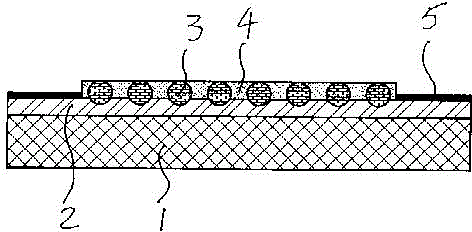

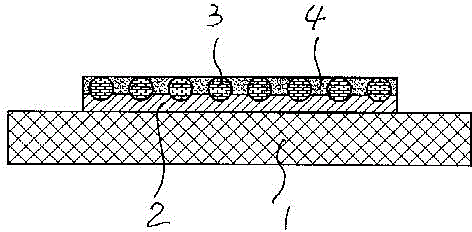

Uncovering-free type macromolecule self-adhesion waterproof roll and preparing method thereof

A self-adhesive waterproof membrane, polymer technology, used in chemical instruments and methods, mining equipment, layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]First, take 12 parts by weight of plasticizer naphthenic oil KA105 and pour it into the reaction kettle, start the agitator, and heat it to 185°C; then take 50 parts by weight of tackifier H-15 small molecular weight polyisobutylene, 25 parts by weight of SBS resin, the SIS resin of 15 parts by weight, the light absorber titanium dioxide of 4.0 parts by weight and the calcium carbonate filler of 1.0 parts by weight are poured in the reaction kettle, keep the temperature in the reaction kettle at 185 ℃, close the stirrer after continuing 55min and make auto Glue, and then pour the colloid into the mold to cool to room temperature, cut the self-adhesive block, wrap it with release paper, and then get the self-adhesive used as the self-adhesive layer of the peel-off polymer self-adhesive waterproof membrane.

Embodiment 2

[0040] First, take 10 parts by weight of the plasticizer naphthenic oil KN4010 and pour it into the reaction kettle, start the agitator, and heat it to 170°C; then take 45 parts by weight of the tackifier H-15 small molecular weight polyisobutylene, 22 parts by weight of SBS resin, 16 parts by weight of SIS resin, 3.0 parts by weight of light absorbing agent titanium dioxide and 2.0 parts by weight of calcium carbonate are poured into the reactor, and the temperature in the reactor is kept at 170 ° C. After 60 minutes, close the agitator to make self-adhesive Then pour the colloid into the mold to cool to room temperature, cut the self-adhesive block, wrap it with release paper, and then get the self-adhesive used as the self-adhesive layer of the peel-off polymer self-adhesive waterproof membrane.

Embodiment 3

[0042] First, take 8 parts by weight of plasticizer naphthenic oil KN4006 and pour it into the reaction kettle, start the agitator, and heat it to 180°C; then take 55 parts by weight of tackifier H-50 small molecular weight polyisobutylene, 28 parts by weight of SBS resin, 18 parts by weight of SIS resin, 2.0 parts by weight of light absorbing agent titanium dioxide and 3.0 parts by weight of calcium carbonate are poured into the reaction kettle, and the temperature in the reaction kettle is kept at 180 ° C. After 60 minutes, close the agitator to make self-adhesive Then pour the colloid into the mold to cool to room temperature, cut the self-adhesive block, wrap it with release paper, and then get the self-adhesive used as the self-adhesive layer of the peel-off polymer self-adhesive waterproof membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com