Diode testing device and use method thereof

A test device, diode technology, applied in the direction of measuring device shell, single semiconductor device test, etc., can solve the problems of test data error, loose fixation, mechanical damage, etc., achieve stable and reliable data, improve test reliability, and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

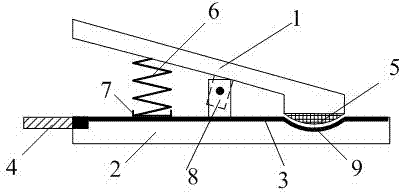

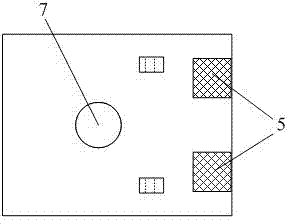

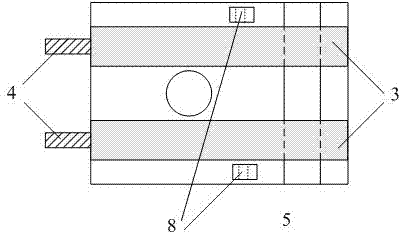

[0019] A diode testing device, which includes an upper splint 1, a lower splint 2 and two metal electrodes 3, the two metal electrodes 3 are electrically connected to two terminal posts 4 at the left end of the lower splint 2, and there are springs 6 and supports between the upper and lower splints Column 8, the right end of the lower splint 2 has a groove 9, and the right end of the upper splint 1 has two protrusions 5, and the protrusions 5 are placed in the groove 9 。

[0020] The groove 9 is arc-shaped, and the shape of the protrusion 5 corresponds to the shape of the groove 9 and has the same size, so as to ensure that the protrusion 5 can be in close contact with the groove 9 .

[0021] The protrusion 5 adopts an elastic rubber protrusion to ensure that the pins of the diode are not damaged while crimping the diode under test.

[0022] The width of the groove 9 is 10-15 times the diameter of the tested diode shell, and the depth is 3-5 times the diameter of the tested d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com