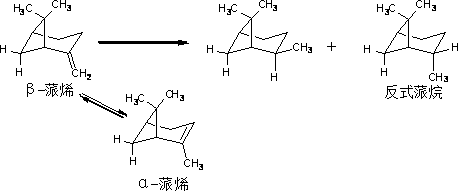

A kind of method for preparing pinane by catalytic hydrogenation of β-pinene

A technology for catalytic hydrogenation and pinene, which is applied in the chemical industry to achieve the effects of easy recovery, superior performance and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method for preparing pinane by catalytic hydrogenation of β-pinene described in this embodiment specifically comprises the following steps:

[0031] (1) Take a certain amount of β-pinene and put it in the reaction kettle, and then add the supported [Rh(COD)Cl] according to the mass of the catalyst at 5% of the mass of β-pinene 2 / C catalyst, sealed reactor;

[0032] (2) Use N at 0.3MPa 2 Replace the gas in the kettle 3 times, and then use H 2 Replace the gas in the kettle for 3 times under 0.3MPa, and check the air tightness;

[0033] (3) Open H 2 The inlet valve was used to adjust the reaction pressure to 1MPa, and the reaction was carried out at 80°C for 5h.

[0034] (4) After the reaction is over, stop heating and stirring, open the reaction kettle after pressure relief, and filter and separate the catalyst and reactants.

[0035] The reaction product was detected and analyzed by gas chromatography, the conversion rate of β-pinene was 99.76%, and the cis-tra...

Embodiment 2

[0041] The method for preparing pinane by catalytic hydrogenation of β-pinene described in this embodiment specifically comprises the following steps:

[0042] (1) Take a certain amount of β-pinene and put it in the reaction kettle, and then add the supported [Rh(COD)Cl] according to the mass of the catalyst at 3% of the mass of β-pinene 2 / C catalyst, sealed reactor;

[0043] (2) Use N at 0.1MPa 2 Replace the gas in the kettle 3 times, and then use H 2 Replace the gas in the kettle for 3 times under 0.1MPa, and check the air tightness;

[0044] (3) Open H 2 Inlet valve, adjust the reaction pressure to 3MPa, and react at 50°C for 3h.

[0045] (4) After the reaction is over, stop heating and stirring, open the reaction kettle after pressure relief, and filter and separate the catalyst and reactants.

[0046] The reaction product was detected and analyzed by gas chromatography, the conversion rate of β-pinene was 99.81%, and the cis-trans ratio of pinane was 7.64.

[0047]...

Embodiment 3

[0052] The method for preparing pinane by catalytic hydrogenation of β-pinene described in this embodiment specifically comprises the following steps:

[0053] (1) Take a certain amount of β-pinene and put it in the reactor, and then add the supported [Rh(COD)Cl] according to the mass of the catalyst at 4% of the mass of β-pinene 2 / C catalyst, sealed reactor;

[0054] (2) Use N at 0.3MPa 2 Replace the gas in the kettle 3 times, and then use H 2 Replace the gas in the kettle for 3 times under 0.3MPa, and check the air tightness;

[0055] (3) Open H 2 Inlet valve, adjust the reaction pressure to 4MPa, and react at 40°C for 4h.

[0056] (4) After the reaction is over, stop heating and stirring, open the reaction kettle after pressure relief, and filter and separate the catalyst and reactants.

[0057] The reaction product was detected and analyzed by gas chromatography, the conversion rate of β-pinene was 100%, and the cis-trans ratio of pinane was 8.04.

[0058] Loading t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com