Resist underlayer film formation composition having disulfide structure

A resist lower layer, resist film technology, applied in coating, photoengraving process coating equipment, pattern surface photoengraving process and other directions, can solve the problems of resist pattern collapse, processing, etc., achieve dry The effect of high etching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0144] Hereinafter, the content of the present invention will be described more specifically by giving Examples and the like, but the present invention is not limited to the following aspects.

[0145] The apparatus used for the measurement of the weight average molecular weight of the polymer obtained in the synthesis example is shown below.

[0146] Device: HLC-8320GPC manufactured by Tosoh Corporation

[0147] GPC column: Shodex〔registered trademark〕Asahipak〔registered trademark〕(Showa Denko Co., Ltd.)

[0148] Column temperature: 40°C

[0149] Flow rate: 0.6mL / min

[0150] Eluent: N,N-dimethylformamide (DMF)

[0151] Standard sample: Polystyrene (Tosoh Corporation)

[0152]

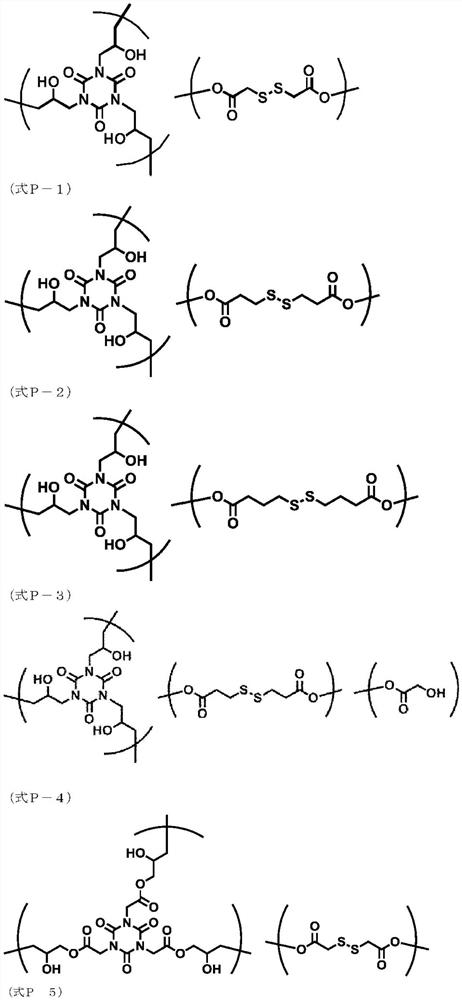

[0153] 4.00 g of 1,3,5-tris(2,3-epoxypropyl)isocyanuric acid (product name: TEPIC-SS, manufactured by Nissan Chemical Co., Ltd.), 7.42 g of dithioglycolic acid, and triphenyl bromide 0.38 g and 47.19 g of propylene glycol monomethyl ether were put into a reaction flask, and heated and stirred a...

Embodiment 2

[0157] After adding 4.00 g of 1,3,5-tris(2,3-epoxypropyl)isocyanuric acid (product name: TEPIC-SS, manufactured by Nissan Chemical Co., Ltd.), 3,3'-dithio Dipropionic acid 8.56g, ethyl triphenyl bromide 0.38 g and 51.76 g of propylene glycol monomethyl ether were heated and stirred at 100° C. for 21 hours in a nitrogen atmosphere in a reaction flask to obtain a solution of a transparent reaction product. The reaction product corresponding to the formula (C-2) was obtained as a solution, and the weight average molecular weight Mw in terms of polystyrene measured by GPC was 5,700. In addition, a:b=100:300 (molar ratio) in formula (C-2).

[0158] Added 7.09 g of a solution (16.4% by weight of solid content) corresponding to the reaction product of the formula (C-2), and pyridinium trifluoromethanesulfonate as a crosslinking acid catalyst Salt 0.03g, surfactant (manufactured by DIC Co., Ltd., product name: Megafac [trade name] R-40, fluorine-based surfactant) 0.001g, propylene...

Embodiment 3

[0161] 4.00 g of 1,3,5-tris(2,3-epoxypropyl)isocyanuric acid (product name: TEPIC-SS, manufactured by Nissan Chemical Co., Ltd.), 3,3'-dithiodipropylene Acid 4.40g, glycolic acid 1.59g, ethyl triphenyl bromide 0.39 g and 41.51 g of propylene glycol monomethyl ether were put into the reaction flask, and heated and stirred at 100° C. for 15 hours in a nitrogen atmosphere to obtain a solution of a transparent reaction product. A reaction product corresponding to the formula (C-3) was obtained, and the weight average molecular weight Mw in terms of polystyrene measured by GPC was 1400. In addition, in formula (C-3), a:b:c=100:150:150 (molar ratio).

[0162] Added 6.41 g of a solution (18.2% by weight of solid content) corresponding to the reaction product of the formula (C-3), and pyridinium trifluoromethanesulfonate as a crosslinking acid catalyst Salt 0.03g, surfactant (manufactured by DIC Co., Ltd., product name: Megafac [trade name] R-40, fluorine-based surfactant) 0.001g,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com