Nickel-plated steel strip and preparation method thereof

A technology of nickel-plated steel and cold-rolled steel strip, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve problems such as affecting corrosion resistance and welding performance, changing material resistance, etc. and welding performance improvement, bonding force enhancement, corrosion resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

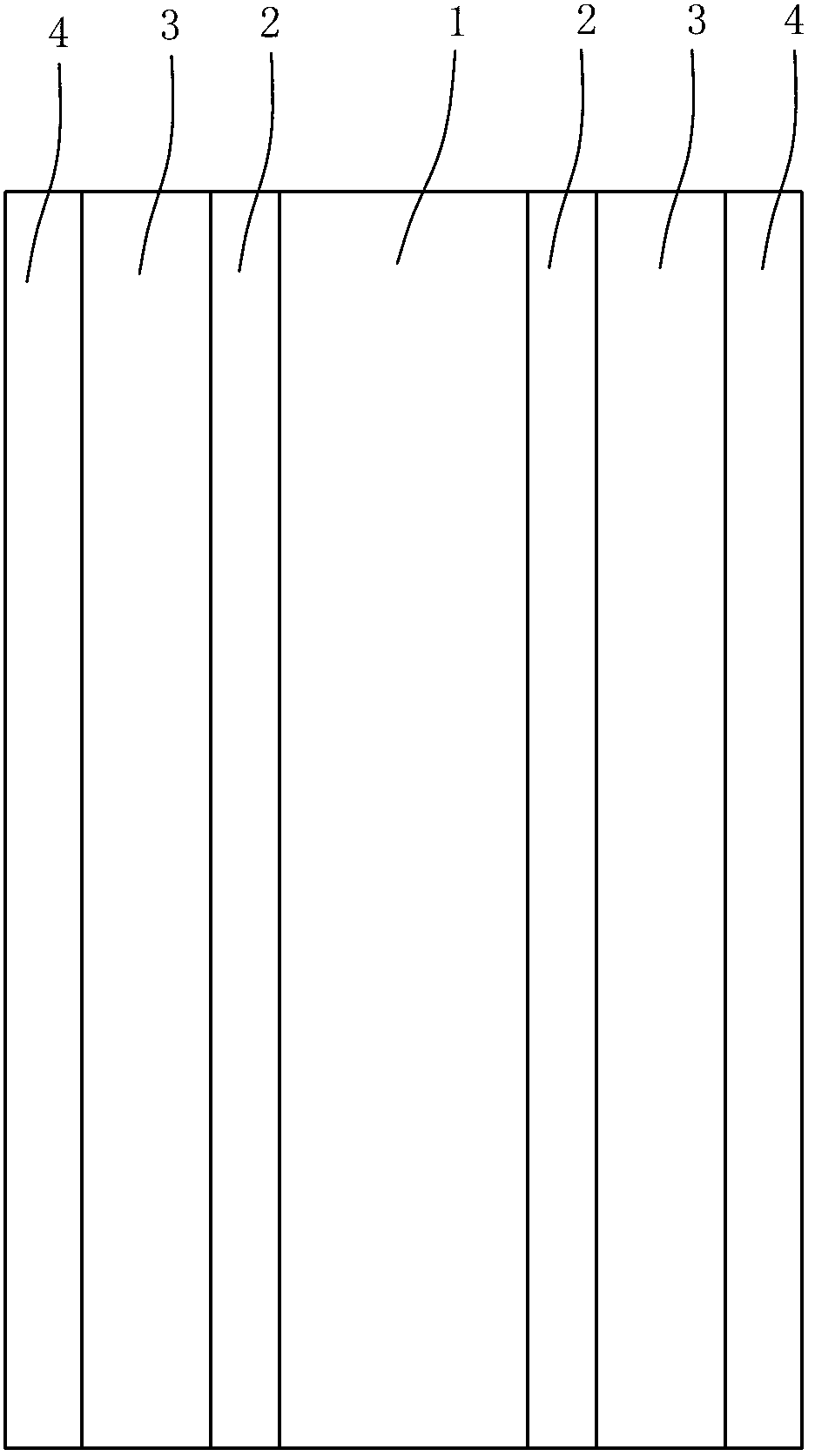

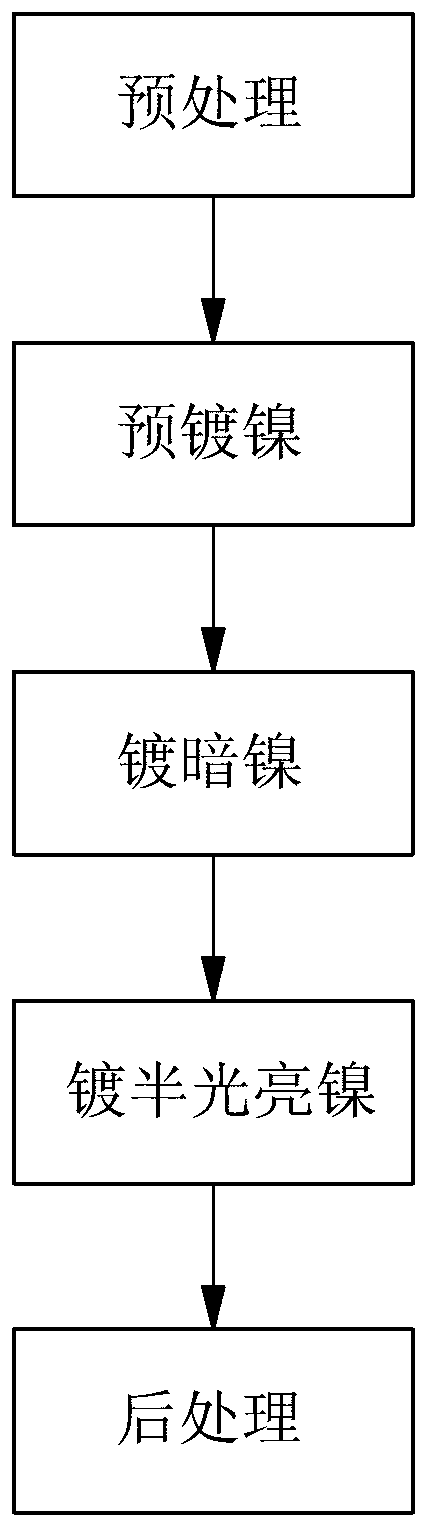

[0025] The present invention also discloses the preparation method of the above-mentioned nickel-plated steel strip, which comprises the following steps:

[0026] 1. Preprocessing steps

[0027] Pretreatment is carried out on the original steel base strip to be plated. The pretreatment mainly includes the following treatments in sequence: chemical degreasing, electrolytic degreasing, hot water washing, immersion activation in sulfuric acid or hydrochloric acid solution, and pure water washing. Among them, the control parameters of the above steps are as follows:

[0028] 1. Chemical degreasing

[0029] The degreasing fluid includes the following components: NaOH 60±5 g / L, NaOH 2 CO 3 30±5g / L and Na 3 PO 4 40±5g / L;

[0030] Temperature: 65±5℃;

[0031] 2. Electrodegreasing

