Preparation method of Eu2O3-Dy2O3-codoped zinc-silicon-system microcrystalline glass

A eu2o3-dy2o3, glass-ceramic technology, applied in the field of LED luminescent materials, can solve the problems of easy aging, poor luminous stability, etc., and achieve the effects of pure luminosity, stable physicochemical properties, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 7.40 g of zinc oxide, 11.84 g of boric acid, 20.35 g of silicon dioxide, 3.7 g of aluminum oxide, 1.85 g of sodium carbonate, 1.85 g of titanium dioxide, and 1.10 g of europium oxide.

[0034] Grind the above raw materials with a mortar to obtain a uniform powder. Put the ground raw material into a corundum crucible, put it in a resistance furnace, and melt it at a temperature of 1500°C, then pour the molten raw material into glass, then put it into a muffle furnace, and nucleate it at 600°C 2h, crystallized at 770°C for 6h, and finally obtained the luminescent glass-ceramics under this composition.

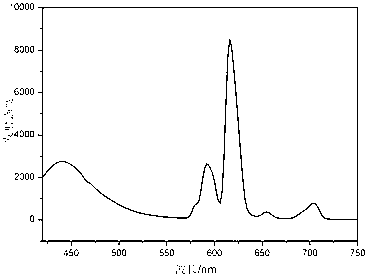

[0035] like figure 1 As shown, it presents orange-red light under the excitation of ultraviolet light at 391nm, and the glass sample has five emission bands: at 441nm, it belongs to Eu 2+ ion 4f 6 5d → 4f 7 transition, and a relative strength of 2695. Located at 592nm attributed to Eu 3+ Ionic 5 D.0 → 7 f 1 transition, and a relative strength of 2545. Locat...

Embodiment 2

[0037] Weigh 9.25g of zinc oxide, 12.95g of boric acid, 13.32g of silicon dioxide, 5.55g of aluminum oxide, 2.59g of sodium carbonate, 0.37g of titanium dioxide, and 1.20g of dysprosium trioxide.

[0038] Grind the above raw materials with a mortar to obtain a uniform powder. Put the ground raw material into a corundum crucible, put it in a resistance furnace, and melt it at a temperature of 1500°C, then pour the molten raw material into glass, then put it into a muffle furnace, and nucleate it at 600°C 2h, crystallized at 770°C for 6h, and finally obtained the luminescent glass-ceramics under this composition.

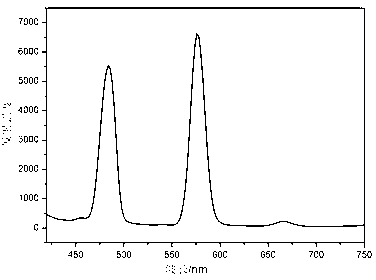

[0039] like figure 2 As shown, it presents yellow light under the excitation of 396nm ultraviolet light, and the glass sample mainly has two emission bands: the one at 484nm belongs to Dy 3+ Ionic 4 f 9 / 2 → 6 h 15 / 2 transition, and the relative intensity is 5544, which is assigned to Dy at 576nm 3+ Ionic 4 f 9 / 2 → 6 h 13 / 2 transition with a relative streng...

Embodiment 3

[0041] Weigh 11.1 g of zinc oxide, 11.1 g of boric acid, 17.02 g of silicon dioxide, 1.85 g of aluminum oxide, 3.7 g of sodium carbonate, 1.11 g of titanium dioxide, 0.7 g of dysprosium trioxide, and 0.6 g of dieuropium trioxide.

[0042] Grind the above raw materials with a mortar to obtain a uniform powder. Put the ground raw material into a corundum crucible, put it in a resistance furnace, and melt it at a temperature of 1500°C, then pour the molten raw material into glass, then put it into a muffle furnace, and nucleate it at 600°C 2h, crystallized at 770°C for 6h, and finally obtained the luminescent glass-ceramics under this composition.

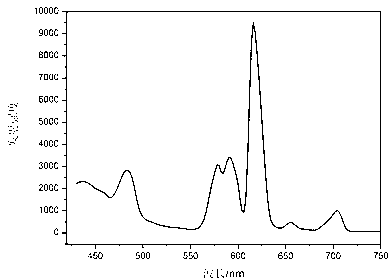

[0043] like image 3 As shown, it presents purple light under the excitation of ultraviolet light at 393nm, and the glass sample has seven emission bands: at 436nm, it belongs to Eu 2+ ion 4f 6 5d → 4f 7 The blue-green light of the transition, with a relative intensity of 2325, belongs to Dy at 483nm 3+ Ionic 4 f 9 / 2 → 6 h 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com