Preparation method of three-dimensional graphene or composite system thereof

A graphene, three-dimensional technology, which is applied in the field of preparation of high-quality three-dimensional graphene or its composite system, can solve the problems of limited macro-scale preparation and low graphene bulk density, and achieve the effect of mass preparation and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Furthermore, as one of the feasible specific embodiments, the preparation method of the present invention may include:

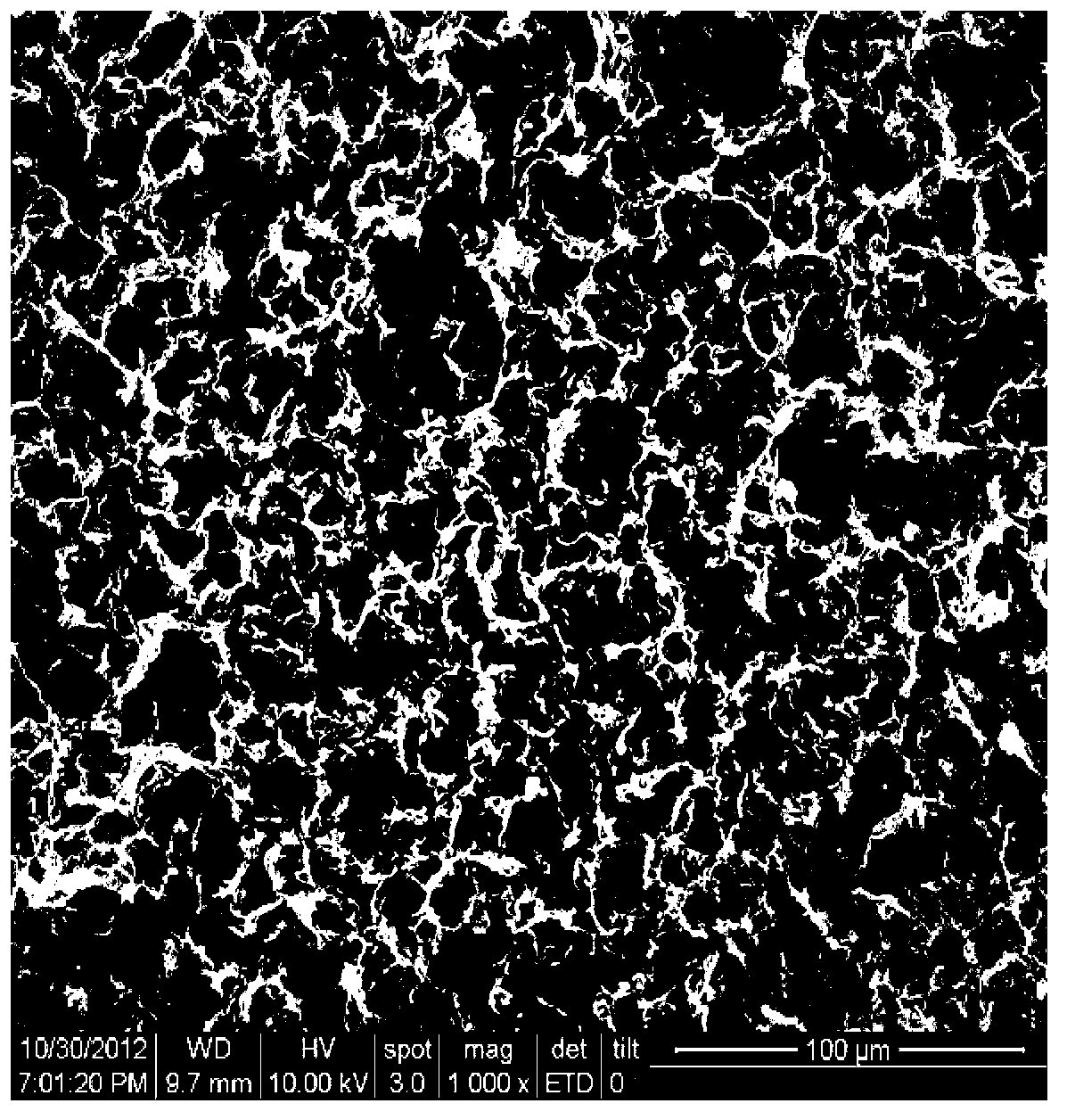

[0031] Take transition metal element, oxide, salt or its hydrate as raw material (ie, precursor), heat and dry the transition salt hydrate or microwave heating to remove crystal water to obtain anhydrous transition metal salt or fill the above precursors In the macroporous foam metal template, reduction is performed in a high temperature environment and an appropriate atmosphere environment, and finally a three-dimensional crosslinked metal catalyst template is obtained. Then, high-quality three-dimensional graphene powder is prepared by chemical vapor deposition, which forms a composite system with metal particles, metal oxides and polymers.

[0032] The three-dimensional graphene obtained by the invention has the characteristics of good electrical conductivity, large specific surface area and high density. The three-dimensional graphene and its composite...

Embodiment 1

[0035] Example 1: Add 5 g of copper powder to polymethyl methacrylate (PMMA: 4%), put the sample in a quartz tube, and ventilate argon for 15 minutes. The tube furnace was raised to 900°C, and the atmosphere environment was: hydrogen: 200 sccm, argon: 100 sccm; the pressure was maintained at: 10 torr. After the growth is complete, argon gas is applied to 200 sccm until the quartz tube cools. Put the grown sample into 1M FeCl 3 / 0.1M HCl solution for etching to obtain three-dimensional graphene.

Embodiment 2

[0036] Example 2: Add 5 g of nickel powder to polymethyl methacrylate (PMMA: 4%), put the sample in a quartz tube, and ventilate argon for 15 minutes. The tube furnace was raised to 900°C, and the atmosphere environment was: hydrogen: 200 sccm, argon: 100 sccm; the pressure was maintained at: 10 torr. After the growth is complete, let argon gas flow 200sccm until the quartz tube cools. Put the grown sample into 1M FeCl 3 / 0.1M HCl solution for etching to obtain three-dimensional graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com