[0032] The degreasing fluid includes the following components: NaOH 45±5 g / L, NaOH 3 PO 4 30±5g / L;

[0033] Electrolytic oil temperature: 65±5℃;

[0034] Current density: 5-10 A / dm 2 ;

[...

Embodiment

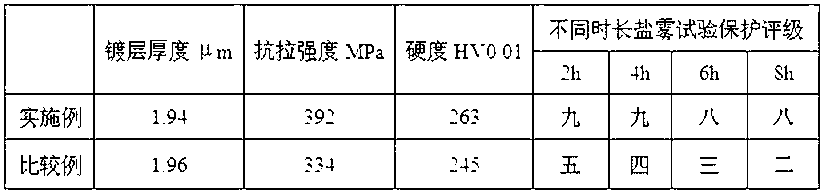

[0077] 1. Select SPCE with a thickness of 0.25mm as the steel base belt.

[0078] In order to make the bonding force between the steel base strip and the coating stronger, the original steel base strip to be plated should be pretreated, including chemical degreasing, electrolytic degreasing, hot water washing, immersion activation in a solution containing sulfuric acid, and after washing with pure water. Enter the electroplating operation. Wherein the control parameters of the above steps are as follows:

[0079] Chemical degreasing fluid composition: NaOH 60 g / L, NaOH 2 CO 3 30 g / L, Na 3 PO 4 40g / L;

[0080] Chemical degreasing fluid temperature: 65±5℃;

[0081] Chemical degreasing time: 3~5 min;

[0082] Electrolytic degreasing fluid composition: NaOH 45 g / L, NaOH 3 PO 4 30g / L;

[0083] Electrolytic oil temperature: 65±5℃;

[0084] Electrolytic degreasing time: 3~5 min;

[0085] Current density: 5-10 A / dm 2 ;

[0086] Hot water washing temperature: around 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com