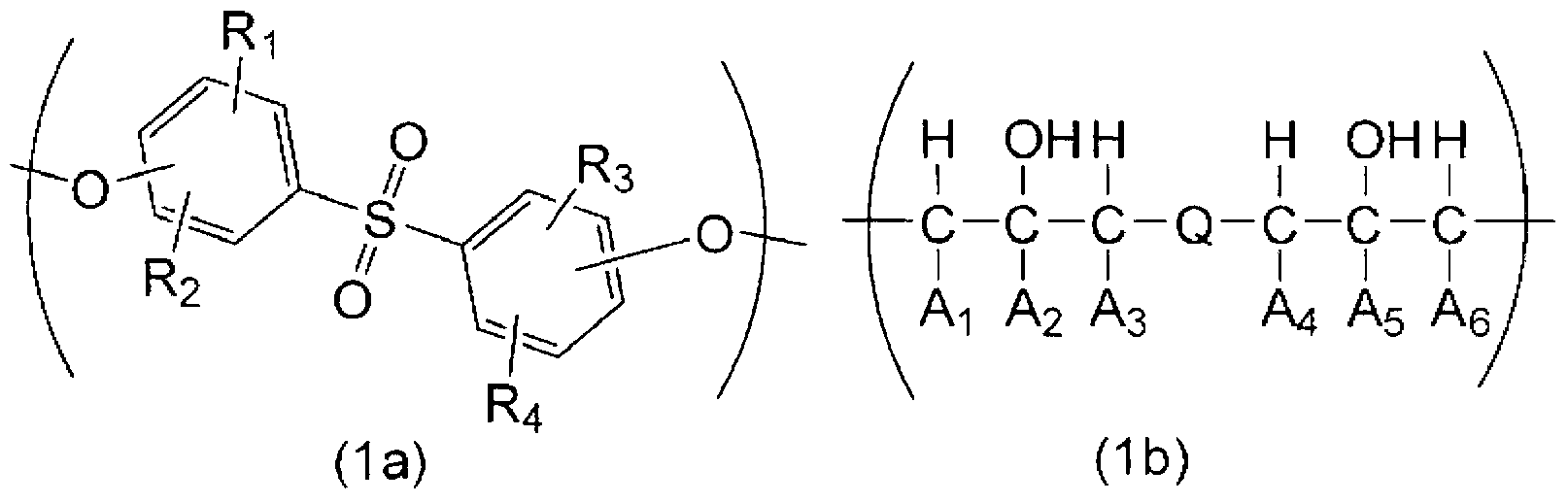

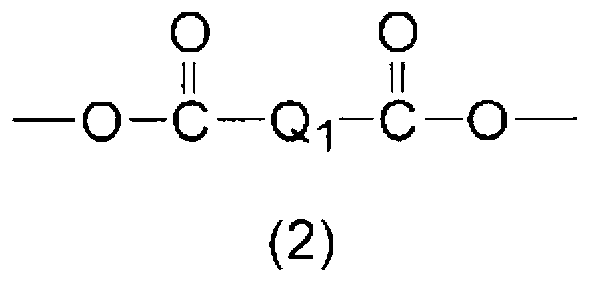

Resist underlayer film forming composition, and method for forming resist pattern using same

A technology of resist lower layer and composition, which is applied to photosensitive materials, coatings, and photoplate-making processes of patterned surfaces for optomechanical equipment, and can solve the problems of binary polymers that have no record and no inspiration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] The weight average molecular weights shown in the following synthesis examples 1 to 3 are based on the measurement results of gel permeation chromatography (hereinafter, abbreviated as GPC in this specification). For the measurement, a GPC apparatus manufactured by Tosoh Corporation was used, and the measurement conditions are as follows.

[0071] GPC column: Shodex〔registered trademark〕Asahipak〔registered trademark〕(Showa Denko Co., Ltd.)

[0072] Column temperature: 40°C

[0073] Solvent: N,N-Dimethylformamide (DMF)

[0074] Flow rate: 0.6ml / min

[0075] Standard sample: Polystyrene (Tosoh Corporation)

[0076] Detector: RI

[0077]

[0078] 10.00 g of diglycidyl terephthalate (manufactured by Nagase Chemtex Co., Ltd., trade name: Denakor [registered trademark] EX711), 4.38 g of bisphenol S, 2.68 g of 2,4-dihydroxybenzoic acid, and Ethyl triphenyl bromide After dissolving 0.65 g in 70.90 g of propylene glycol monomethyl ether, it was made to react at 130 degr...

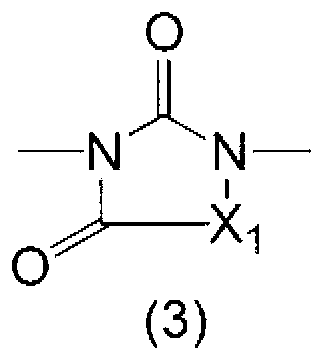

Embodiment 2

[0090] Into 10 g of a solution containing 2 g of the polymer obtained in Synthesis Example 2 above, 0.5 g of tetramethoxymethyl glycoluril (manufactured by Japan Cytech Industries Co., Ltd., trade name: Powerlink [registered trademark] 1174) and p-toluenesulfon were mixed. acid pyridinium 0.05 g was dissolved in 35.4 g of propylene glycol monomethyl ether and 18.6 g of ethyl lactate to prepare a solution. Then, filtration was performed using a polyethylene microfilter with a pore diameter of 0.10 μm, and further, a polyethylene microfilter with a pore diameter of 0.05 μm was used to prepare a composition for forming a resist underlayer film.

Embodiment 3

[0092] In 10 g of a solution containing 2 g of the polymer obtained in Synthesis Example 3 above, 0.5 g of tetramethoxymethyl glycoluril (manufactured by Japan Cytech Industries Co., Ltd., trade name: Powerlink [registered trademark] 1174) and p-toluenesulfon were mixed. acid pyridinium 0.05 g was dissolved in 35.4 g of propylene glycol monomethyl ether and 18.6 g of ethyl lactate to prepare a solution. Then, filtration was performed using a polyethylene microfilter with a pore diameter of 0.10 μm, and further, a polyethylene microfilter with a pore diameter of 0.05 μm was used to prepare a composition for forming a resist underlayer film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com