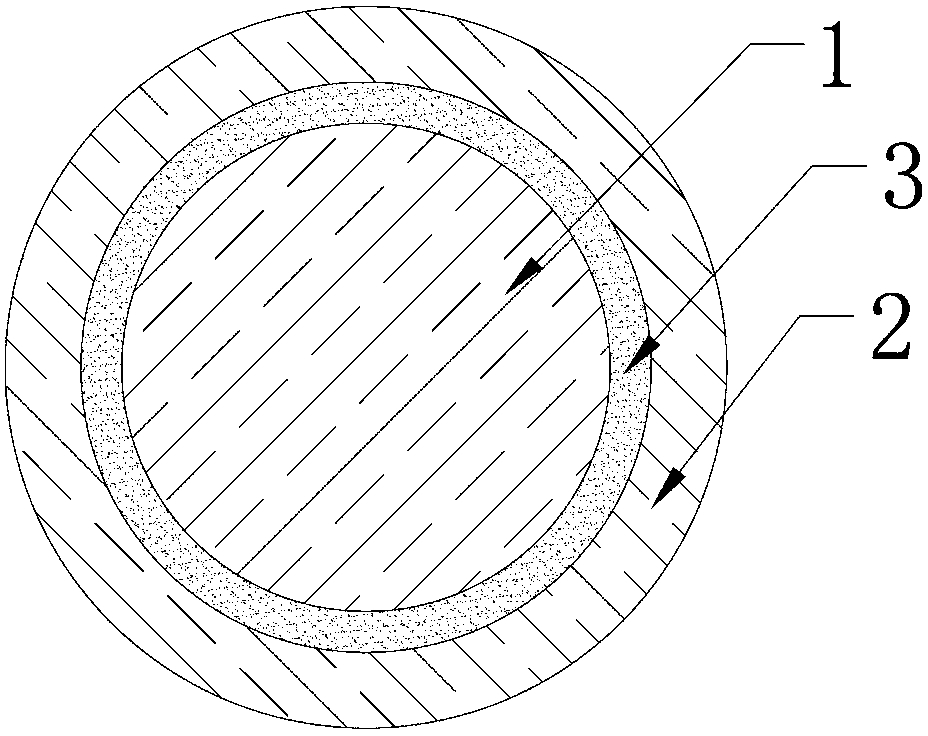

High-adhesive-force PVC (polyvinyl chloride) plastic coating steel wire and production method thereof

A technology of adhesion and steel wire, applied in the field of PVC coated steel wire, can solve the problems of peeling off of coating and steel wire, poor adhesion between steel wire and PVC coating, affecting service life and safety, etc., to increase adhesion , Improve the effect of safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Example 1: The production method of a high -bond PVC plastic wire, the steps are as follows:

[0028] (1) Rush the φ3.0mm raw material steel wire with a high -temperature steam at 160 ° C for 4 minutes to remove the lubrication powder and floating ash on the surface of the wire;

[0029] (2) Washing the above -mentioned steel wires that have been washed with steam for 5 minutes through the alkaline water solution in the ultrasonic device to remove the oil and impurities on the surface of the wire;The amount of sodium hydroxide is 50 g / L, and sodium carbonate is 30 g / L; the temperature of the sodium phosphate is 30 g / L; the temperature of the alkaline water solution is 70 ° C;

[0030] (3) Wash the steel wire after being cleaned by the ultrasonic device in the step (2) for 5 minutes with a hot water of 90 ° C, then wash it with room temperature for 5 minutes, and then dry the steel wire in a 125 ° C oven;

[0031] (4), 20 kg of diopine 35kg, aromatic isocyanate 20 kg, 4,4'-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com