Ethylene propylene terpolymer superfine fibre and its preparation method and application

A technology of EPDM rubber and ultra-fine fiber, applied in wet spinning and other directions, can solve the problems of unfavorable electrospinning, high viscosity and surface tension, and achieve the elimination of spinning, high porosity and huge economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

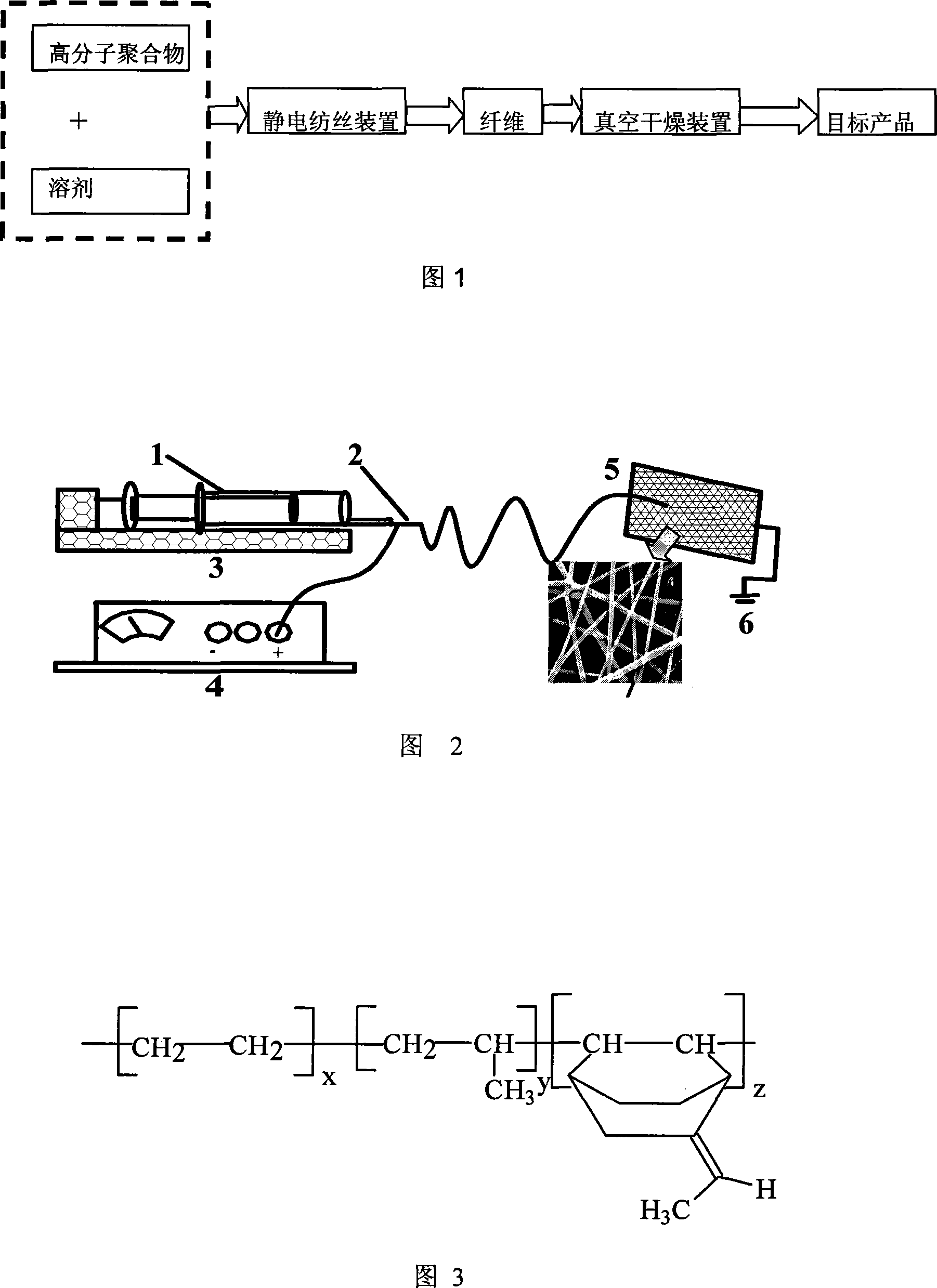

Method used

Image

Examples

Embodiment 1

[0038] (1) Prepare 10 ml of tetrahydrofuran / cyclohexane solution of 6% ethylene-propylene-diene rubber in a concentration of 6%, wherein the volume ratio of tetrahydrofuran / cyclohexane is 4:1, and stir at 60° C. for 24 hours to obtain a uniform solution , Transparent polymer solution, after cooling to room temperature, place it for 4 hours for defoaming.

[0039] (2) Take about 5 milliliters of the above-mentioned polymer solution, put it into a liquid storage device, remove air, and connect a spinneret (aperture 1.2 mm). Connect the spinneret to the positive pole of the high voltage power supply. Install a 10 cm x 10 cm aluminum foil collection device with a temperature of 30 °C. The collection device is grounded. Adjust the distance between the spinneret and the collecting device to be 16 cm. The ambient temperature for spinning is 30°C, including the temperature of the solution in the liquid storage device and the temperature of the collecting device are both 30°C.

[0...

Embodiment 2

[0043] (1) Prepare 10 ml of tetrahydrofuran solution of EPDM rubber with a mass percent concentration of 6%, stir at 60° C. for 24 hours to obtain a uniformly dissolved and transparent polymer solution, cool to room temperature and place for 4 hours for defoaming.

[0044] (2) Take about 5 milliliters of the above-mentioned polymer solution, put it into a liquid storage device, remove air, and connect a spinneret (aperture 1.2 mm). Connect the spinneret to the positive pole of the high voltage power supply. Install a 10 cm x 10 cm aluminum foil collection device with a temperature of 30 °C. The collection device is grounded. Adjust the distance between the spinneret and the collecting device to be 18 cm. The ambient temperature for spinning is 30°C, including the temperature of the solution in the liquid storage device and the temperature of the collecting device are both 30°C.

[0045] (3) Turn on the high-voltage power supply, adjust the voltage to 15Kv, and the air veloc...

Embodiment 3

[0048] (1) Prepare 10ml of tetrahydrofuran / xylene solution of EPDM rubber with a mass percentage concentration of 4%, wherein the volume ratio of tetrahydrofuran / xylene is 5:1, and stir at 60°C for 24 hours to obtain a uniform and transparent solution The polymer solution was cooled to room temperature and placed for 4 hours for degassing.

[0049] (2) Take about 5 milliliters of the above-mentioned polymer solution, put it into a liquid storage device, remove air, and connect a spinneret (aperture 1.2 mm). Connect the spinneret to the positive pole of the high voltage power supply. Install a 10 cm x 10 cm aluminum foil collection device with a temperature of 30 °C. The collection device is grounded. Adjust the distance between the spinneret and the collecting device to be 20 cm. The ambient temperature for spinning is 30°C, including the temperature of the solution in the liquid storage device and the temperature of the collecting device are both 30°C.

[0050] (3) Turn o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com