Solvent for improving antioxidation metabolic capacity of flue-cured tobacco

A metabolic ability and anti-oxidation technology, applied in biocides, animal repellents, plant preservation, etc., can solve problems that do not involve the antioxidant and metabolic properties of tobacco leaves, so as to reduce adverse effects, maintain normal growth and development, and ensure production and the effect on output value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Solvent preparation: the weight percent of each component of the solvent in this embodiment is: betaine 0.25%, proline 0.10%, nano carbon sol 0.03%, and the rest is water.

[0017] Application time: In the early stage of tobacco plant growth, it is divided into 3 times of use, with an interval of 3 days between each time. From the top of the tobacco plant, spray the solvent evenly on the front and back of the tobacco leaves with a sprayer from top to bottom.

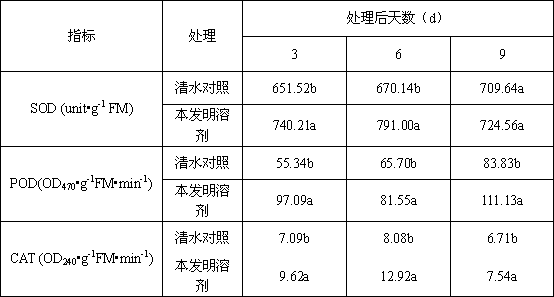

[0018] Each treatment in the test was sprayed three times in a row, and then the water supply was stopped, and the drought stress treatment was started. Fresh tobacco leaf samples in the middle of the tobacco plant were collected 3, 6, and 9 days after drought stress, respectively, and the activities of SOD, POD, and CAT were determined, as well as the contents of Pro and MDA.

[0019] Specific implementation effect:

[0020] As can be seen from Table 1, compared with the clear water contrast, after spraying the...

Embodiment 2

[0028] Repeat Example 1, the following difference is arranged: the weight percent of each component of present embodiment solvent is: betaine 0.50%, proline 0.05%, nano carbon sol 0.01%, all the other are water.

[0029] Application time: In the early stage of tobacco plant growth, it is divided into 2 times of use, with an interval of 5 days between each time.

[0030] Specific implementation effect:

[0031] It can be seen from Table 3 that compared with the clear water control, after spraying the solvent of the present invention, the SOD, POD and CAT activities of the flue-cured tobacco leaves were significantly improved, effectively improving the antioxidant metabolism of the tobacco leaves.

[0032] Table 3 Changes of antioxidant metabolic enzymes in flue-cured tobacco after spraying solvent

[0033]

[0034] Table 4 finds that compared with the clear water contrast, after spraying the solvent of the present invention, the content of proline (Pro) in flue-cured tobacc...

Embodiment 3

[0038] Repeat Example 1, the following difference is arranged: the weight percent of each component of the present embodiment solvent is: betaine 0.10%, proline 0.25%, nano carbon sol 0.05%, all the other are water.

[0039] Application time: In the early stage of tobacco plant growth, it is divided into 3 times of use, with an interval of 5 days between each time.

[0040] Specific implementation effect:

[0041] It can be seen from Table 5 that compared with the clear water control, after spraying the solvent of the present invention, the SOD, POD and CAT of the flue-cured tobacco leaves increased by 7.87%, 16.72% and 14.17% on average respectively, effectively improving the antioxidant metabolism of the tobacco leaves.

[0042] Table 5 Changes of antioxidant metabolic enzymes in flue-cured tobacco after spraying solvent

[0043]

[0044] Table 6 finds that, compared with the clean water contrast, after spraying the solvent of the present invention, the content of prolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com