Metal oxide ultraviolet detector and production method thereof

An ultraviolet detector and oxide technology, applied in the field of metal oxide ultraviolet detectors, can solve the problems of high energy consumption, complex process, unfavorable popularization, etc., and achieve the effects of promoting low-temperature conversion, simple preparation process and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

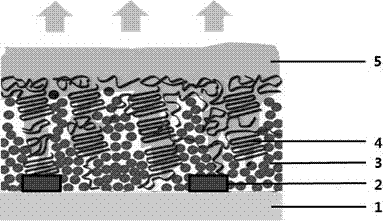

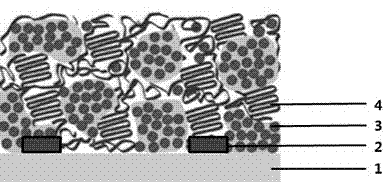

[0040] Such as figure 1 Shown: the interdigitated electrode 2 is made of gold with a thickness of 50nm, the metal oxide nanoparticles are made of zinc acetate dihydrate precursor, and its mixed layer with shellac is made of zinc oxide nanoparticles and shellac, with a thickness of 2000nm, wherein the weight ratio of zinc oxide nanoparticles to shellac is 1:1, and the diameter of zinc oxide nanoparticles is 20nm.

[0041] The preparation method is as follows:

[0042] ① Thoroughly clean the quartz glass substrate first, then dry it after cleaning;

[0043] ② Vacuum thermal evaporation of interdigitated electrodes on the surface of the quartz glass substrate;

[0044]③ Coating a mixed layer of metal oxide nanoparticles and shellac on the interdigitated electrodes;

[0045] ④Heat the device to 150°C to make the shellac in a fluid state, anneal in an ethanol atmosphere, and the annealing time is 2h;

[0046] ⑤After the annealing is completed, raise the temperature to the curin...

Embodiment 2

[0048] Such as figure 1 Shown: the preparation material of the interdigital electrode 2 is gold, the thickness is 50nm, the metal oxide particles are made of zinc acetate dihydrate, and its mixed layer with shellac is made of zinc oxide nanoparticles and shellac, and the thickness is 2000nm , wherein the weight ratio of zinc oxide nanoparticles to shellac is 1:1, and the diameter of zinc oxide nanoparticles is 5nm.

[0049] The preparation method is as follows:

[0050] ① Thoroughly clean the quartz glass substrate first, then dry it after cleaning;

[0051] ② Vacuum thermal evaporation of interdigitated electrodes on the surface of the quartz glass substrate;

[0052] ③ Coating a mixed layer of metal oxide nanoparticles and shellac on the interdigitated electrodes;

[0053] ④ Heat the device to 150°C to make the shellac in a fluid state, anneal in an ethanol atmosphere, and the annealing time is 0.5h;

[0054] ⑤After the annealing is completed, raise the temperature to th...

Embodiment 3

[0056] Such as figure 1 Shown: the preparation material of the interdigital electrode 2 is gold, the thickness is 20nm, the metal oxide particles are made of zinc acetate dihydrate precursor, and its mixed layer with shellac is formed by mixing zinc oxide nanoparticles and shellac, with a thickness of 500nm, wherein the weight ratio of zinc oxide nanoparticles to shellac is 1:10, and the diameter of zinc oxide nanoparticles is 5nm.

[0057] The preparation method is as follows:

[0058] ① Thoroughly clean the quartz glass substrate first, then dry it after cleaning;

[0059] ② Vacuum thermal evaporation of interdigitated electrodes on the surface of the quartz glass substrate;

[0060] ③ Coating a mixed layer of metal oxide nanoparticles and shellac on the interdigitated electrodes;

[0061] ④ Heat the device to 150°C to make the shellac in a fluid state, anneal in an ethanol atmosphere, and the annealing time is 0.5h;

[0062] ⑤After the annealing is completed, raise the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com