A method for reducing emissions of nitrogen oxide tail gas

A nitrogen oxides and tail gas technology, applied in nitrogen oxides/oxyacids, chemical instruments and methods, separation methods, etc., can solve the problems of increasing reaction rate, harsh adsorption environment conditions, and regeneration of adsorbents, so as to reduce environmental pollution. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

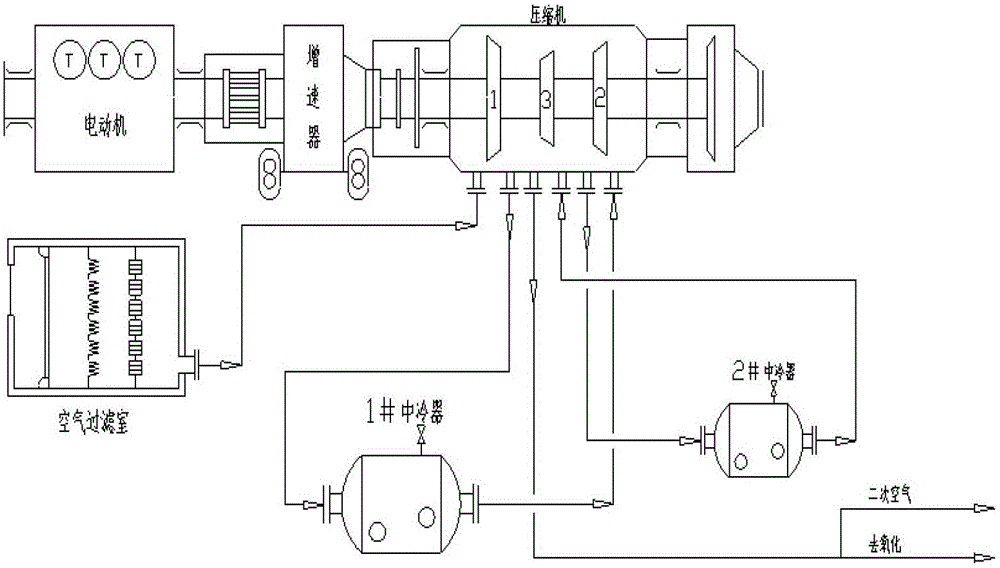

Image

Examples

Embodiment )

[0023] Wuhua Company's ammonium nitrate series products are 300,000 tons per year. The nitric acid plant generates nitrogen oxide gas during the production process, commonly known as laughing gas. Under normal production conditions, it cannot be converted into useful nitrogen dioxide, nor can it Absorbed by water, but discharged directly into the atmosphere. Nitrogen oxides are one of the most powerful greenhouse gases that cause climate change. The potential value of the greenhouse effect is 310 times that of carbon dioxide. The damage to the ozone layer is more serious than Freon. It can persist in the atmosphere for 150 to 170 years. Once formed, it is not easy to disappear. . The contribution rate to global warming is 6%, and the concentration in the atmosphere has increased rapidly in recent years. In order to reduce greenhouse gas emissions, implement the "12th Five-Year Plan for Industrial Clean Production", accelerate the application and promotion of advanced clean pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com