Process and devices for chemical modification of cellulose and for continuous low temperature solution spinning

A technology of low-temperature dissolution and chemical modification, which is applied to artificial filaments made of cellulose derivatives, chemical characteristics of fibers, and complete sets of equipment for the production of artificial threads. High consumption and other problems, to achieve good dissolution effect, improve the properties of cellulose fibers, and improve the spinning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

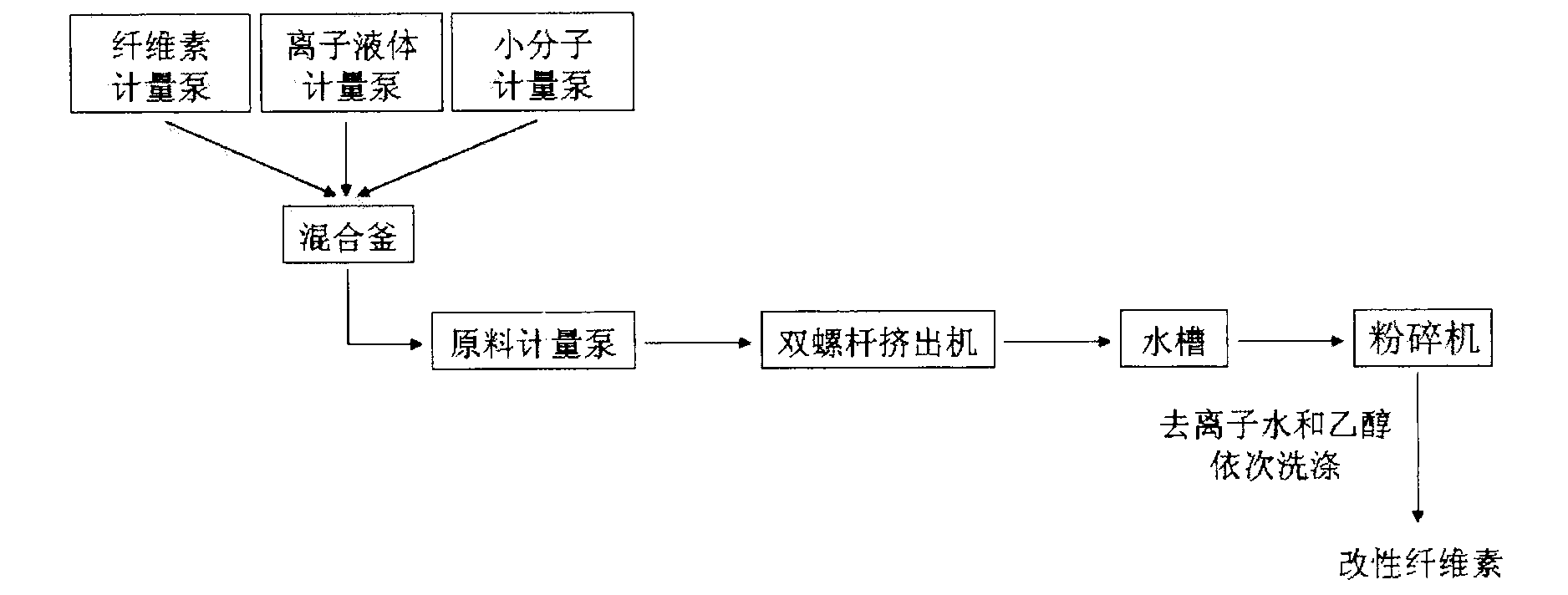

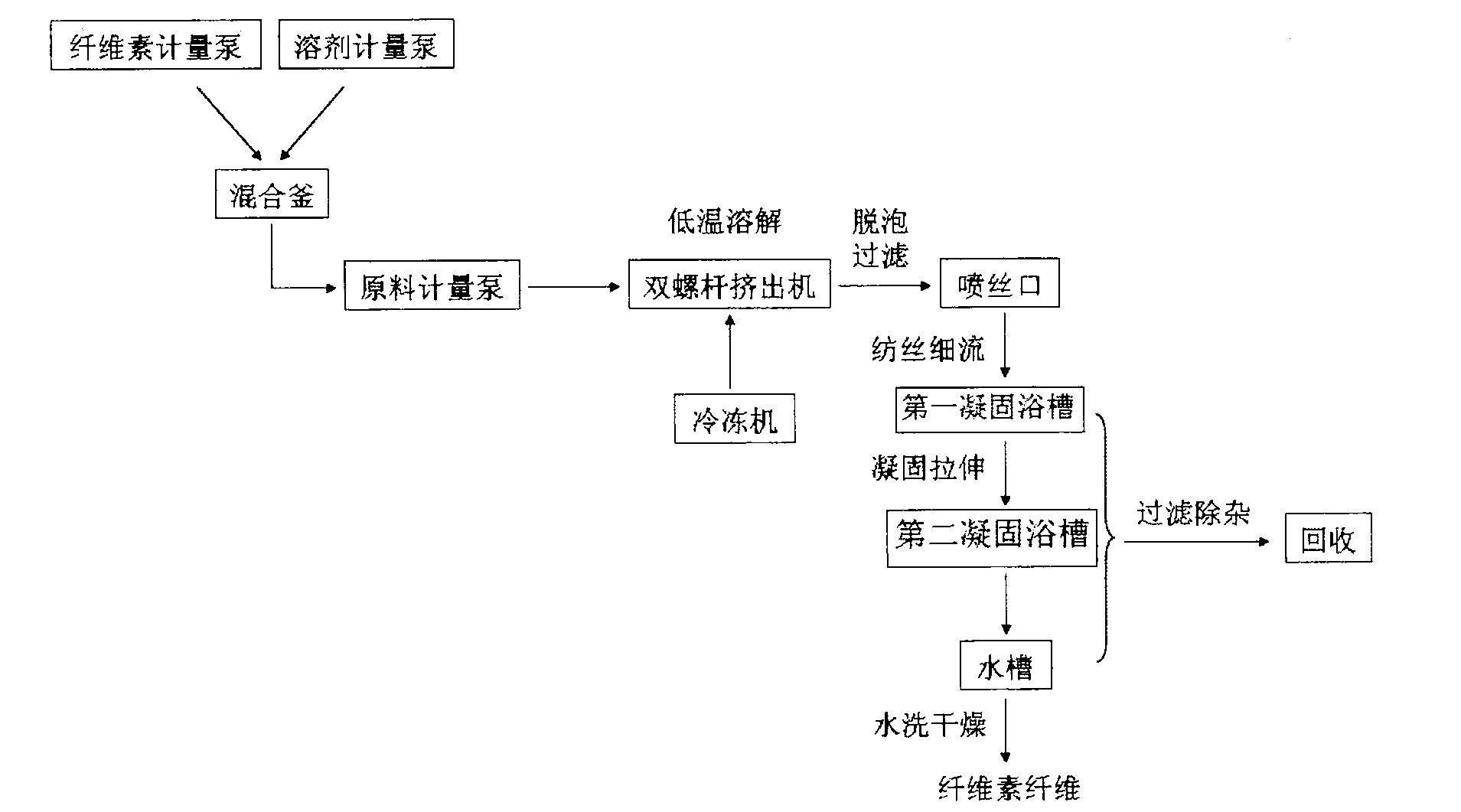

[0027] A chemical modification of cellulose and continuous low-temperature solution spinning equipment is composed of a chemical modification device and a continuous low-temperature solution spinning device. Such as figure 1 As shown, the chemical modification device includes a cellulose metering pump, an ionic liquid metering pump, a small molecule metering pump, a mixing kettle, a raw material metering pump, a twin-screw extruder, a water tank and a pulverizer; figure 2As shown, the continuous low-temperature solution spinning device includes a cellulose metering pump, a solvent metering pump, a mixing tank, a raw material metering pump, a twin-screw extruder and a spinning assembly, and the spinning assembly includes a spinning nozzle , the first coagulation bath, the second coagulation bath and the sink. The temperature controllers on each section of the twin-screw extruder of the continuous low-temperature melting spinning device are connected to a low-temperature cooli...

Embodiment 2

[0033] A kind of chemical modification of cellulose and continuous low temperature solution spinning method, adopt the chemical modification of the cellulose in embodiment 1 and continuous low temperature solution spinning equipment, concrete steps are:

