Method for preparing nanometer microcrystalline cellulose by combining acid hydrolysis and ultrasonic treatment

A nano-crystal, ultrasonic treatment technology, applied in fiber raw material processing, textiles and papermaking, etc., to achieve the effects of easy operation and control, simple preparation process, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1. Sulfuric acid hydrolysis of cellulose: First, add concentrated sulfuric acid into distilled water to prepare a sulfuric acid solution with a mass concentration of 65%. The sulfuric acid solution to be diluted is cooled to room temperature. Slowly add TONNOR EM100 powder provided by Shanghai Tonghua New Material Technology Co., Ltd., and start timing after mixing evenly. After reacting for 120 minutes, add water to terminate the reaction, and obtain a mixed solution of nano-microcrystalline cellulose prepared by acid hydrolysis. 2. Preparation of nano-microcrystalline cellulose colloid: first, the nano-microcrystalline cellulose mixture prepared by acid hydrolysis obtained in step 1 was centrifuged in a centrifuge whose rotational speed was set to 11000 r / min and time was set to 10 min, and centrifuged for 3 The nano-microcrystalline cellulose colloid can be collected in ~6 times, and the collected nano-microcrystalline cellulose colloid is placed in a dialysis bag wit...

Embodiment 2

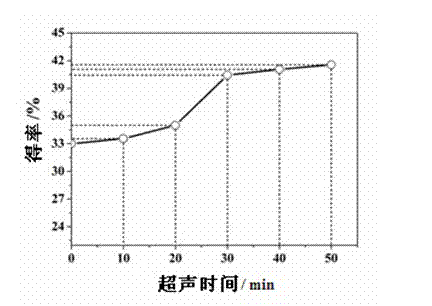

[0015] 1. Sulfuric acid hydrolysis and ultrasonic treatment of cellulose: First, add concentrated sulfuric acid into distilled water to prepare a sulfuric acid solution with a mass concentration of 65%. The sulfuric acid solution to be diluted is cooled to room temperature. At the same time, slowly add TONNOR EM100 powder provided by Shanghai Tonghua New Material Technology Co., Ltd., and start timing after mixing evenly. After 110 minutes of reaction, 10 minutes of ultrasonic cleaning in an ultrasonic cleaner with a power of 100W, water is added to terminate the reaction, and acid hydrolysis and Ultrasonic treatment of co-prepared nano-microcrystalline cellulose mixture. 2. Preparation of nano-microcrystalline cellulose colloid: first, the nano-microcrystalline cellulose mixture prepared in step 1 by acid hydrolysis and ultrasonic treatment was centrifuged in a centrifuge with a speed of 11,000 r / min and a time of 10 min. After separation and centrifugation for 3 to 6 times, ...

Embodiment 3

[0017] 1. Sulfuric acid hydrolysis and ultrasonic treatment of cellulose: First, add concentrated sulfuric acid into distilled water to prepare a sulfuric acid solution with a mass concentration of 65%. The sulfuric acid solution to be diluted is cooled to room temperature. At the same time, slowly add TONNOR EM100 powder provided by Shanghai Tonghua New Material Technology Co., Ltd., and start timing after mixing evenly. After 100 minutes of reaction, 20 minutes of ultrasonic cleaning in an ultrasonic cleaner with a power of 100W, water is added to terminate the reaction, and acid hydrolysis and Ultrasonic treatment of co-prepared nano-microcrystalline cellulose mixture. The reaction was terminated by adding water, and the nano-microcrystalline cellulose mixed solution prepared by acid hydrolysis and ultrasonic treatment was obtained. 2. Preparation of nano-microcrystalline cellulose colloid: first, the nano-microcrystalline cellulose mixture prepared in step 1 by acid hydrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com