Elastic hydrophobic material and synthetic method as well as application thereof

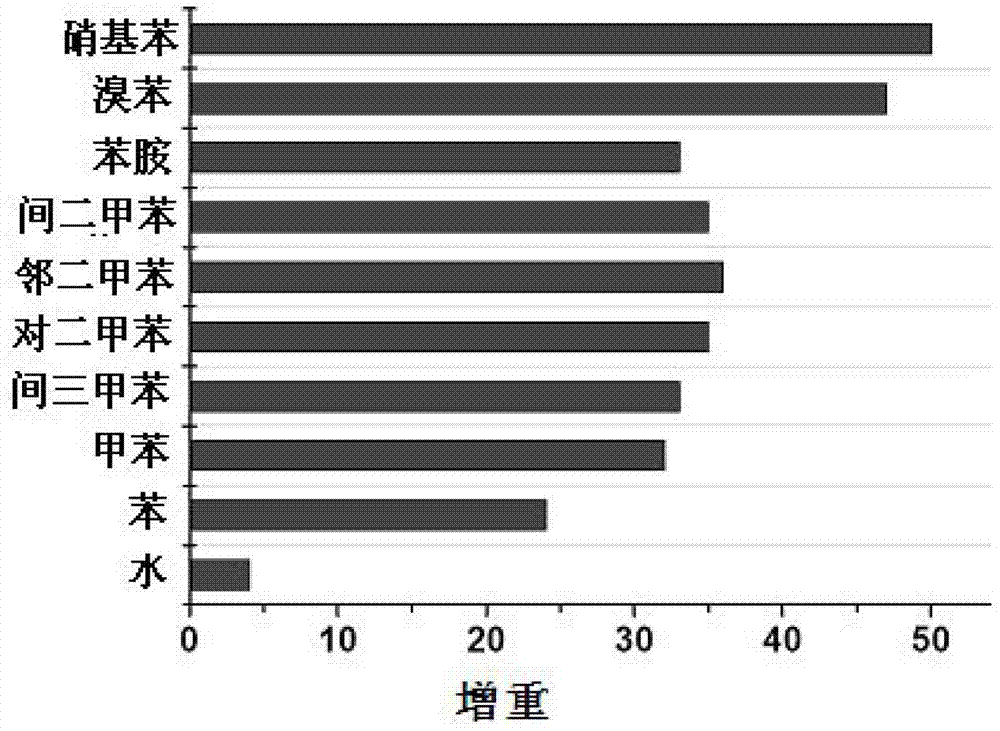

An elastic and hydrophobic adsorption technology, used in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of insufficient bonding between polymers and sponges, insoluble and insoluble, and difficult industrial applications, and achieve excellent separation. performance, large adsorption capacity, convenient regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Synthesis: 2 mmol of 1,4-diethynylbenzene, 2 mmol of 1,3,5-tribromobenzene, 100 mg of tetrakis(triphenylphosphine) palladium, 30 mg of cuprous iodide, commercially available sponge Cut into 10mm pieces (80mg), placed in a 100ml dry round bottom flask. Pass argon gas into the round bottom flask and exhaust the air for 20 minutes to form an anhydrous and oxygen-free environment. Then add 15ml of toluene and 15ml of triethylamine into the device with a syringe, stir vigorously under argon atmosphere, then raise the temperature to 80°C, and react for 6h.

[0044] 2. Filtration: wash the product with dichloromethane, acetone, deionized water, and methanol respectively, and vacuum-dry at 70°C for 3 hours to obtain an elastic hydrophobic material with a mass of 230mg. That is to say, 150 mg of polymers grew closely inside the 80 mg of sponge, which was difficult to remove.

Embodiment 2

[0046] 1. Synthesis: 3 mmol of 1,4-diethynylbenzene, 2 mmol of 2,4,6-tribromotoluene, 100 mg of tetrakis(triphenylphosphine) palladium, 30 mg of cuprous iodide, commercially available poly The ammonia fat sponge was cut into 5mm pieces (100mg), and placed in a 100ml dry round bottom flask. Pass argon gas into the round bottom flask and exhaust the air for 20 minutes to form an anhydrous and oxygen-free environment. Then add 30ml of toluene and 15ml of triethylamine into the device with a syringe, stir vigorously under argon atmosphere, then raise the temperature to 90°C, and react for 8h.

[0047] 2. Filtration: Wash the product with chloroform, acetone, deionized water, and ethanol respectively, and vacuum-dry it at 70°C for 3 hours to obtain an elastic hydrophobic material with a mass of 210mg. That is to say, 110 mg of the polymer is densely grown inside the 100 mg of sponge, which is difficult to remove.

Embodiment 3

[0049] 1. Synthesis: 2mmol of 1,3,5-triethynylbenzene, 2mmol of 2,4,6-tribromophenol, 30mg of tetrakis(triphenylphosphine)palladium, 10mg of cuprous iodide, melamine sponge Cut into 20mm pieces (100mg), placed in a 100ml dry round bottom flask. Nitrogen was passed into the round bottom flask to exhaust the air for 20 minutes to form an anhydrous and oxygen-free environment. Then add 50ml of toluene and 15ml of triethylamine into the device with a syringe, stir vigorously under argon atmosphere, then raise the temperature to 60°C, and react for 5h.

[0050] 2. Filtration: Wash the product with dichloromethane, acetone, deionized water, and ethanol, and vacuum-dry it at 70°C for 3 hours to obtain an elastic hydrophobic material with a mass of 260 mg. That is to say, 150 mg of the polymer is densely grown inside the 100 mg of sponge, which is difficult to remove.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com