[0034] The first step: the ordinary cotton cellulose and phthalic anhydride that the degree of polymerization is 550 are vacuum-dried for 24 hours at 70° C. and a vacuum degree of 100 Pa, and 1.5 kg of vacuum-dried cotton cellulose, 0.75 kg of vacuum The dried phthalic anhydride and 4kg [BMIM]Cl are metered by cellulose metering pump, small molecule metering pump and ionic liquid metering pump respectively, then added to the mixing tank and mixed evenly, then metered by the raw material metering pump and passed through the same direction Extruded by a twin-screw extruder, the length-to-diameter ratio of the screw is 1:35, and the temperature of each section of the extruder is 100°C, 110°C, 120°C, 120°C, 130°C, 130°C, 140°C, 15...

Embodiment 3

[0038] A kind of chemical modification of cellulose and continuous low temperature solution spinning method, adopt the chemical modification of the cellulose in embodiment 1 and continuous low temperature solution spinning equipment, concrete steps are:

[0039] The first step: ordinary cotton cellulose and urea with a degree of polymerization of 580 are vacuum-dried for 24 hours at 70° C. and a vacuum of 96 Pa, and 1 kg of vacuum-dried cotton cellulose, 0.75 kg of vacuum-dried urea, 3kg [BMIM]Cl was metered by the cellulose metering pump, the small molecule metering pump and the ionic liquid metering pump respectively, and then added to the mixing tank and mixed evenly, and then extruded through the co-rotating twin-screw extruder after being metered by the raw material metering pump. The length-diameter ratio of the screw is 1:44, the temperature of each section of the extruder is 100°C, 110°C, 120°C, 120°C, 130°C, 140°C, 150°C, 160°C, and the screw speed is 80rpm. Wash the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com