Method for preparing chiral amine through transaminase continuous reaction

A transaminase and chemical reaction technology, applied in the field of enzyme catalysis, can solve the problems such as the inability of efficient recycling and regeneration of cofactors and the loss of enzyme amount, and achieve the effect of maintaining the reaction conversion rate unchanged, the reaction conversion rate is basic, and the operation is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

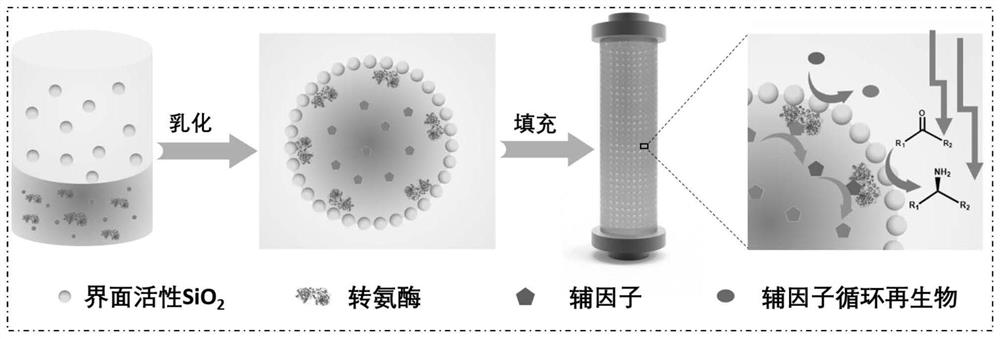

[0032] A method for preparing chiral amines through transaminase continuous reaction, comprising the steps of:

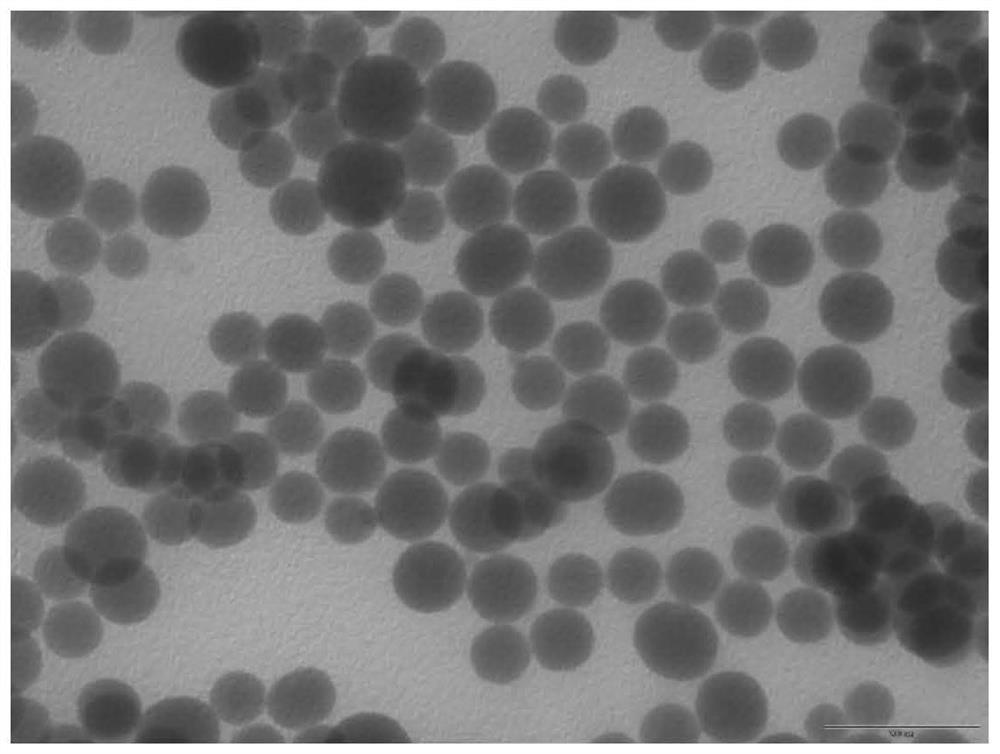

[0033] Step 1: 1.0 g of SiO with a particle size of 60 nm 2 Nanoparticles were ultrasonically dispersed into 12mL toluene, 4.5mmol octyltrimethoxysilane and 4.5mmol triethylamine were added, stirred and refluxed for 4 hours at 110°C under nitrogen protection, after cooling, the above mixed system was centrifuged to obtain a solid Wash 3-5 times with toluene and dry to obtain interface active nano-SiO 2 (Looks like figure 2 shown);

