Synthesis method of 8-hydroxyl ethyl caprylate

A technology of ethyl hydroxyoctanoate and a synthetic method, which is applied in the field of synthesis of pharmaceutical intermediates, can solve problems such as high raw material prices, complex processes, and long reaction routes, and achieve the advantages of industrial production, simplified process steps, and convenient source of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

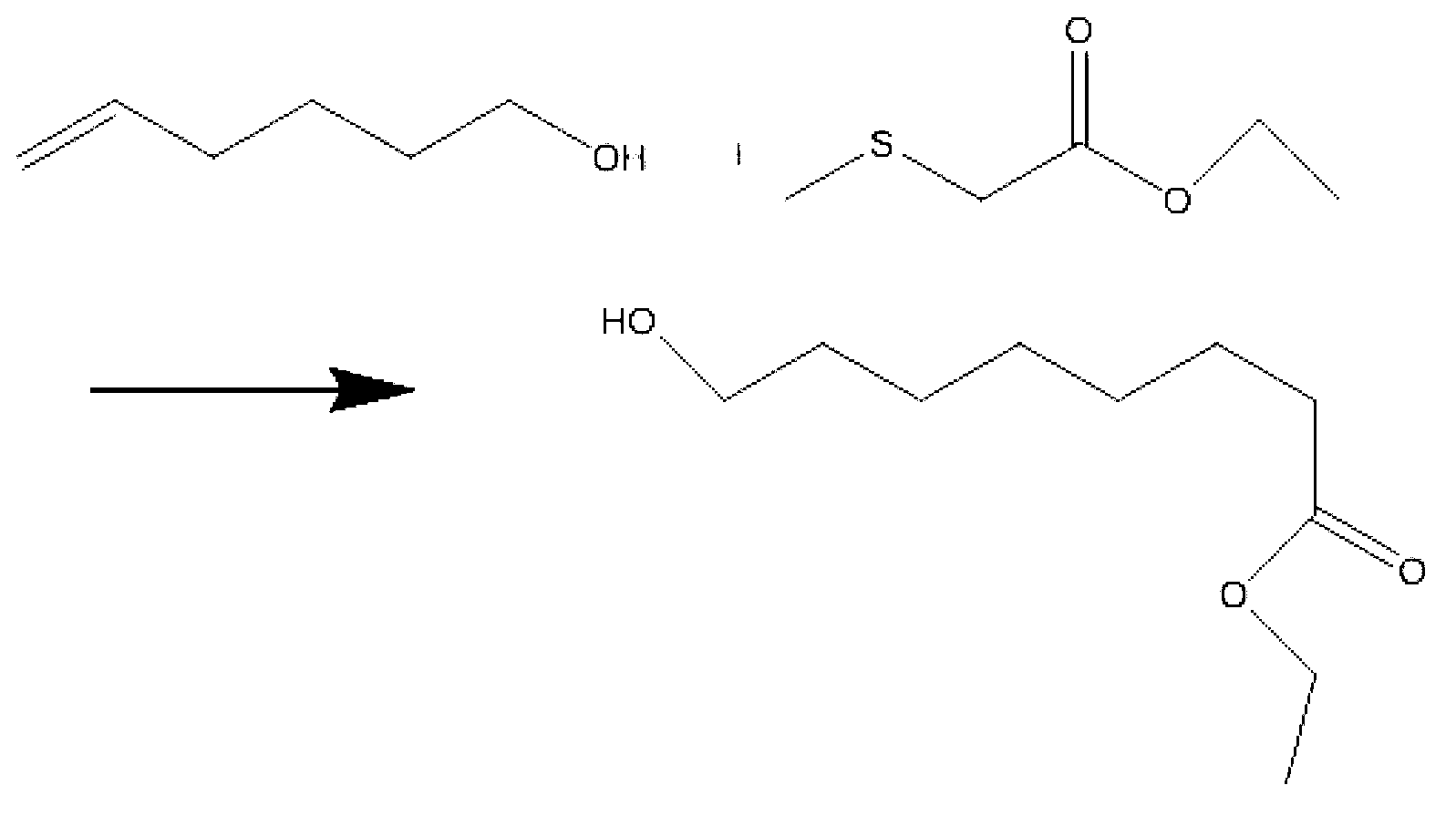

[0031] The synthetic method of 8-hydroxy octanoic acid ethyl ester of the present invention, as Figure 4 as shown, Figure 4 It is a schematic flow sheet of the synthetic method of 8-hydroxyoctanoic acid ethyl ester of the present invention, comprising:

[0032] Step 101, dissolving 6-bromohexanol and diethyl malonate in an azeotropic organic solvent and performing a heating reaction under alkali catalysis to generate an intermediate, which is 2-(6-hydroxyhexyl) Diethyl malonate, wherein the molar ratio of 6-bromohexanol, diethyl malonate and base is 1:0.95~1.05:1.37~2.73;

[0033] Step 102, dissolving the intermediate in a polar aprotic solvent and water under the catalysis of sodium halide for heating reaction to generate ethyl 8-hydroxyoctanoate, wherein the molar ratio of the intermediate to sodium halide is 1 : 1~3.

[0034] In the embodiment of the present invention, first, 6-bromohexanol and diethyl malonate are reacted under alkali catalysis, and hydrogen bromide i...

Embodiment 1

[0047] Step 1, add 6-bromohexanol 132.5g, diethyl malonate 119g in the four-necked flask of 1000ml, alkali selects potassium carbonate 195g, wherein, 6-bromohexanol, diethyl malonate and potassium carbonate The molar ratio is 1:1.016:1.93. The azeotropic organic solvent is 120ml of N,N-dimethylformamide (DMF) and 250ml of cyclohexane, and the temperature is raised to 80°C for reflux reaction, and the reaction is determined by gas chromatography. After completion, it was lowered to room temperature, and the filter cake and filtrate were obtained by suction filtration. The filtrate was concentrated to dryness, diluted with 200ml ethyl acetate, washed with water, and concentrated to obtain 175g of yellow oily liquid, i.e. intermediate 2-(6-hydroxyhexyl) Diethyl malonate, the molar yield is 90%;

[0048] Step 2. Dissolve the product obtained in the previous step in 300ml of dimethyl sulfoxide, add 46g of sodium chloride and 23g of water, raise the temperature to 145°C, keep the te...

Embodiment 2

[0051] Step 1. Add 132.5 g of 6-bromohexanol, 119 g of diethyl malonate, and 212 g of sodium carbonate in a 1000 ml four-necked flask, wherein 6-bromohexanol, diethyl malonate and sodium carbonate The molar ratio is 1:1.016:2.73, 150ml of N,N-diethylformamide and 250ml of n-hexane are selected as the azeotropic organic solvent, and the temperature is raised to 150°C for reflux. After the reaction is judged by gas chromatography, it is cooled to room temperature. Suction filtration obtains filter cake and filtrate, and filtrate is concentrated dry, is diluted with 200ml ethyl acetate, then washes with water, concentrates, obtains 167g yellow oily liquid, i.e. intermediate 2-(6-hydroxyhexyl) diethyl malonate, Molar yield is 86%;

[0052] Step 2. Dissolve the product obtained in the previous step in 250ml of dimethyl sulfoxide, add 78g of sodium bromide and 30g of water, raise the temperature to 100°C, keep the temperature for 8 hours, then cool down to 20°C, and use 200ml of ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com