Composite cathode material of medium/low-temperature proton transport solid oxide fuel cell

A solid oxide, composite cathode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low ionic conductivity, limited three-phase interface, etc., achieve good sulfur poisoning, enhanced bonding strength, good carbon deposition phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Synthesis and chemical compatibility test of a composite cathode material with two phases each accounting for 50wt%

[0022] Press Nd 1.95 NiO 4+δ The stoichiometric ratio, weigh an appropriate amount of Nd 2 o 3 , the Nd 2 o 3 Dissolve in dilute nitric acid solution, then add Ni(NO 3 ) 2 ·6H 2 0, by metal ion: citric acid 1:1.5 ratio complexing agent monohydrate citric acid is added in the above-mentioned aqueous solution; Utilize magnetic stirrer to mix solution, 80 ℃ of water bath heatings remove unnecessary moisture, obtain gelatinous liquid; Put the gel-like liquid into a ceramic element dish, heat it on a resistance wire furnace until it is completely burned, and obtain an oxide precursor; the precursor is heat-treated at 1100°C for 6 hours to obtain a pure phase of Nd 1.95 NiO 4+δ Powder. Preparation of BaZr 0.1 Ce 0.7 Y 0.1 Yb 0.1 o 3-δ , weigh an appropriate amount of Yb 2 o 3 , will Yb 2 o 3 Dissolve in concentrated nitric acid so...

Embodiment 2

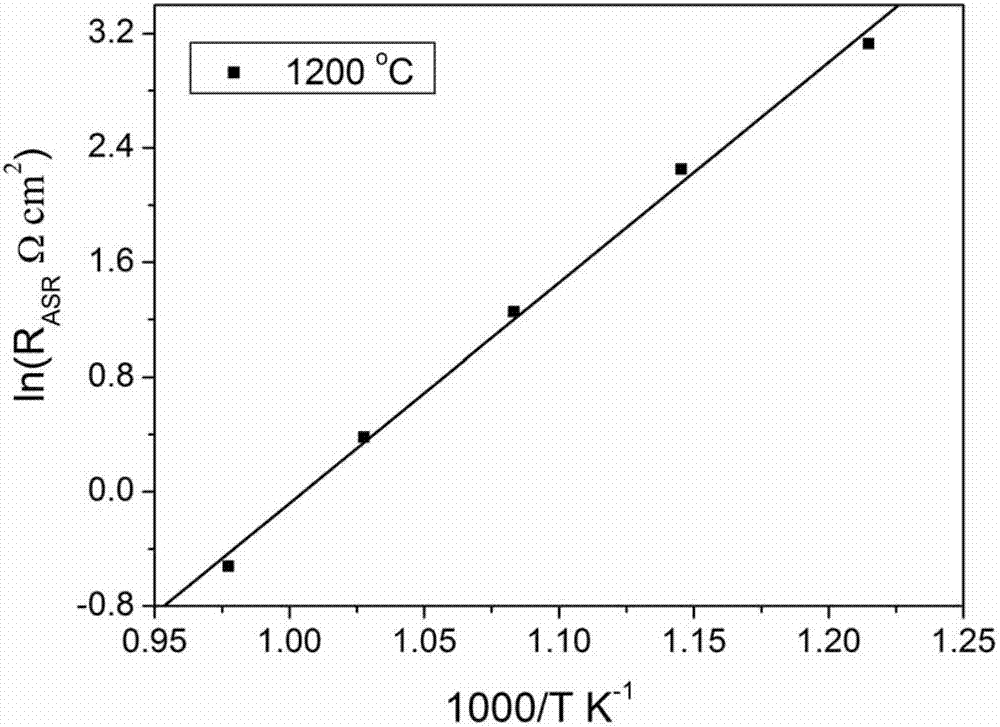

[0024] Example 2: Test of interfacial resistance at different sintering temperatures of composite cathode materials with two phases each accounting for 50wt%

