Preparation method of hollow metal microspheres

A metal microsphere and hollow technology, applied in the field of composite materials, can solve the problems of complex process, influence product quality, complex processing process, etc., and achieve the effects of short reaction time, easy control of process conditions, and simple processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Take 1 mL of chloroauric acid solution with a mass concentration of 13.6 g / L and dilute it to 150 mL, and adjust the pH between 6 and 7 with sodium hydroxide (40 g / L) solution. After heating the solution to boiling, add 1.4 mL of sodium citrate (25.8 g / L) solution, and stir magnetically until the color of the solution turns ruby red to obtain gold nanoparticles.

[0028] (2) 125mg tetra-n-butyl titanate (Ti(OC 4 h 9 ) 4 ) into 10 mL of ethylene glycol, stirred magnetically at room temperature for 8 hours, then quickly added 50 mL of acetone (containing 150 μL of ultrapure water), stirred magnetically at room temperature for 1 hour, centrifuged, washed, and dried to obtain titanium dioxide.

[0029] (3) Take 10 mg of titanium dioxide and 250 μL of silane coupling agent (APTMS) and mix and stir at room temperature for 12 hours, centrifuge, wash, and dry to obtain surface-functionalized titanium dioxide.

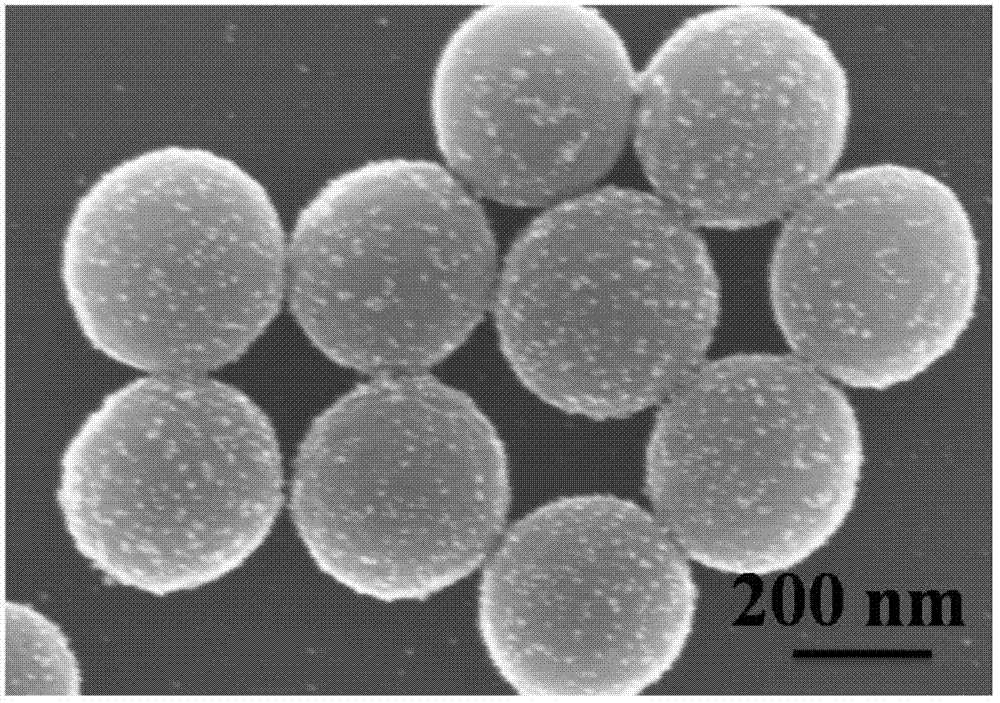

[0030] (4) Take 120mL of gold nanoparticles and surface-fu...

Embodiment 2

[0033] The difference between this example and Example 1 is that the silane coupling agent used is 1000 μL, and the rest is the same as Example 1. The Au / TiO of embodiment 2 gained 2 The SEM pictures of the samples are shown in figure 2 .

Embodiment 3

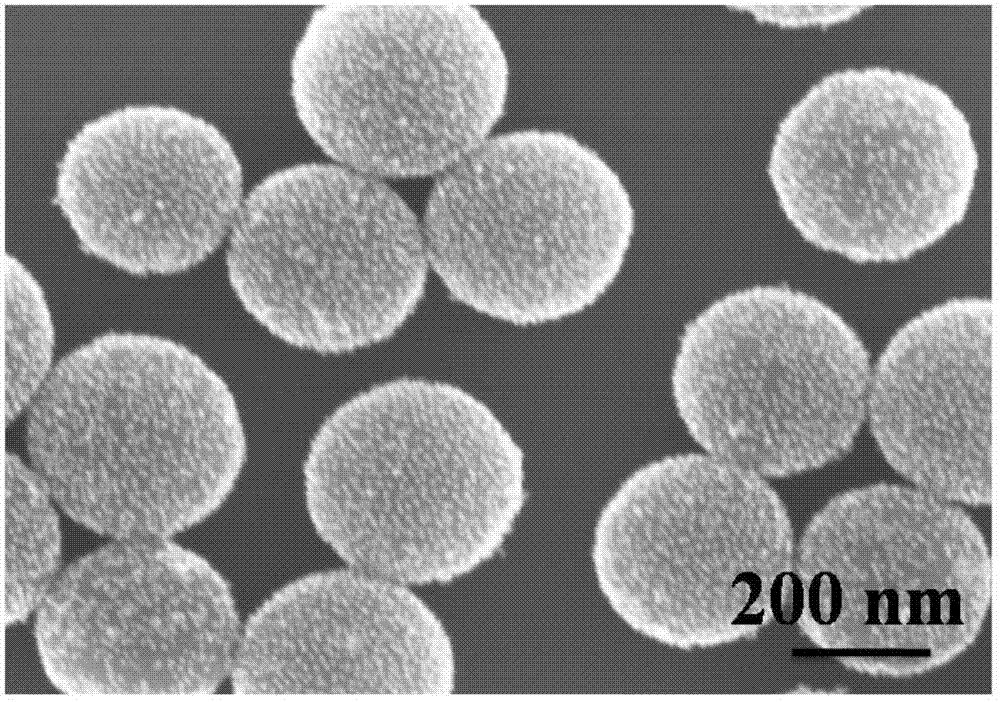

[0035] The preceding steps are the same as in Example 1. Take 1mL Au / TiO 2 Set the volume to 30mL, heat the solution to 100°C, add 3mL of citric acid (19.2g / L), 0.3mL of chloroplatinic acid (13.8g / L) and 1.0mL of vitamin C (17.6g / L), and then continue React for 0.5 h, centrifuge and wash several times to obtain PtAu hollow microspheres. The SEM pictures of the PtAu hollow microspheres obtained in embodiment 3 are shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com