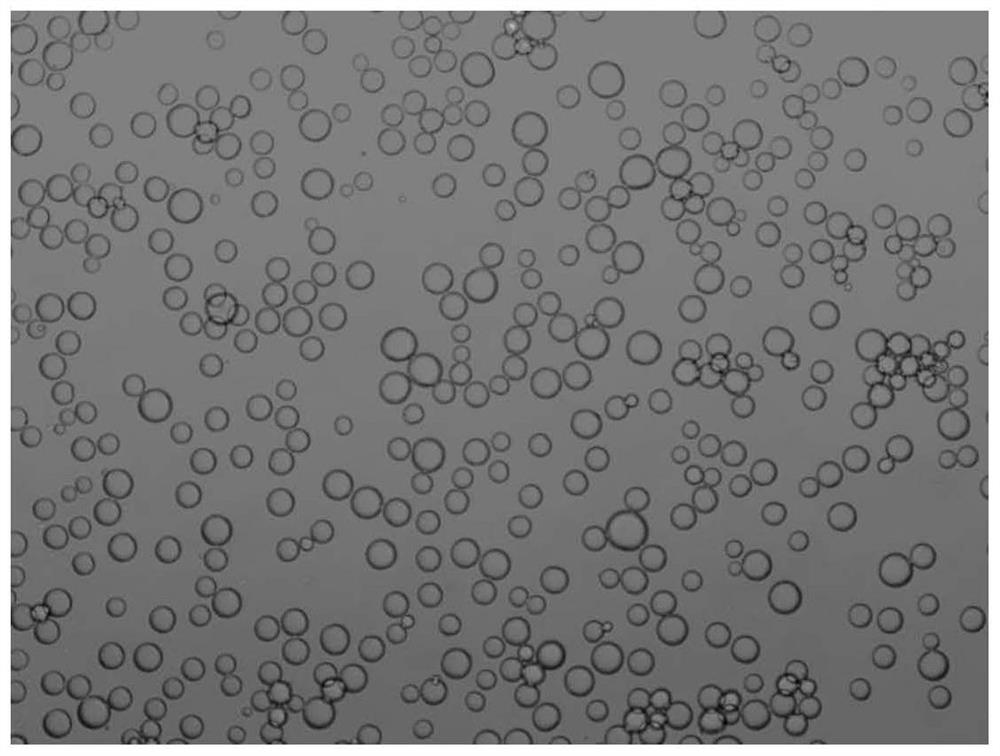

[0034] Step 2: Add 0.08mL of transaminase ATA-117 solution and 5.0mg of PLP into 3.2mL of 100mM PBS buffer solution, and mix uniformly by magnetic stirring to obtain an aqueous phase system; add 0.32g of interface-active SiO 2 Ultrasonic dispersion in 8mL n-heptane, mixed evenly to obtain an oil phase system; the oil-water two-phase system was mixed, and stirred at a high speed of 5000rpm to form a water-in-oil Pickering emulsion (mo...

Embodiment 2

[0037] A method for preparing chiral amines through transaminase continuous reaction, comprising the steps of:

[0038] Step 1: Add 1.5g of SiO with a particle size of 60nm 2 Nanoparticles were ultrasonically dispersed into 20mL toluene, 4.5mmol dichlorodimethylsilane and 2.25mmol n-hexylamine were added, stirred and refluxed for 6h at 60°C under nitrogen protection, after cooling, the above mixed system was centrifuged, and the obtained solid was used Wash with toluene 3-5 times and dry to obtain interface active nano-SiO 2 ;

[0039] Step 2: Mix 0.72mL transaminase ATA-113 solution, 40mg NADP + Add it to 6.4mL100mM PBS buffer solution, and mix it uniformly by magnetic stirring to obtain an aqueous phase system; add 0.316g of interface-active SiO 2 Ultrasonic dispersion in 16mL of toluene, mixed evenly to obtain an oil phase system; the oil-water two-phase system was mixed, and stirred at a high speed of 5000rpm to form a water-in-oil Pickering emulsion that encapsulated t...

Embodiment 3

[0042] A method for preparing chiral amines through transaminase continuous reaction, comprising the steps of:

[0043] Step 1: 1.2g of SiO with a particle size of 80nm 2 Nanoparticles were ultrasonically dispersed into 20mL toluene, 1.5mmol dichlorodimethylsilane and 4.5mmol n-hexylamine were added, stirred and refluxed for 5h at 60°C under nitrogen protection, after cooling, the above mixed system was centrifuged, and the obtained solid was used Wash with toluene 3-5 times and dry to obtain interface active nano-SiO 2 ;

[0044] Step 2: Add 0.06mL of transaminase ATA-119 solution and 10mg of PLP to 3.2mL of 100mM PBS buffer solution, and mix uniformly by magnetic stirring to obtain an aqueous phase system; add 0.158g of interfacially active SiO 2 Ultrasonic dispersion in 20mL of ethyl acetate, mixed evenly to obtain an oil phase system; the oil-water two-phase system was mixed, and stirred at a high speed of 10000rpm to form a water-in-oil Pickering emulsion encapsulating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com