Copper catalytic preparation method of cyclopentanone

A cyclopentanone, copper catalyzed technology is applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc. Source-rich, easy-to-manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

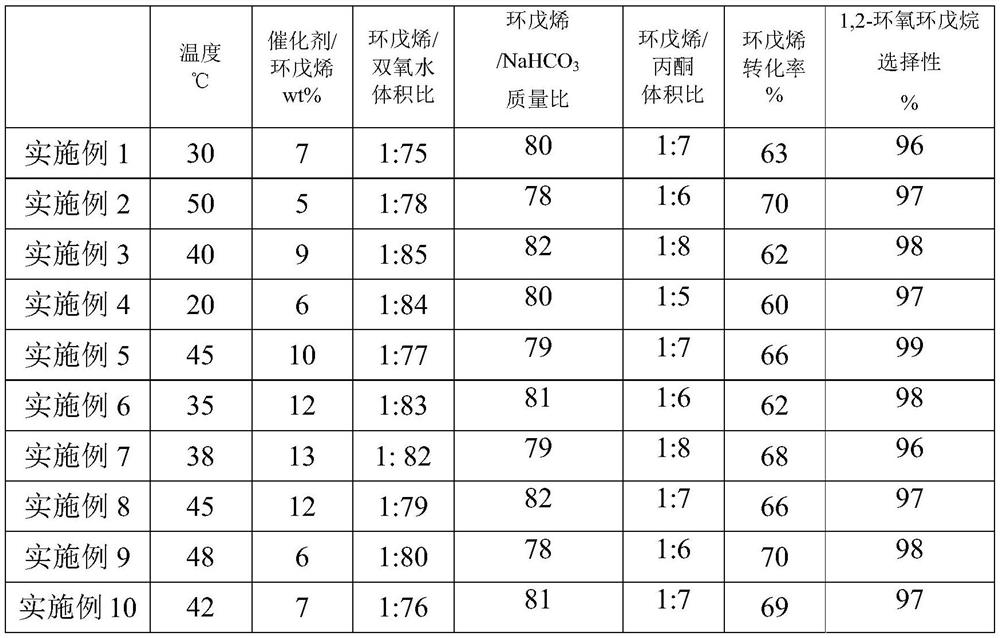

Embodiment 1~10

[0038] 1. Oxidation reaction

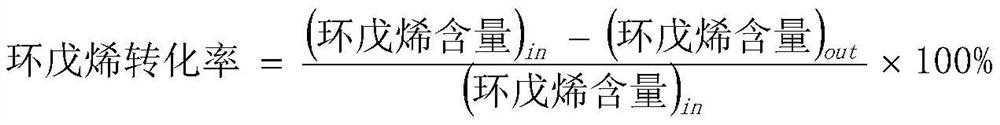

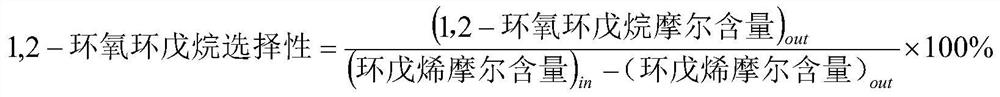

[0039] The conversion of cyclopentene and the selectivity of 1,2-epoxycyclopentane are calculated according to the following formula:

[0040]

[0041]

[0042] Among them, (cyclopentene content) in Indicates cyclopentene import molar content; (cyclopentene content) out Indicates the molar content of cyclopentene outlet; (1,2-epoxycyclopentane molar content) indicates the molar content of 1,2-epoxycyclopentane in the reaction liquid after oxidation reaction; (cyclopentene molar content) in represents Cyclopentene import molar content; (cyclopentene molar content) out means cyclopentene export molar content.

[0043] The reactor for the oxidation reaction is a tank reactor. Add cyclopentene and acetone to the reactor in proportion, and then put in the catalyst TS-1 molecular sieve catalyst in proportion. The catalyst is provided by Sinopec Shanghai Petrochemical Research Institute. The additive NaHCO 3 and hydrogen peroxide for an oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com