[0025] The composite cathode powder is obtained by mixing the synthesized two-phase cathode materials uniformly at a mass ratio of 1:1. A certain amount of composite cathode material powder and pore-forming agent soluble starch are uniformly mixed at a mass ratio of 8:2, and then a mixed solution of terpineol containing 10% ethyl cellulose is added to the uniformly mixed powder as Binder, the mass ratio of powder and binder is 6:4. The mixture was thoroughly ground until a uniform viscous cathode material slurry was obtained. Then the paste was uniformly coated on the dense BaZr by screen printing method 0.1 Ce 0.7 Y 0.1 Yb 0.1 o 3-δ After the surface of the electrolyte sheet was dried in an oven, it was placed in a high-temperature furnace and calcined at 1150, 1200, and 1250°C for 3 hours to obtain a symmetrical...

Embodiment 3

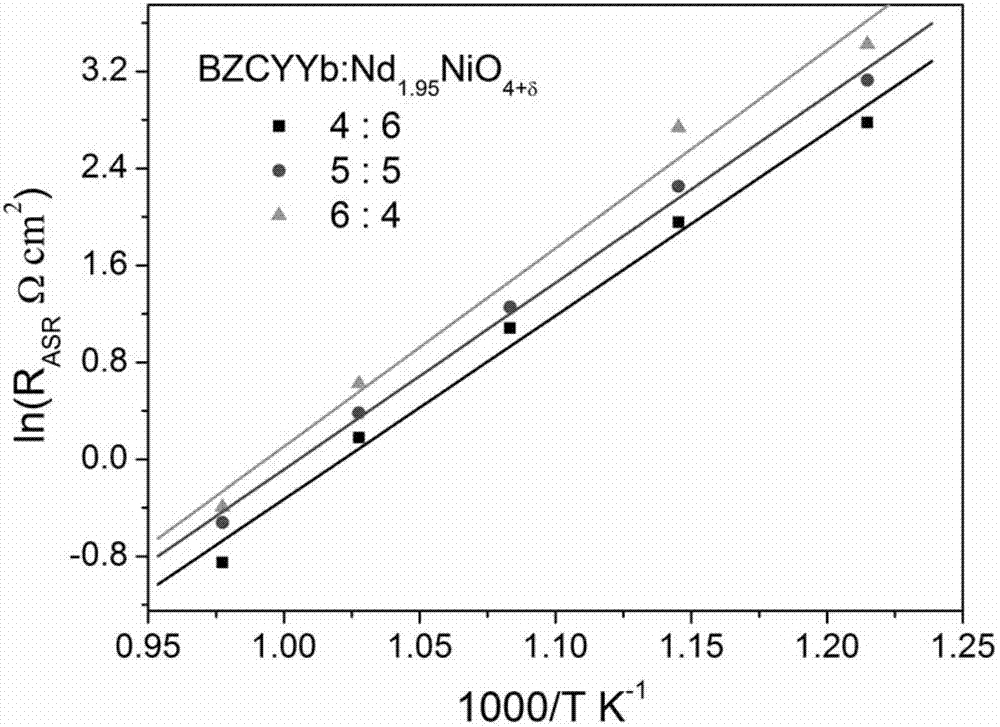

[0027] Example 3: Testing of the polarization impedance of symmetrical batteries with different proportions of the two phases of the composite cathode

[0028] The synthesized two-phase cathode material BaZr 0.1 Ce 0.7 Y 0.1 Yb 0.1 o 3-δ : Nd1.95 NiO 4+δ Mix evenly according to the mass ratio of 4:6, 5:5 and 6:4 to obtain composite cathode powder. A certain amount of composite cathode material powder and pore-forming agent soluble starch are uniformly mixed at a mass ratio of 8:2, and then terpineol containing 10% ethyl cellulose is added to the uniformly mixed powder as a binder , The mass ratio of powder to binder is 6:4. The mixture was thoroughly ground until a homogeneous viscous cathode material slurry was obtained. Then the paste was uniformly coated on the dense BaZr by screen printing method 0.1 Ce 0.7 Y 0.1 Yb 0.1 o 3-δ After the surface of the electrolyte sheet is dried in an oven, it is placed in a high-temperature furnace and calcined at a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com