A kind of urease nanoreactor and preparation method thereof

A nano-reactor and urease technology, which is applied in the field of bionic materials, can solve the problems of difficulty in encapsulating active enzymes in nano-reactors, complicated preparation process, and enzyme leakage, and achieves rapid shell cross-linking reaction, prolonged cycle time, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

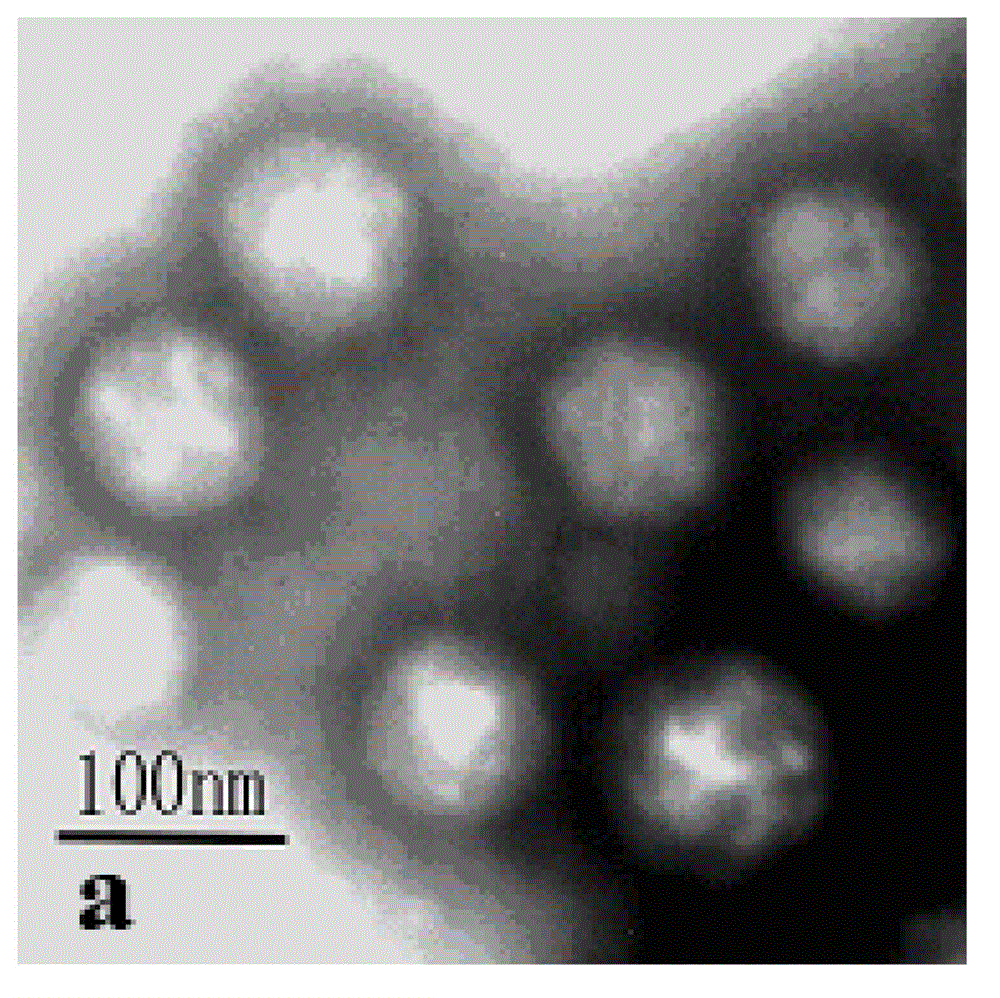

[0038] Embodiment 1: urease nanoreactor

[0039] The urease nanoreactor is effectively composed of carboxymethyl chitosan derivatives and urease that are cross-linked by ultraviolet light, and the urease nanoreactor is made by the following method: adding urease to carboxymethyl chitosan aqueous solution To obtain an aqueous solution of carboxymethyl chitosan containing enzyme, according to the molar ratio of the structural unit of carboxymethyl chitosan to 4-azidobenzaldehyde is 1: (0.1~10), the ethanol solution of 4-azidobenzaldehyde Add it to the aqueous solution of carboxymethyl chitosan, stir and mix evenly in the dark at room temperature to generate a photocrosslinkable carboxymethyl chitosan amphiphilic polymer, which self-assembles into hollow nanocapsules and at the same time The urease realizes encapsulation in situ; then the nanocapsule solution triggers the cross-linking of the azido group in the shell by ultraviolet light, and obtains the bionanogel capsule encaps...

