LED light source structure with high illuminating power and improved heat dissipating characteristics

A technology of LED light source and structure, applied in the direction of light source, point light source, slender light source, etc., can solve problems such as the decline of heat dissipation effect, achieve the effect of stable resistance, solve the sharp rise in temperature, and prevent voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

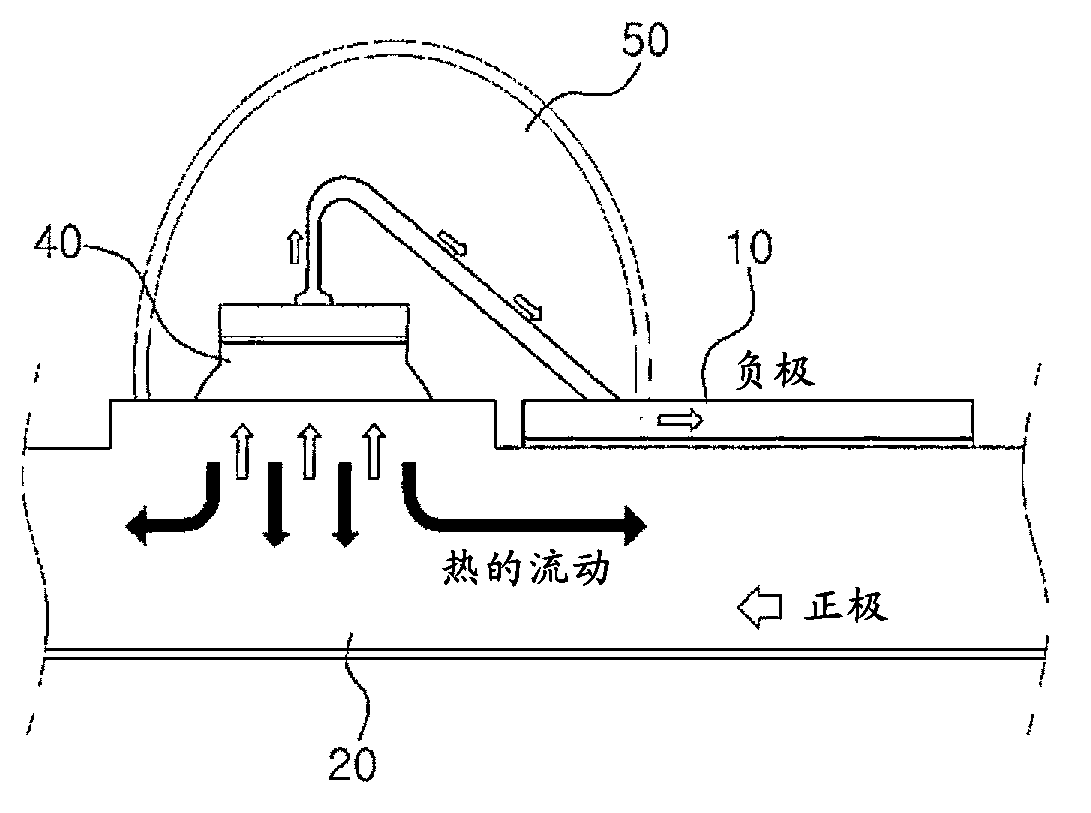

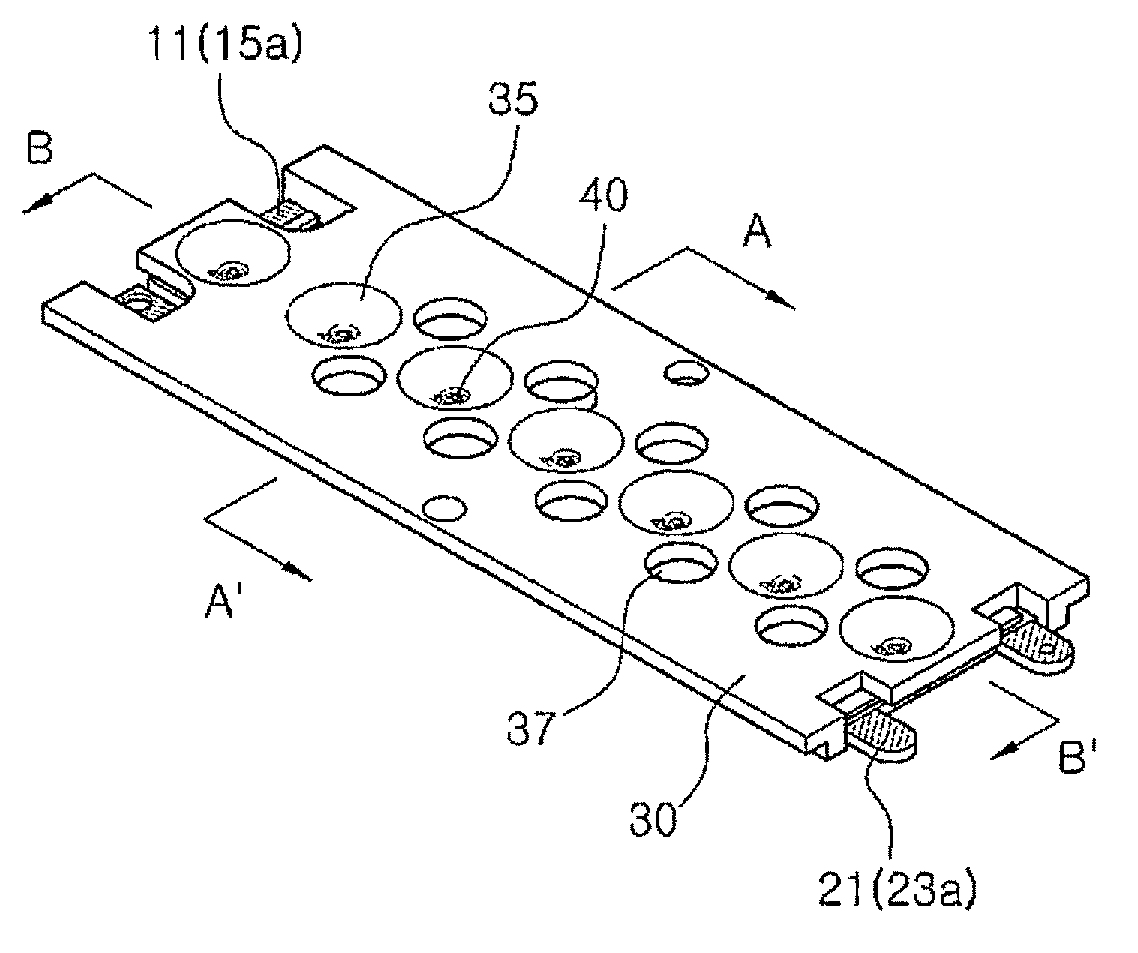

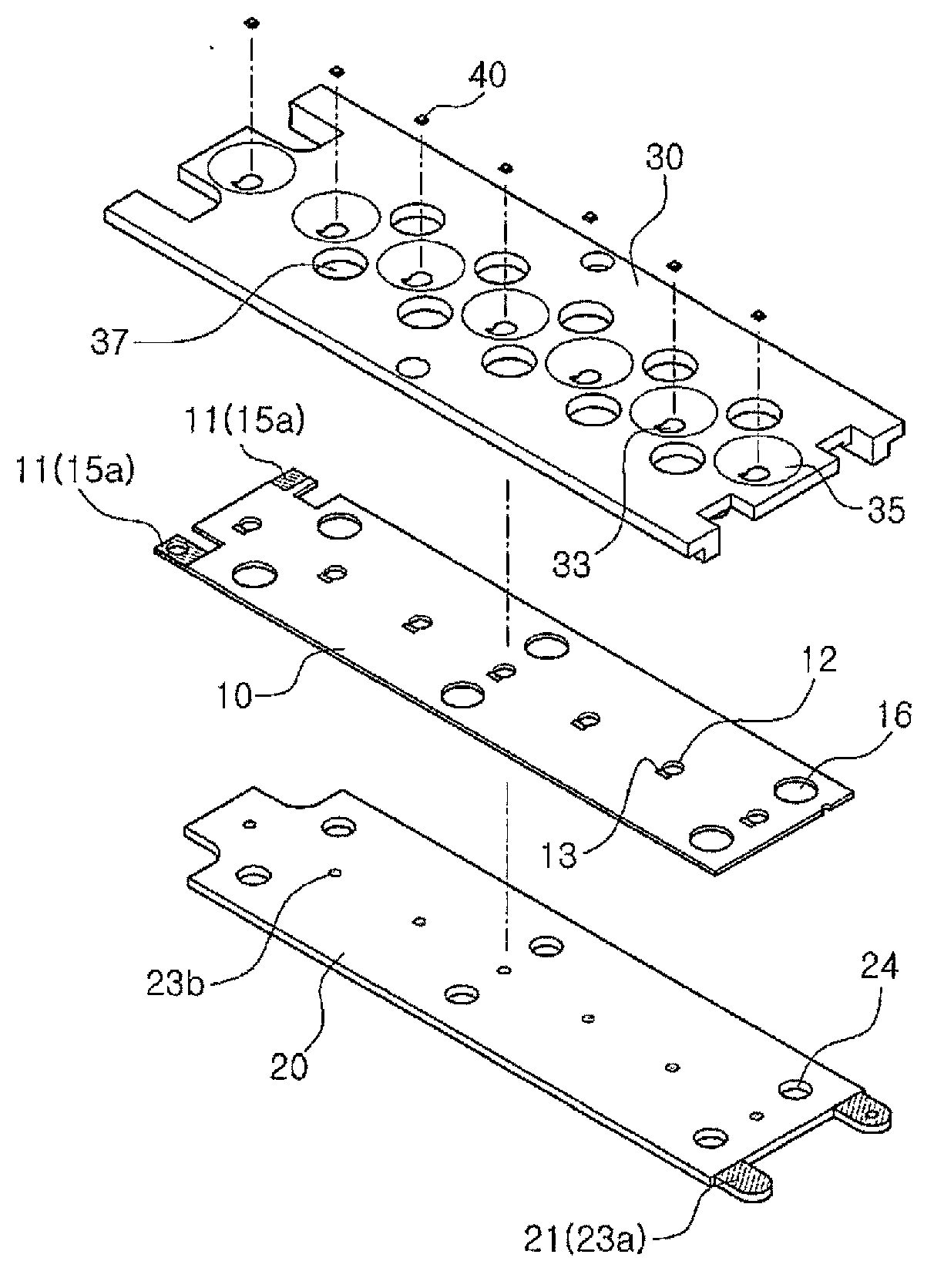

[0060] figure 1 is a conceptual diagram illustrating the structure of an LED light source structure with improved heat dissipation characteristics according to a first embodiment of the present invention, figure 2 is a perspective view illustrating the configuration of the LED light source structure according to the first embodiment, image 3 is an exploded perspective view illustrating the configuration of the LED light source structure according to the first embodiment, Figure 4 is according to image 3 The sectional view of the A-A' line, Figure 5 is according to image 3 The sectional view of the B-B' line, Figure 6 is a perspective view illustrating a state in which a plurality of LED light source structures according to the first embodiment are combined.

