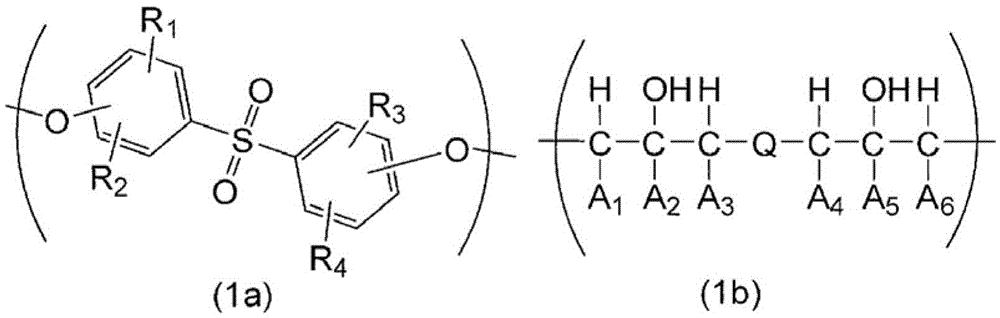

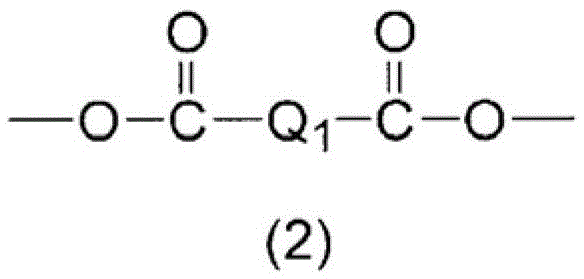

Composition for forming resist underlayer film and method for forming resist pattern using same

A technology of resist lower layer and composition, which is applied in the direction of photosensitive materials, coatings, and pattern surface photolithography for optomechanical equipment, and can solve the problems of no enlightenment and no record of binary polymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] The weight average molecular weights shown in the following synthesis examples 1 to 3 are based on the measurement results of gel permeation chromatography (hereinafter, abbreviated as GPC in this specification). For the measurement, a GPC apparatus manufactured by Tosoh Corporation was used, and the measurement conditions are as follows.

[0071] GPC column: Shodex〔registered trademark〕Asahipak〔registered trademark〕(Showa Denko Co., Ltd.)

[0072] Column temperature: 40°C

[0073] Solvent: N,N-Dimethylformamide (DMF)

[0074] Flow rate: 0.6ml / min

[0075] Standard sample: Polystyrene (Tosoh Corporation)

[0076] Detector: RI

[0077]

[0078] 10.00 g of diglycidyl terephthalate (manufactured by Nagase Chemtex Co., Ltd., trade name: Denakor [registered trademark] EX711), 4.38 g of bisphenol S, 2.68 g of 2,4-dihydroxybenzoic acid, and Ethyl triphenyl bromide After dissolving 0.65 g in 70.90 g of propylene glycol monomethyl ether, it was made to react at 130 degr...

Embodiment 2

[0090] Into 10 g of a solution containing 2 g of the polymer obtained in Synthesis Example 2 above, 0.5 g of tetramethoxymethyl glycoluril (manufactured by Japan Cytech Industries Co., Ltd., trade name: Powerlink [registered trademark] 1174) and p-toluenesulfon were mixed. acid pyridinium 0.05 g was dissolved in 35.4 g of propylene glycol monomethyl ether and 18.6 g of ethyl lactate to prepare a solution. Then, filtration was performed using a polyethylene microfilter with a pore diameter of 0.10 μm, and further, a polyethylene microfilter with a pore diameter of 0.05 μm was used to prepare a composition for forming a resist underlayer film.

Embodiment 3

[0092] In 10 g of a solution containing 2 g of the polymer obtained in Synthesis Example 3 above, 0.5 g of tetramethoxymethyl glycoluril (manufactured by Japan Cytech Industries Co., Ltd., trade name: Powerlink [registered trademark] 1174) and p-toluenesulfon were mixed. acid pyridinium 0.05 g was dissolved in 35.4 g of propylene glycol monomethyl ether and 18.6 g of ethyl lactate to prepare a solution. Then, filtration was performed using a polyethylene microfilter with a pore diameter of 0.10 μm, and further, a polyethylene microfilter with a pore diameter of 0.05 μm was used to prepare a composition for forming a resist underlayer film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com