An intumescent halogen-free flame-retardant high isotactic polybutene-1 material and its preparation method

A high isotactic polybutene, expansion type technology, applied in the field of isotactic polybutene-1 material and its preparation, halogen-free flame retardant materials, can solve the problems of life and property hazards, hinder firefighters' rescue work, etc., and achieve broad application The effect of small range, small mechanical properties and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This example provides an intumescent halogen-free flame-retardant high-isotactic polybutene-1 material, which is composed of the following raw materials in terms of weight percentage: polybutene-1 with an isotacticity of 93% is 89.8%, and the anti-oxidation Agent 225 is 0.2%, flame retardant FP-2100J is 10%. The used twin-screw extruder has a diameter of 25 cm, an aspect ratio of 1:32, and a processing temperature of 170°C to 185°C.

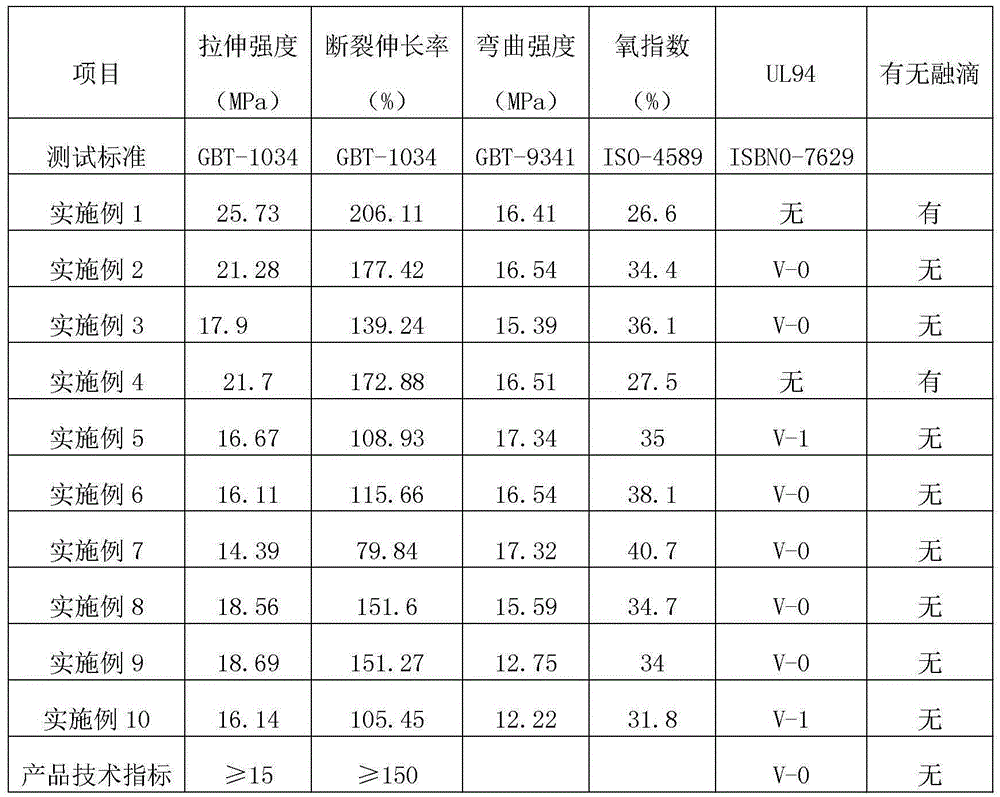

[0047] The intumescent halogen-free flame-retardant high isotactic polybutene-1 material of this example was prepared according to the above preparation method and molded for performance testing. The test results are shown in Table 1.

Embodiment 2

[0049] This example provides an intumescent halogen-free flame-retardant high isotactic polybutene-1 material, which is composed of the following raw materials in terms of weight percentage: polybutene-1 with an isotacticity of 93% is 79.8%, and the anti-oxidation Agent 225 is 0.2%, flame retardant FP-2100J is 20%. The used twin-screw extruder has a diameter of 25 cm, an aspect ratio of 1:32, and a processing temperature of 170°C to 185°C.

[0050] The intumescent halogen-free flame-retardant high isotactic polybutene-1 material of this example was prepared according to the above preparation method and molded for performance testing. The test results are shown in Table 1.

Embodiment 3

[0052] This example provides an intumescent halogen-free flame-retardant high-isotactic polybutene-1 material, which is composed of the following raw materials in terms of weight percentage: polybutene-1 with an isotacticity of 93% is 74.8%, and the anti-oxidation Agent 225 is 0.2%, flame retardant FP-2100J is 25%. The used twin-screw extruder has a diameter of 25 cm, an aspect ratio of 1:32, and a processing temperature of 170°C to 185°C.

[0053] The intumescent halogen-free flame-retardant high isotactic polybutene-1 material of this example was prepared according to the above preparation method and molded for performance testing. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com