Nuclear power halogen-free, low-smoke and flame-retardant cable sheath material with high elongation and long service life and preparation method thereof

A cable sheathing material, low-smoke flame-retardant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem of the decrease of tensile strength and elongation at break, the weakening of the physical and mechanical properties of the sheath, and the decrease of the melt index of the cable material, etc. problems, to achieve the effect of improving compatibility, high strength, and good thermal oxygen aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Halogen-free, low-smoke, flame-retardant, high-elongation, long-life cable sheathing material for nuclear power, composed of the following components by weight: 100 parts of resin base material, 100-150 parts of composite flame retardant, synergistic flame retardant 5-25 parts, 3-20 parts of the first interfacial compatibilizer, 1.5-4 parts of composite antioxidant, 2-5 parts of lubricant;

[0031] The resin base material is composed of any two or more of ethylene-vinyl acetate copolymer, linear low-density polyethylene, ethylene-octene elastomer and a second interfacial compatibilizer, wherein the ethylene-vinyl acetate copolymer The parts by weight are 30-60 parts, the parts by weight of linear low density polyethylene are 20-50 parts, the parts by weight of ethylene-octene elastomer are 10-30 parts, and the parts by weight of the second interface compatibilizer are 10-50 parts. 30 parts, composed of maleic anhydride graft and silicone masterbatch;

[0032] The compo...

Embodiment 2

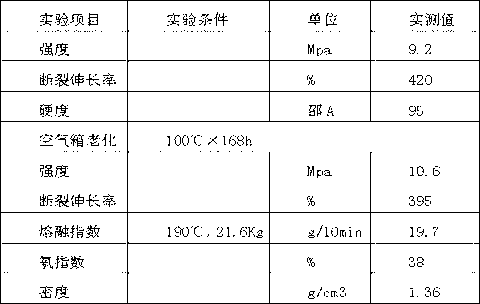

[0047] The purpose of this example is to provide a kind of halogen-free, low-smoke, flame-retardant, high-elongation and long-life cable sheath material for nuclear power, with an elongation of 420%, a strength of 9.2 Mpa, and a hardness of 95. It has excellent processing performance and is easy to extrude. .

[0048] Halogen-free, low-smoke, flame-retardant, high-elongation, long-life cable sheathing material for nuclear power, its raw materials include: main matrix composed of ethylene vinyl acetate copolymer, linear low-density polyethylene and ethylene octene elastomer Anhydride grafted POE material and silicone masterbatch are used as interfacial compatibilizer, flame retardant system composed of aluminum hydroxide, magnesium hydroxide, zinc borate, lubrication system composed of silicone oil, polyethylene wax and zinc stearate, high Low-temperature compound antioxidant as an anti-aging system.

[0049] The raw materials of the above-mentioned cable sheath materials incl...

Embodiment 3

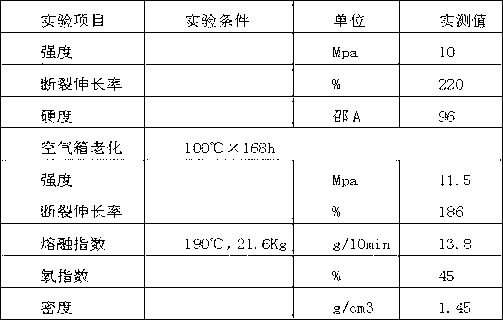

[0065] The purpose of this embodiment is to provide a halogen-free, low-smoke, flame-retardant, high-elongation, long-life cable sheath material for nuclear power, with an oxygen index of 45%, a strength of 10 Mpa, and an elongation of 220%. The cable has passed the flame retardant Class A bunching burning test.

[0066] Halogen-free, low-smoke, flame-retardant, high-elongation, long-life cable sheathing material for nuclear power, its raw materials include: main matrix composed of ethylene vinyl acetate copolymer, linear low-density polyethylene and ethylene-octene elastomer Anhydride-grafted EVA material and silicone masterbatch are used as interface compatibilizers, a flame retardant system composed of aluminum hydroxide, magnesium hydroxide, zinc borate and nitrogen-phosphorus intumescent nano-composite flame retardants, polyethylene wax and Lubricating system composed of zinc stearate, anti-aging system composed of a high and low temperature resistant compound antioxidant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com