Preparation method of piezoelectric ceramic surface electrode

A piezoelectric ceramic and surface electrode technology, which is applied in the field of piezoelectric ceramic surface electrode preparation, can solve the problems of high cost of gold electrodes, highly toxic cyanide, and easy corrosion of plated parts, and achieves good welding performance and low porosity. , the effect of strong weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. The solution used for nickel plating is as follows:

[0039]

[0040] 2. Prepare each solution according to the following method:

[0041] Coarse solution: Prepare mineral acid and distilled water in proportion.

[0042] Sensitizer: SnCl 2 2H 2 O, concentrated hydrochloric acid and distilled water are prepared in proportion, and the dissolution process is heated.

[0043] Activation solution: PdCl 2 It is formulated by dissolving in diluted hydrochloric acid, and heat-treated during the dissolution process.

[0044] Nickel plating solution: a. Dissolve the calculated and weighed various chemicals with appropriate amount of distilled water;

[0045] b. NaH 2 PO 2 ·H 2 O and NH 4 Cl solution was mixed to make B solution;

[0046] c. NiSO 4 ·7H 2 O, BSO additive (BSO additive is a commonly used additive for electroless plating, its main chemical component is saccharin, scientific name o-benzoylsulfonimide, primary brightener) and NaC 6 h 5 o 7 2H 2 Ea...

Embodiment 2

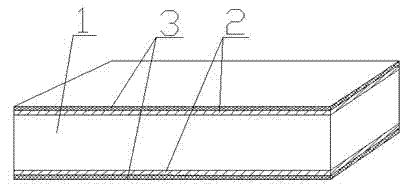

[0073] Prepare the nickel-gold composite electrode according to the method of Example 1, the difference is: the piezoelectric ceramic used is a PLN piezoelectric ceramic block, and the solution and process used for nickel plating are as follows:

[0074]

[0075]

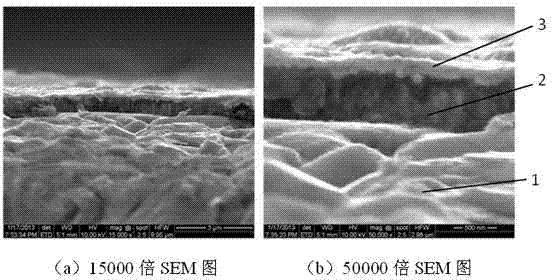

[0076] Prepare the required nickel plating solution and gold plating solution according to the method of Example 1, and carry out chemical gold plating on the surface of the PLN piezoelectric ceramic block with the nickel base layer plated. The obtained electrode has good gloss, low porosity, uniform and dense crystal grains, and is closely attached to the surface of the nickel layer, and the gold plating layer is relatively thin, with a thickness of 0.13 μm. The whole electrode is closely combined with the piezoelectric ceramic substrate, and the weldability and bonding force are good. The resistivity is low, the value is 1.054×10 -7 Ω·m, the corrosion potential is relatively positive, the value is -0.372V,...

Embodiment 3

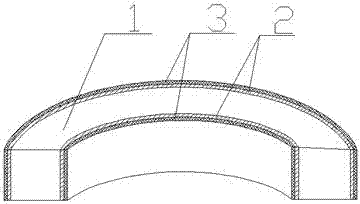

[0078] Prepare the nickel-gold composite electrode according to the method of Example 1, the difference is: the piezoelectric ceramic used is a PZT-5 piezoelectric ceramic ring, and the solution and process used for nickel plating are as follows:

[0079]

[0080]

[0081] The required nickel plating solution and gold plating solution were prepared according to the method in Example 1, and electroless gold plating was performed on the surface of the PZT-5 piezoelectric ceramic ring plated with the nickel base layer. The obtained electrode has good gloss, low porosity, uniform and dense crystal grains, and is closely attached to the surface of the nickel layer, and the gold plating layer is relatively thin, with a thickness of 0.13 μm. The whole electrode is closely combined with the piezoelectric ceramic substrate, and the weldability and bonding force are good. The resistivity is low, the value is 0.900×10 -8 Ω·m, the corrosion potential is relatively positive, the valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com