Peanut shell activated carbon for removing toxins in peanut oil and preparation method thereof

A peanut shell and activated carbon technology, applied in chemical instruments and methods, non-metallic elements, inorganic chemistry, etc., can solve the problems of environmental pollution and low added value, achieve simple operation process, reduce peroxide content, and improve product safety quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

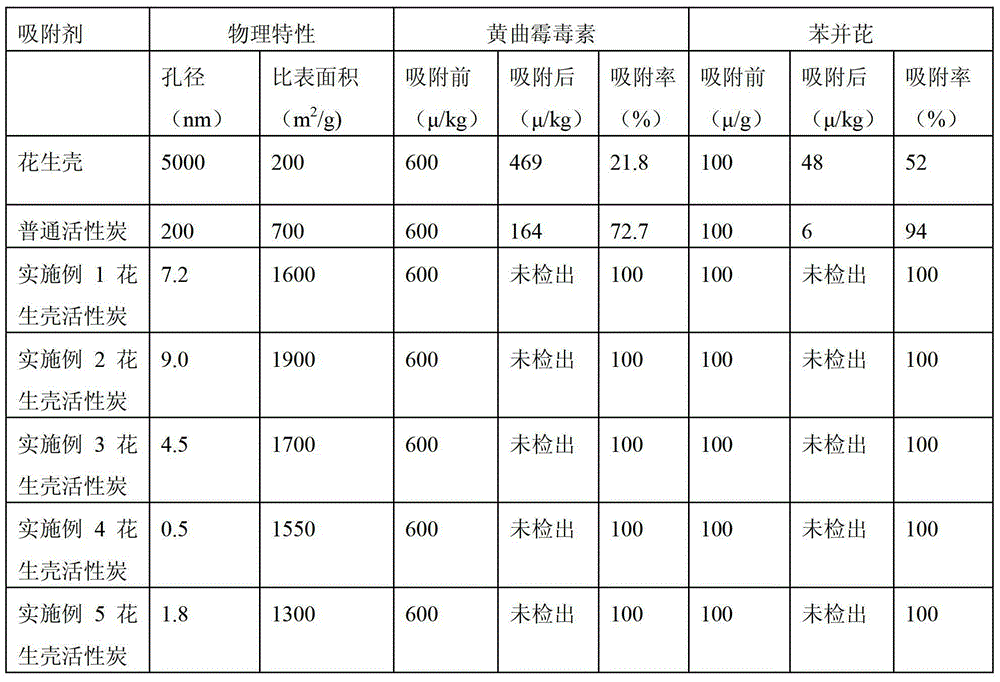

Image

Examples

Embodiment 1

[0029] (1) Pretreatment: Put the cleaned peanut shells in a 180°C flowing steam environment for 2 hours, crush them through a 2mm aperture sieve, add water to mix, adjust the water content to 4%, and store in a closed container at room temperature for 72 hours.

[0030] (2) Extrusion: Use a pelletizer to press peanut shell particles on a flat plate at 100°C into cylindrical pellets with a diameter of 6mm and a length of 12mm.

[0031] (3) Carbonization: Carbonization is carried out in a retort. The peanut shell cylinder is energized and heated to 450°C at a rate of 2°C / min, then cooled to room temperature under closed conditions, crushed and sieved, and the particle diameter is controlled to 1mm.

[0032] (4) Activation: Put the carbonized particles in a retort, add a steam superheating coil to the heating furnace, heat it to 840°C at a rate of 20°C per minute, store it in a sealed state, and continuously pass in isothermal superheated steam and seal it Save for 90 minutes, and ensur...

Embodiment 2

[0034] (1) Raw material pretreatment: Put the cleaned peanut shells in a flowing steam environment at 178℃ for 2.2h, crush them through a 2mm aperture sieve, add water to mix, adjust the water content to 6%, and store at room temperature for 78h in a closed container .

[0035] (2) Extrusion: Use a pelletizer to press peanut shell particles on a flat plate at 100°C into cylindrical pellets with a diameter of 6mm and a length of 18mm.

[0036] (3) Carbonization: Carbonization is carried out in a retort. The peanut shell cylinder is energized and heated to 500°C at a rate of 2°C / min, then cooled to room temperature under closed conditions, crushed and sieved, and the particle diameter is controlled to 3mm.

[0037] (4) Activation: Put the carbonized particles in a retort, add a steam superheating coil into the heating furnace, heat it to 850°C at a rate of 20°C per minute, continue to pass in isothermal superheated steam and keep it sealed for 100 minutes. And ensure that the mass rat...

Embodiment 3

[0039] (1) Raw material pretreatment: Put the cleaned peanut shells in a flowing steam environment at 175°C for 2.5 hours, crush them through a 2mm aperture sieve, add water to mix, adjust the moisture content to 8%, and store in a closed container at room temperature for 80 hours .

[0040] (2) Extrusion molding: The peanut shell particles are pressed on a 95°C flat plate with a pelletizer to form cylindrical particles with a diameter of 6mm and a length of 20mm.

[0041] (3) Carbonization: Carbonization is carried out in a retort. The peanut shell cylinder is energized and heated to 600°C at a rate of 2°C / min, then cooled to room temperature under closed conditions, crushed and sieved, and the particle diameter is controlled at 2.5mm .

[0042] (4) Activation: Put the carbonized particles in a retort, add a steam superheating coil into the heating furnace, and heat to 860°C at a rate of 21°C per minute. Continuously pass in isothermal superheated steam and seal for 80min. And ens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com