Cubic texture Ce1-sigmaGdsigmaO2 film on NiW alloy substrate and preparation method thereof

A cubic texture and alloy technology is applied in the field of cubic texture Ce1-σGdσO2 thin film and its preparation to achieve the effect of reducing the degree of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

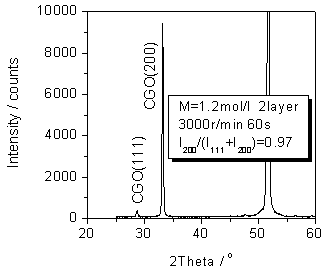

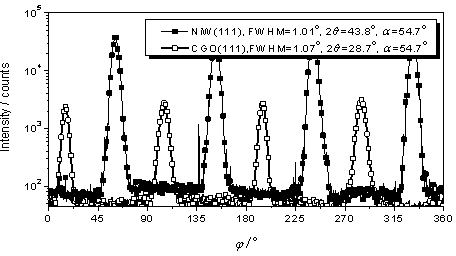

[0021] Cubic Texture Ce on a NiW Alloy Substrate 0.9 Gd 0.1 o 2 thin film, Ce grown on a cubic textured NiW alloy substrate 0.9 Gd 0.1 o 2 Thin film with a thickness of 200nm, with (200) preferred orientation and face-centered cubic crystal structure, with a texture form of {100}, and the NiW alloy is a Ni-5%W alloy containing 5%W by mass percentage .

[0022] Its preparation method is:

[0023] (1) with (CH 3 CO 2 ) 3 Ce(III) and GdN 3 o 9 As the starting material, according to the molar ratio Ce 3+ : Gd 3+ The ratio of =9:1 is to dissolve the raw material in propionic acid (C 2 h 5 COOH), adjust the solution Ce 3+ and Gd 3+ with a total concentration of 1.2 mol / l to give Ce 0.9 Gd 0.1 o 2 Precursor;

[0024] (2) will Ce 0.9 Gd 0.1 o 2 The precursor solution was spin-coated on the Ni-5%W alloy substrate with a homogenizer at a speed of 3000r / min for 60s, and then the spin-coated substrate was sent into the furnace tube. 2 The {100} texture Ce on t...

Embodiment 2

[0030] Cubic Texture Ce on a NiW Alloy Substrate 0.8 Gd 0.2 o 2 thin film, Ce grown on a cubic textured NiW alloy substrate 0.8 Gd 0.2 o 2 The film, with a thickness of 400nm, has a (200) preferred orientation and a face-centered cubic crystal structure, and the texture form is {100}. The NiW alloy is a Ni-5%W alloy containing 5%W by mass percentage.

[0031] Its preparation method is:

[0032] (1) with (CH 3 CO 2 ) 3 Ce(III) and GdN 3 o 9 As the starting material, according to the molar ratio Ce 3+ : Gd 3+ =4 : A ratio of 1 was dissolved in propionic acid (C 2 h 5 COOH), adjust the solution Ce 3+ and Gd 3+ The total concentration of 1.0mol / l, to obtain Ce 0.8 Gd 0.2 o 2 Precursor;

[0033] (2) will Ce 0.8 Gd 0.2 o 2 The precursor solution was spin-coated on the Ni-5%W alloy substrate with a homogenizer at a speed of 3500r / min for 30s, and then the spin-coated substrate was sent into the furnace tube, in 4% volume of H 2 and 96% volume of Ar atmosp...

Embodiment 3

[0036] A {100} Texture Ce on a Ni-5%W Substrate 0.86 Gd 0.14 o 2 The buffer layer is Ce grown on the cubic textured NiW alloy substrate 0.86 Gd 0.14 o 2 The film, with a thickness of 500nm, has a (200) preferred orientation and a face-centered cubic crystal structure, and the texture form is {100}. The NiW alloy is a Ni-5%W alloy containing 5%W by mass percentage.

[0037] Its preparation method is:

[0038] (1) with (CH 3 CO 2 ) 3 Ce(III) and GdN 3 o 9 As the starting material, according to the molar ratio Ce 3+ : Gd 3+ =6 : A ratio of 1 was dissolved in propionic acid (C 2 h 5 COOH), adjust the solution Ce 3+ and Gd 3+ with a total concentration of 1.1 mol / l to give Ce 0.86 Gd 0.14 o 2 Precursor;

[0039] (2) will Ce 0.86 Gd 0.14 o 2 The precursor solution was spin-coated on the Ni-5%W alloy substrate with a homogenizer at a speed of 4000r / min for 50s, and then the spin-coated substrate was sent into the furnace tube, in 3% volume of H 2 and 97% v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com