Method and equipment for removing high-density tobacco stem in microwave expansion tobacco stem

A technology of microwave expansion and expansion of tobacco stems, which is applied in tobacco, tobacco processing, application, etc., can solve problems such as uneven burning speed, inability to remove cut stems, and material size reduction, and achieve the effect of reducing investment in production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0054] Example 3 :like image 3 As shown, the tobacco stems are expanded by microwaves, the volume increases by 200-350%, the moisture reaches 3-5%, the temperature is 75-90°C, it is cooled and shaped, stored and aged for 7-60 days, and then rehydrated to make the microwave-expanded tobacco The moisture content of the stalk reaches 18-20%, and the high-density tobacco stalks are removed by the wind separator, and then the tobacco stalks are sliced, the slice thickness is 0.8mm, the stalks are shredded, and the width of the stalks is 0.2mm, and the stalks are dried to a moisture content of 13-14%. Obtain finished stem shreds.

Embodiment 4

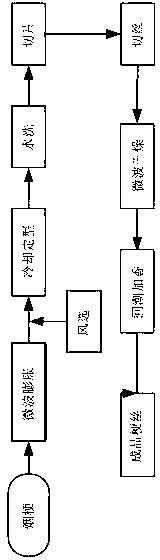

[0055] Example 4: like Figure 4 As shown, the tobacco stems are expanded by microwave, the volume increases by 200-350%, the moisture reaches 3-5%, and the temperature is 75-90°C. The produced tobacco stems with low expansion rate and high density are separated, and the tobacco stems with low density and high expansion rate are increased to 20-25% by a damper, and then stored for 1-3 hours and fed quantitatively. , Warming and humidifying to a moisture content of 25-28% and a temperature of 55-70°C, cut into stalks with a thickness of 0.3mm, temporarily store the stalks, row the stalks, cut the stalks into shredded stalks with a width of 0.9mm, and feed quantitatively , feeding cut stems, storing cut stems for 1-6 hours, quantitative feeding, drying, and flavoring cut stems to obtain finished cut stems.

Embodiment 5

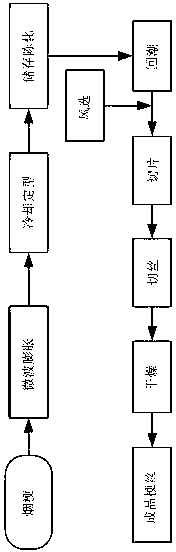

[0056] Example 5 :like Figure 5 As shown, the tobacco stems are heated and humidified to a moisture content of 12-15% and a temperature of 65-70°C, and then expanded by microwaves, the volume increases by 200-350%, the moisture reaches 3-5%, and the temperature is 75-90°C. The warehouse-type air separation equipment separates the tobacco stems with low expansion rate and high density caused by deterioration, high moisture, and uneven microwave irradiation. Increase to 20-25%, store the stems for 1-6 hours, straighten the stems, cut them into slices with a thickness of 0.2mm, feed the slices, store the slices for 1-4 hours, cut the slices into shredded stems with a width of 0.9mm, The shredded stems are shaped and dried, and the shredded stems are flavored to obtain the finished microwave-expanded shredded stems.

[0057] The shredded stems or granular stems obtained through the above five examples can be blended into shredded tobacco according to the formula ratio, and fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com