Phosphate-based anode composite material of Li-ion battery and preparation method and functions thereof

A technology of composite materials and ion batteries, which is applied in the field of lithium-ion batteries and electrode materials, and can solve problems such as poor cycle life, unstable lattice structure, and low voltage platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

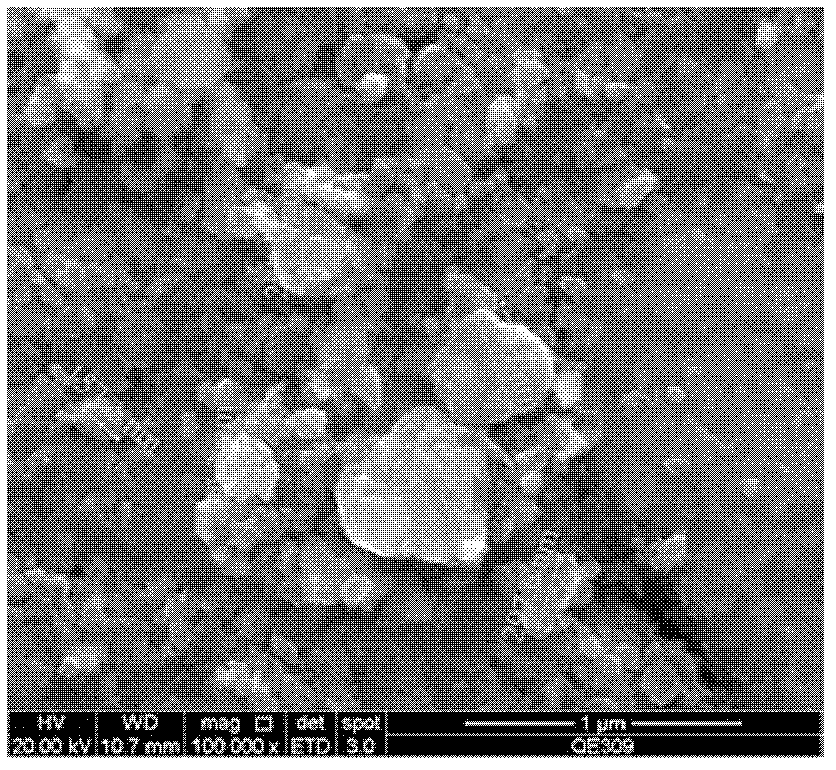

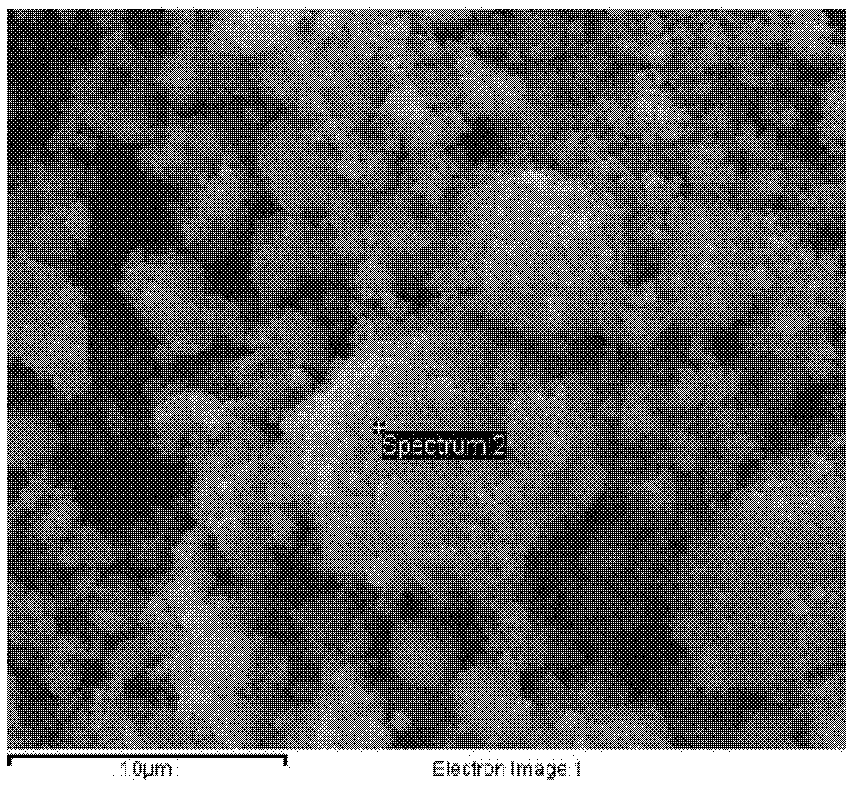

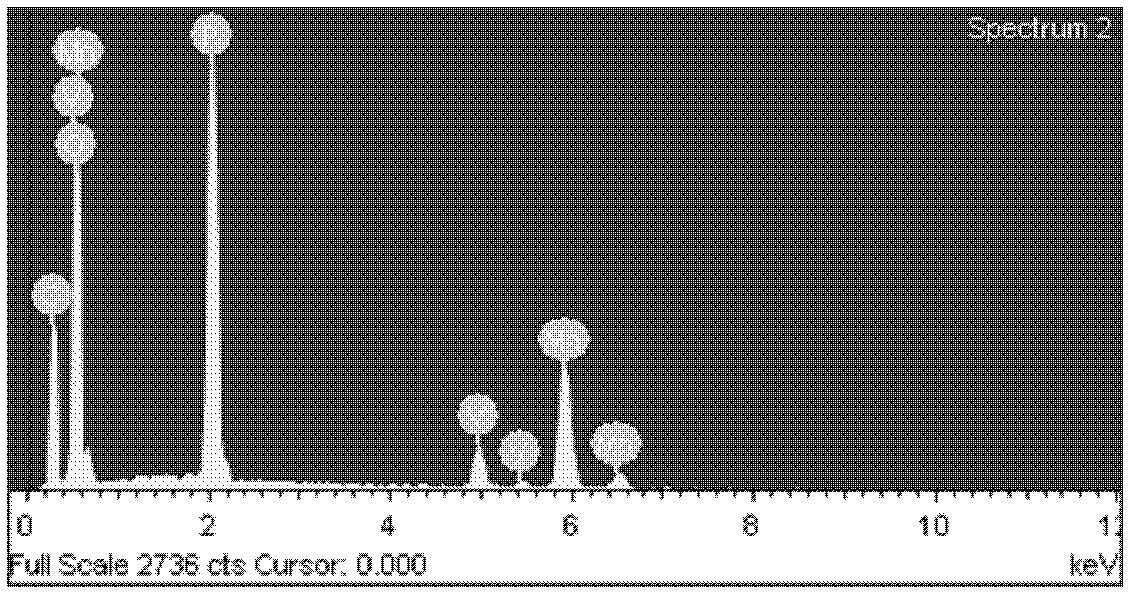

Image

Examples

preparation example Construction

[0103] Preparation of cathode composite materials for phosphate-based lithium-ion batteries

[0104] The lithium source material, manganese source material, iron source material, vanadium source material, phosphate source material, carbon source material and equipment required in the preparation method of the invention can all be purchased in the market. For experimental methods that do not indicate specific conditions, usually follow the conventional conditions or the conditions suggested by the manufacturer. For example, the precursor processing equipment is: high-energy ball mill, stainless steel tank and stainless steel ball; in the argon-hydrogen mixture, the hydrogen content is 0-10%, and the impurity content is less than 0.01%; the ball mill adopts a planetary ball mill, stainless steel ball and tank, the ball diameter 10mm, dry grinding process, etc.

[0105] LiMn described in the present invention 1-x Fe x PO 4 and Li 3 V 2 (PO 4 ) 3 The recombination method o...

Embodiment 1

[0154] Example 1 Preparation of Phosphate-Based Lithium-ion Battery Positive Electrode Composite Material 1

