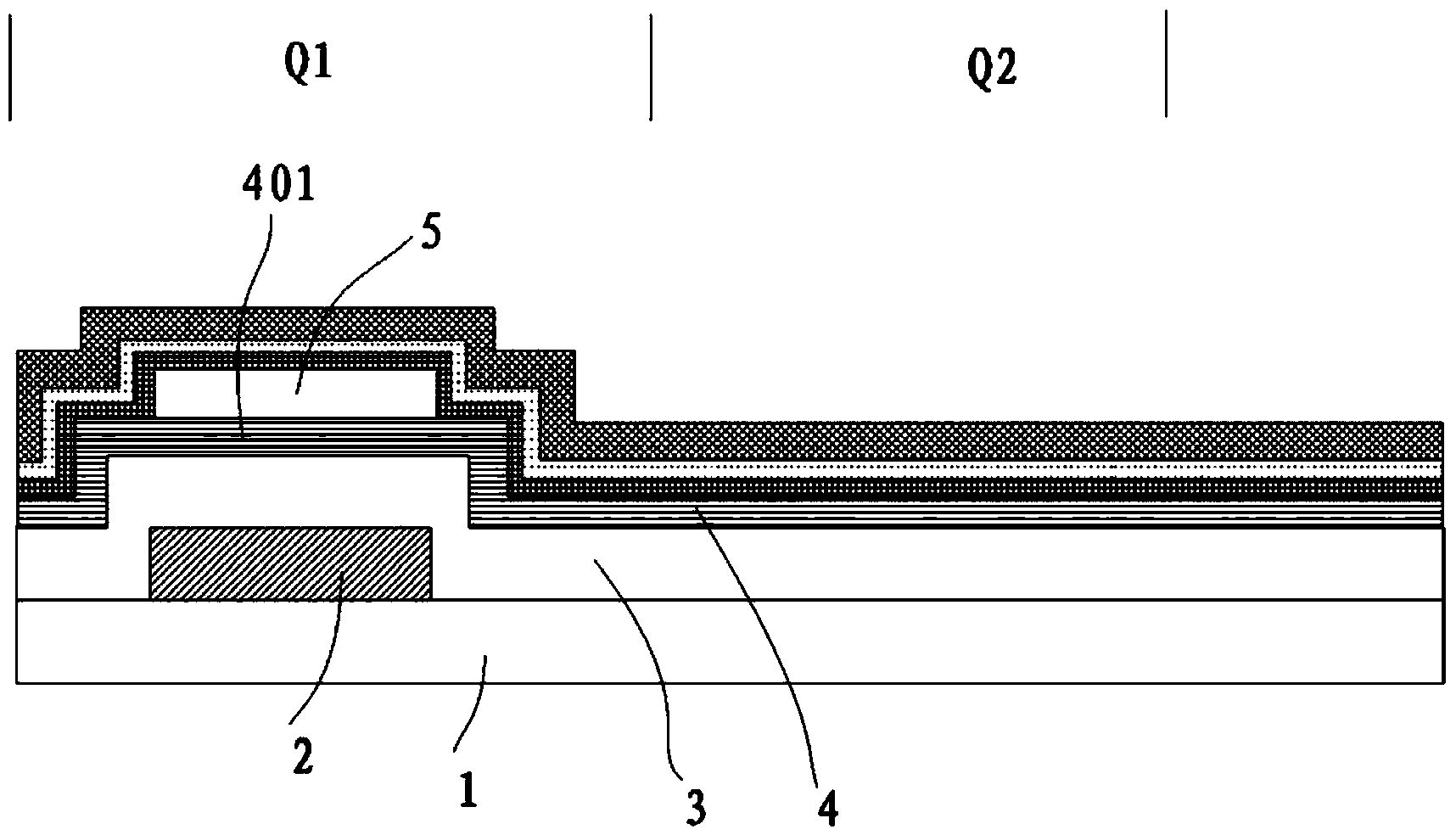

[0070] This embodiment provides a method for fabricating an array substrate, the array substrate comprising: a gate 2, a gate insulating layer 3, a source 601, a drain 602, a pixel electrode 8 and an active region 401, such as Figures 3 to 10 As shown, it specifically includes the following steps:

[0071] S01, forming a pattern including the gate 2 on the substrate 1 through a patterning process. The patterning process generally includes processes such as photoresist coating, exposure, development, etching, and photoresist stripping. Wherein, the material of the gate 2 is formed by one or more materials selected from molybdenum (Mo), molybdenum-niobium alloy (MoNb), aluminum (Al), aluminum-neodymium alloy (AlNd), titanium (Ti), and copper (Cu). single-layer or multi-layer composite laminates. It is preferably a single-layer or multi-layer composite film composed of molybdenum (Mo), aluminum (Al) or an alloy containing molybdenum (Mo) and aluminum (Al); the preferred thickn...

Embodiment 3

[0109] This embodiment provides a display device, which includes the array substrate described in Embodiment 1. The display device may be any product or component with a display function such as a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

[0110] The display device of this embodiment has the array substrate in Embodiment 1, so its manufacturing process is simple and its manufacturing cost is low.

[0111] Certainly, the display device of this embodiment may also include other conventional structures, such as a power supply unit, a display driving unit, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com