Secondary-battery porous-membrane slurry, secondary-battery porous membrane, secondary-battery electrode, secondary-battery separator, secondary battery, and method for manufacturing secondary-battery porous membrane

A secondary battery, porous membrane technology, applied in the field of secondary battery porous membrane slurry, can solve problems such as explosion, short circuit of positive and negative electrodes, and achieve the effects of excellent dispersibility, prevention of detachment, and excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0300]

[0301] 100 parts of styrene, 1.0 parts of sodium dodecylbenzenesulfonate, 100 parts of ion-exchanged water, and 0.5 parts of potassium persulfate were placed in a reactor equipped with a stirrer, and polymerized at 80° C. for 8 hours. Thus, an aqueous dispersion of seed polymer particles A having an average particle diameter of 60 nm was obtained.

[0302]

[0303] Put the aqueous dispersion of the seed polymer particles A obtained in the step (1) into a reactor with a stirrer as 2 parts, dodecylbenzene, and 0.2 parts of sodium sulfonate, 0.5 parts of potassium persulfate, and 100 parts of ion-exchanged water were mixed to obtain a mixture, and the temperature was raised to 80°C. On the other hand, 97 parts of styrene, 3 parts of methacrylic acid, 4 parts of t-dodecyl mercaptan, 0.5 parts of sodium dodecylbenzenesulfonate, and 100 parts of ion-exchanged water were mixed in another container to prepare a single A dispersion of a mixture of solids. The dispersion ...

Embodiment 2

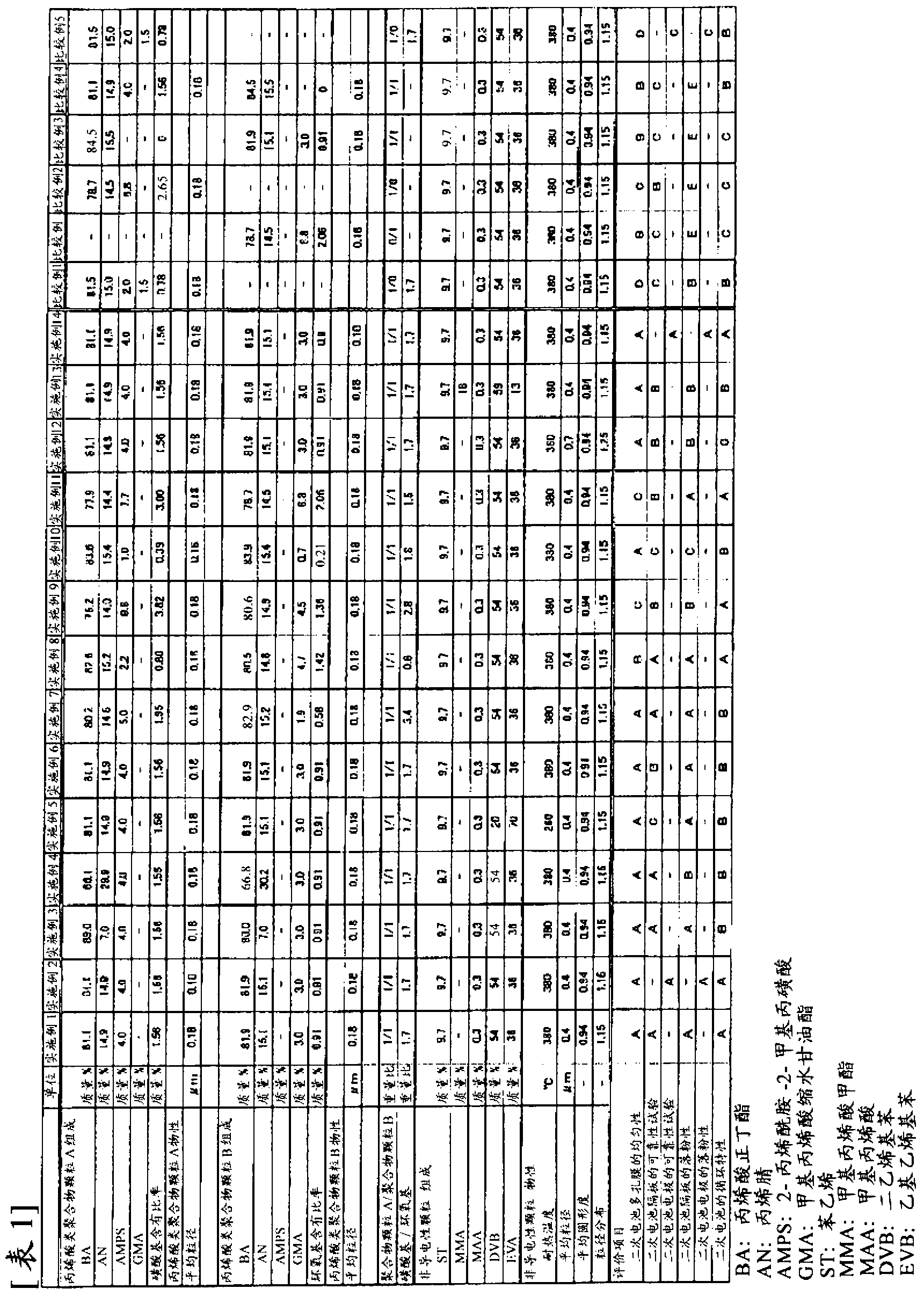

[0330] On one side of the negative electrode active material layer side of the negative electrode obtained in the operation (8) of Example 1, apply the porous film slurry obtained in the operation (6) of Example 1 and obtain the slurry layer so that it completely covers the negative electrode active material layer and the thickness of the dried porous film is 5 μm. The slurry layer was dried at 50° C. for 10 minutes to form a porous membrane, thereby obtaining a negative electrode with a porous membrane. The obtained negative electrode with a porous membrane had a layer structure of (porous membrane) / (negative electrode active material layer) / (copper foil). The uniformity, reliability, and powder falling properties of the porous membrane of the obtained negative electrode with a porous membrane were evaluated. The results are shown in Table 1.

[0331] Instead of the organic separator with a porous membrane obtained in the step (9) of Example 1, an organic separator (a singl...

Embodiment 3

[0334] Instead of the acrylic polymer particles A obtained in the step (4) of Example 1, the following acrylic polymer particles A were used. In addition, instead of the acrylic polymer particles B obtained in the step (5) of Example 1, the following acrylic polymer particles B were used. Except for using the acrylic polymer particles A and the acrylic polymer particles B to produce a porous membrane slurry, the same operation as in Example 1 was performed to obtain and evaluate an organic separator with a porous membrane and a secondary battery. . The results are shown in Table 1. In addition, the weight ratio of the acrylic polymer particles A to the acrylic polymer particles B in the porous film slurry (acrylic polymer particles A / acrylic polymer particles B) was 1, and the sulfonic acid in the binder The weight ratio (sulfonic acid group / epoxy group) of the group to the epoxy group was 1.7.

[0335]

[0336] Put 300 parts of ion-exchanged water, 89.0 parts of n-butyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com