[0155] a, get lithium dihydrogen phosphate, manganese carbonate, iron oxalate, ammonium metavanadate, sucrose as raw material, take by weighing raw material by lithium, manganese, vanadium, phosphorus, carbon element molar ratio is 1.10: 0.95: 0.1: 1.10: 1.57, After pre-mixing in a mortar, add absolute ethanol as a dispersant, and put it in a high-energy ball mill for 4 hours to prepare the precursor.

[0156] b. Put the precursor of step a into a tube furnace, heat up at a heating rate of 5°C / min, feed argon-hydrogen mixture, heat up to 350°C and roast for 8 hours;

[0157] c. Take out the product of step b and place it in a planetary ball mill for ball milling without adding dispersant, at a speed of 400 r / min, and the ball milling time is 2 hours.

[0158] d. Put the mixture in step c into a tube furnace, raise the temperature at a heating rate of 5°C / min, feed arg...

Embodiment 2

[0162] Example 2 Preparation of Phosphate-Based Lithium-ion Battery Positive Electrode Composite Material 2

[0163] a. Get lithium dihydrogen phosphate, manganese carbonate, iron oxalate, ammonium metavanadate, and glucose as raw materials, and the molar ratio of lithium, manganese, iron, vanadium, phosphorus, and carbon is 2.00: 0.40: 0.10: 1.00: 2.00: 2.15 Weigh the raw materials, put them in a mortar and pre-mix them evenly, add absolute ethanol as a dispersant, put them in a high-energy ball mill for 4 hours to prepare the precursor.

[0164] b. Put the precursor of step a into a tube furnace, heat up at a heating rate of 10°C / min, feed high-purity argon, heat up to 450°C and roast for 8 hours;

[0165] c. The product of step b is taken out and placed in a planetary ball mill for ball milling without adding dispersant at a rotational speed of 500 r / min, and the ball milling time is 5 hours.

[0166] d. Put the mixture in step c into a tube furnace, raise the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com