[0061] As shown in the figure, the LED light source structure according to the present invention includes: a first electrode unit 10 and a second electrode unit 20 made of a metal body with excellent electrica...

no. 2 example

[0091] The second embodiment of the high-luminosity LED light source structure with improved heat dissipation characteristics of the present invention will be described below. In this embodiment, the same reference numerals are used for constituent elements corresponding to those of the first embodiment.

[0092] Figure 7 is a cross-sectional view illustrating an LED light source structure according to a second embodiment of the present invention, and is illustrated in accordance with image 3 The A-A' line in the figure cuts the deformation form of the cut surface after the LED light source structure is cut.

[0093] As shown in the figure, in this embodiment, in order to increase the mounting height of the LED chip 40 and improve light output, a second electrode portion 26 protruding toward the through hole 12 is formed on the second electrode unit 20 . At this time, the second electrode part 26 can be formed as the protrusion by using a plate material with protrusions as...

no. 3 example

[0100] Figure 8 is a perspective view of an LED light source structure according to a third embodiment of the present invention, Figure 9 is a side view of an LED light source structure according to a third embodiment of the present invention, Figure 10 is an exploded perspective view of an LED light source structure according to a third embodiment of the present invention, Figure 11 is a side sectional view of an LED light source structure according to a third embodiment of the present invention, Figure 12 is a top view of the LED light source structure according to the third embodiment of the present invention.

[0101] Such as Figure 8 to Figure 12 As shown, in the fourth embodiment of the high-luminosity LED light source structure with improved heat dissipation characteristics according to the present invention, the metal body with excellent electrical and thermal conductivity, that is, the second electrode unit 20 is formed to have the shape of a heat sink 60, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com