Electroconductive polymer solution, electroconductive polymer composition, solid electrolytic capacitor therewith and method for producing same ?

A conductive polymer and solid electrolysis technology, which is applied in the direction of solid electrolytic capacitors, electrolytic capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problems that the properties and heat resistance of conductive polymer films are not always sufficient, and achieve excellent dispersibility performance, excellent heat resistance, and excellent reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

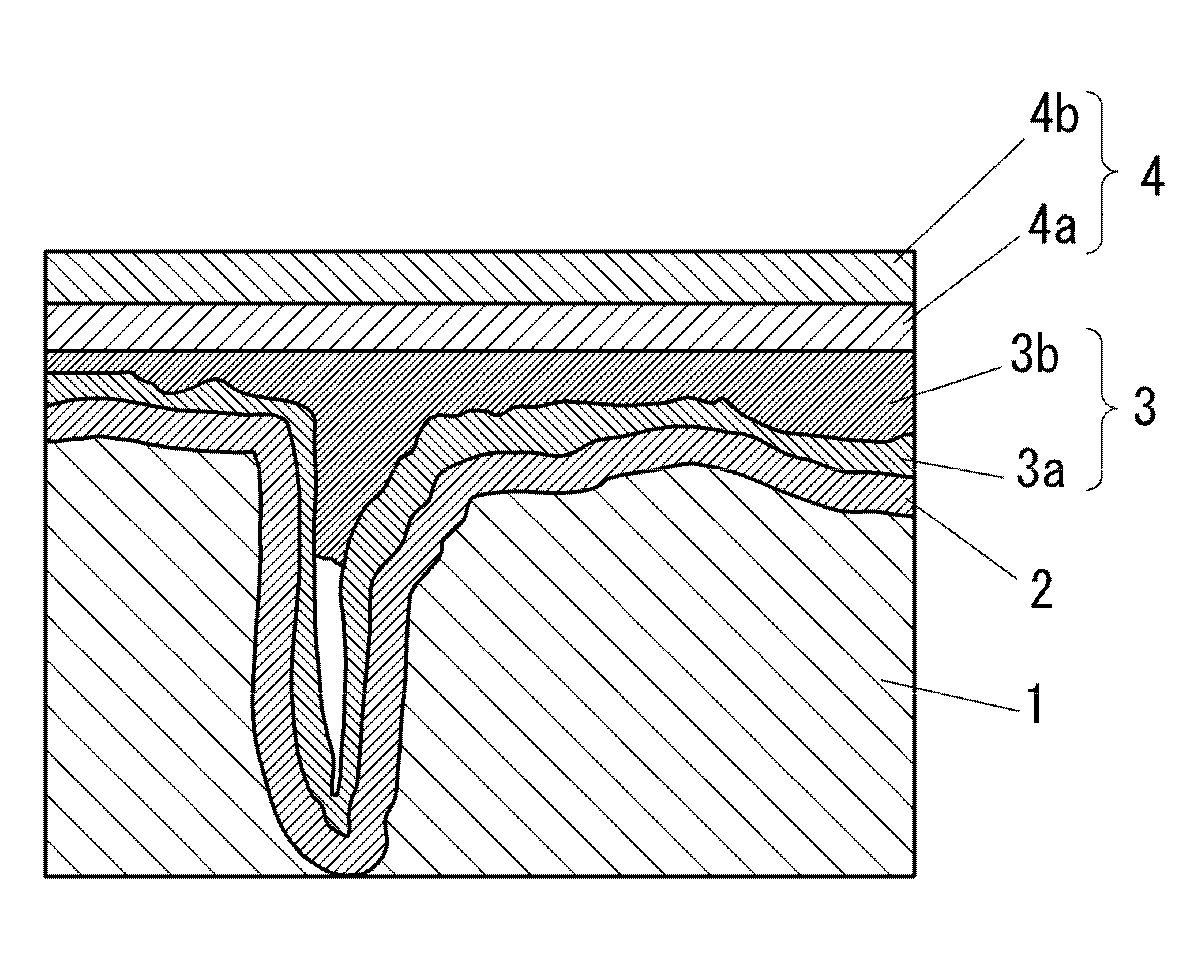

[0098] refer to figure 1 , to illustrate Embodiment 1 of the present invention. A 3×4 mm porous aluminum foil subjected to a surface area increasing treatment by etching was used as the anode conductor 1 . The immersion of the anode conductor 1 into the tank containing the monomer solution, dopant and oxidant solution is repeated several times, and a poly-3,4-substance containing poly-3,4-substrate is formed inside the pores of the porous body of the anode conductor 1 by a chemical polymerization method. A conductive polymer composition of ethylenedioxythiophene to form the first solid electrolyte layer 3a.

[0099] Subsequently, 1.1 g of 3,4-ethylenedioxythiophene was supplied to a mixture solution of 100 g of pure water and 5.9 g of 20% by mass polystyrenesulfonic acid (weight average molecular weight: 50000), and stirring was performed at normal temperature for 5 minutes. Subsequently, 5.0 g of a 40% by mass ammonium persulfate aqueous solution was supplied at 1 ml / min, a...

Embodiment 2

[0104] Except for setting the amount of 2-amino-2-hydroxymethyl-1,3-propanediol as the first compound to 0.20 g, a conductive polymer solution was obtained in the same manner as in Example 1, and a capacitor element was prepared . The resulting conductive polymer solution was dark blue and had a pH of 4.68.

Embodiment 3

[0106] Except for setting the amount of 2-amino-2-hydroxymethyl-1,3-propanediol as the first compound to 0.30 g, a conductive polymer solution was obtained in the same manner as in Example 1, and a capacitor element was prepared . The resulting conductive polymer solution was dark blue and had a pH of 6.11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com