Method for increasing utilization ratio of additional value of high-temperature coal tar

A high-temperature coal tar and value-added technology, which is applied in refining to change the structure and skeleton of hydrocarbons, can solve the problems of wasting chemical product resources, low prices, and affecting the economic benefits of tar processing enterprises, achieving mild process conditions, increasing added value, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

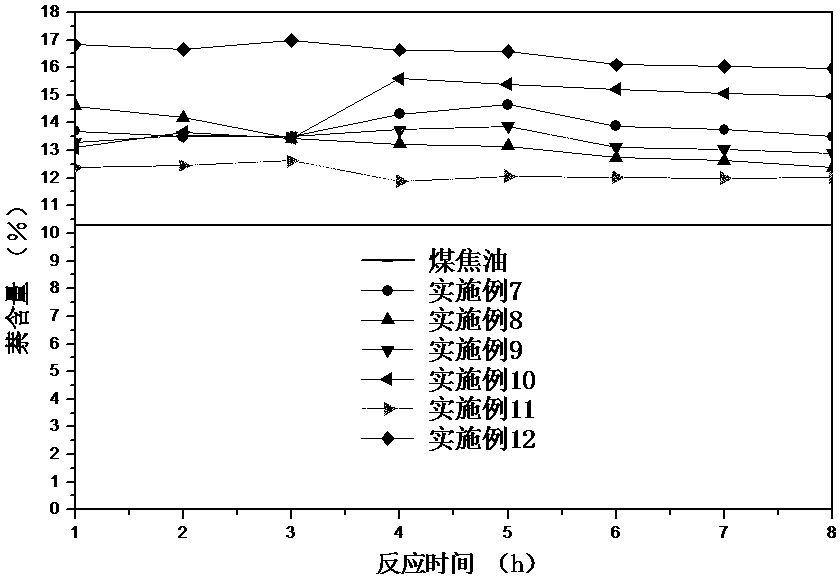

Embodiment 1

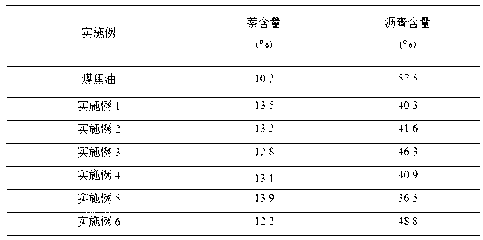

[0022] Add 0.09 g modified organomontmorillonite-supported metal nickel catalyst, 3.0 g coal tar, 1.5 g toluene solvent (the mass ratio of toluene / coal tar is 0.5) and 0.3 g n-dodecane internal standard ( The amount of internal standard added is 10 wt% of the weight of coal tar). After sealing, first use H 2 Replaced 3 times to remove the air in the kettle, and then put the H in the kettle 2 Adjust it to 5.0 MPa, check the airtightness of the device and confirm that there is no leakage, react at a reaction temperature of 300 °C for 1.0 h, and take out the reaction product after cooling to room temperature for gas chromatography analysis. See Table 1 for the naphthalene and asphalt contents in the hydrogenation product measured by the internal standard method.

Embodiment 2

[0024] Except that the mass ratio of toluene / coal tar is 4 and the mass ratio of catalyst / coal tar is 0.08, the others are the same as in Example 1. The naphthalene content and asphalt content in the hydrogenation product measured by the internal standard method are shown in Table 1.

Embodiment 3

[0026] In addition to the H in the kettle 2 Adjusted to 3.0 MPa, the rest is the same as in Example 1. The naphthalene content and asphalt content in the hydrogenation product measured by the internal standard method are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com