Perovskite structure lead titanate single crystal nano-sheet preparation method

A perovskite structure, single crystal nanotechnology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of small structural anisotropy, difficult to achieve two-dimensional nanostructure preparation, and difficult to achieve oriented growth and other issues, to achieve the effect of easy large-scale production, low cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Dissolve 6mmol of tetrabutyl titanate in 60ml of absolute ethanol, then drop it into deionized water to precipitate titanium hydroxide, and wash it with deionized water;

[0022] 2) Add the precipitated titanium oxyhydroxide prepared in step 1) to a potassium hydroxide solution with a concentration of 8 mol / L to obtain a suspension;

[0023] 3) Stir the suspension prepared in step 2) for 30 minutes, then transfer it to a hydrothermal reaction kettle, adjust it with deionized water so that its volume accounts for 4 / 5 of the reaction kettle volume, seal it, and perform a hydrothermal reaction at 200°C for 16 hours , cooled in air, lowered to room temperature, took out the reaction product, filtered, washed with deionized water and absolute ethanol in turn, and dried at 80°C to obtain K 2 Ti 6 o 13 nanowire powder;

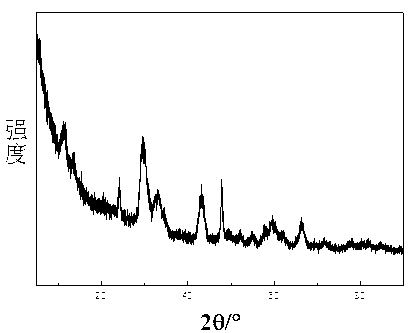

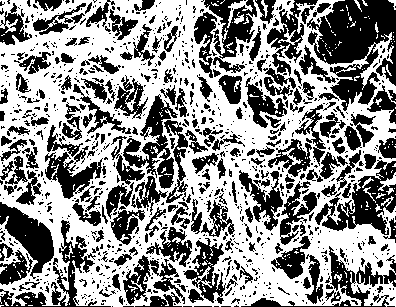

[0024] K 2 Ti 6 o 13 See the XRD pattern of figure 1 , its diffraction peak can basically be calibrated as the K of the monoclinic phase 2 Ti 6 o ...

Embodiment 2

[0030] 1) Dissolve 3mmol of tetrabutyl titanate in 60ml of absolute ethanol, then drop it into deionized water to precipitate titanium hydroxide, and wash it with deionized water;

[0031] 2) Add the precipitated titanium oxyhydroxide prepared in step 1) into a potassium hydroxide solution with a concentration of 4 mol / L to obtain a suspension;

[0032] 3) After stirring the suspension prepared in step 2) for 2 hours, transfer it to a hydrothermal reaction kettle, adjust it with deionized water to make the volume account for 2 / 3 of the reaction kettle volume, seal it, and after 32 hours of hydrothermal reaction at 200°C, Cool in air, drop to room temperature, take out the reaction product, filter, wash with deionized water and absolute ethanol in turn, and dry at 80°C to obtain K 2 Ti 6 o 13 nanowire powder;

[0033] 4) Under stirring, dissolve lead nitrate in deionized water, Pb 2+ The ion concentration is adjusted to 0.189mol / L;

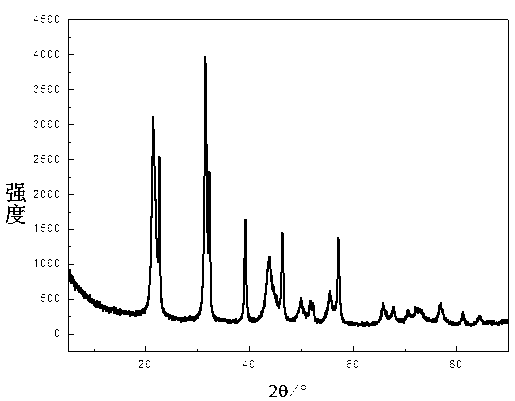

[0034] 5) Under stirring, the K obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com