Embodiment 2

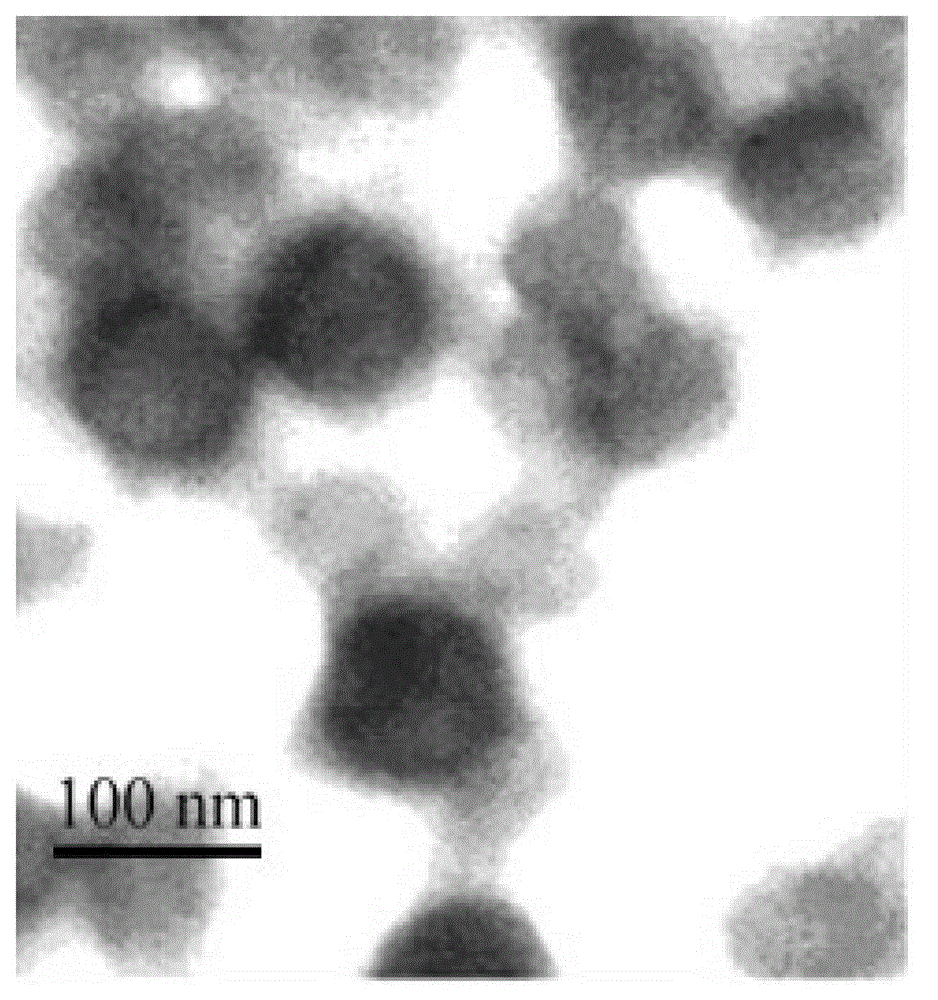

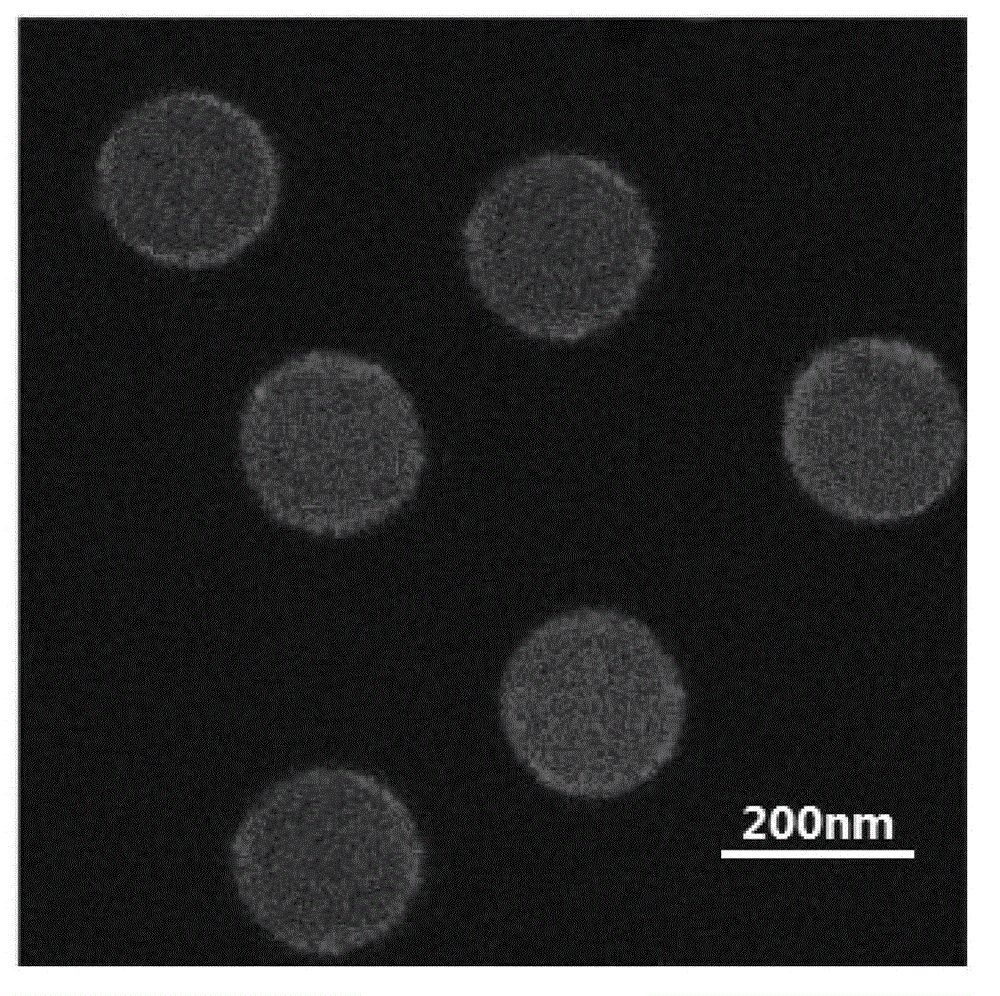

[0055] Carboxymethyl chitosan with a carboxymethyl substitution degree of 1.0 was dissolved in deionized water to prepare a carboxymethyl chitosan aqueous solution with a concentration of 0.05% by weight. Add urease to the carboxymethyl chitosan aqueous solution so that the weight percent concentration is 0.5%, and then according to the carboxymethyl chitosan structural unit and 4-azidobenzaldehyde molar ratio is 1:1.0, to carboxymethyl chitosan Add 4-azidobenzaldehyde ethanol solution (1:1 volume ratio of 4-azidobenzaldehyde to ethanol) into the sugar water solution, and stir to mix evenly in the dark to obtain photocrosslinkable Nanozyme encapsulation solution. Then, the mixed solution was irradiated by ultraviolet light (20W, 260nm) to induce azido crosslinking, and dialyzed to remove ethanol to obtain an enzyme nanoreactor solution with an average particle size of 145nm.

[0056] Adjust the pH of the solution to 3.0 to precipitate the enzyme nanoreactor from the solution....

Embodiment 3

[0058] Carboxymethyl chitosan with a carboxymethyl substitution degree of 1.2 was dissolved in deionized water to prepare a carboxymethyl chitosan aqueous solution with a concentration of 0.05% by weight. Add urease to the carboxymethyl chitosan aqueous solution so that the weight percentage concentration is 0.5%, and then according to the carboxymethyl chitosan structural unit and 4-azidobenzaldehyde molar ratio is 1:0.8, to carboxymethyl chitosan Add 4-azidobenzaldehyde ethanol solution (1:1 volume ratio of 4-azidobenzaldehyde to ethanol) into the sugar aqueous solution, and stir in the dark to mix evenly to obtain photocrosslinkable Nanozyme encapsulation solution. Then, the mixed solution was irradiated by ultraviolet light (20W, 260nm) to initiate azido cross-linking, and dialyzed to remove ethanol to obtain an enzyme nanoreactor solution with an average particle size of 165nm.

[0059] Adjust the pH of the solution to 3.0 to precipitate the enzyme nanoreactor from the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com