All-fiber superfluorescent light source

A super-fluorescence and all-fiber technology, applied in the field of laser communication, can solve the problems of damaging the pump source or gain fiber, laser oscillation, and affecting the super-fluorescence output, and achieve the effects of reducing reflectivity, increasing output power level, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment describes an all-fiber superfluorescent light source, including: a gain fiber and a pump source, the pump source fiber is connected to the side of the gain fiber; the gain fiber is a complete one.

Embodiment 2

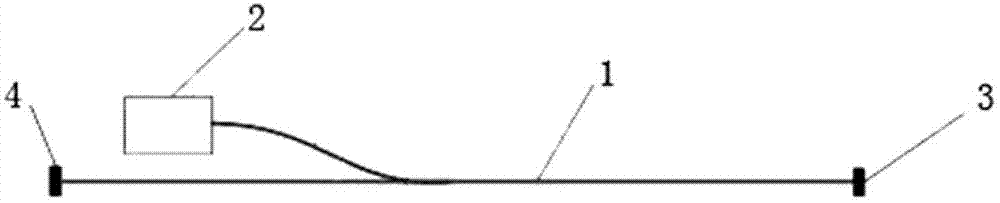

[0027] Such as figure 1 As shown, this implementation describes a single-point side connection, single-ended output all-fiber superfluorescent light source, including: a gain fiber 1 and a pumping source 2, a gaining fiber 1 runs through to the end, and the pumping source 2 optical fibers The connection to the side of the gain fiber 1 can be fusion splicing, colloid bonding, or direct bonding. There is one connection point, that is, one pump source.

[0028] The end face of the gain fiber 1 is subjected to feedback reduction treatment, such as angle cutting, angle polishing, or immersion in a refractive index matching solution. One end is a low-reflection end 3 with a reflectivity lower than 0.001%, and the other end is a high-reflection end 4 with a reflectivity higher than 1%. Hyperfluorescence is output from the low reflection end.

[0029] Gain fiber 1 is a gain fiber that is doped with various gain particles including erbium, ytterbium, neodymium, thulium and neodymium ...

Embodiment 3

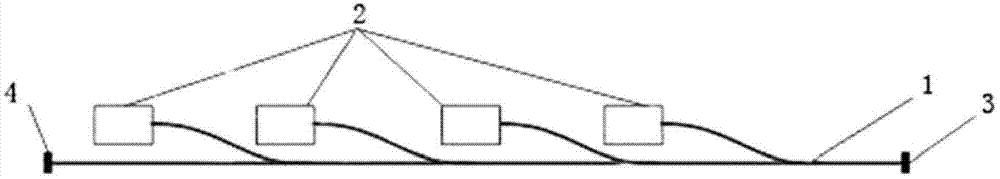

[0032] Such as figure 2 As shown, this implementation records an all-fiber superfluorescent light source with single-point side connection and double-ended output. Its structure is basically similar to that of Embodiment 2, the only difference is that both ends of the gain fiber are processed into low-reflection ends 3. Its reflectivity is lower than 0.001%, and superfluorescence is output from both ends of the gain fiber simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com