Ionic liquid modified marine antifouling paint

A technology of marine antifouling and antifouling coatings, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problem of low surface energy, achieve low surface energy, and enhance the antifouling period effect , Excellent long-term antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

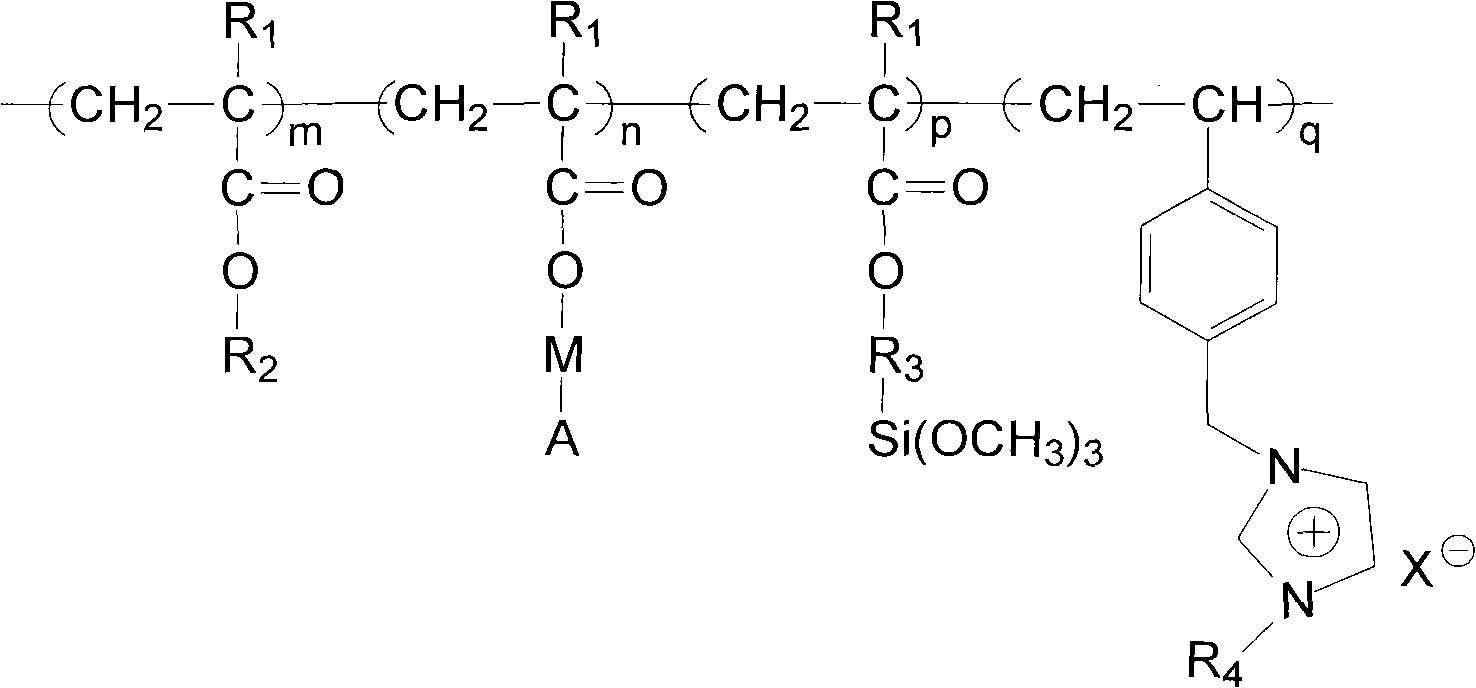

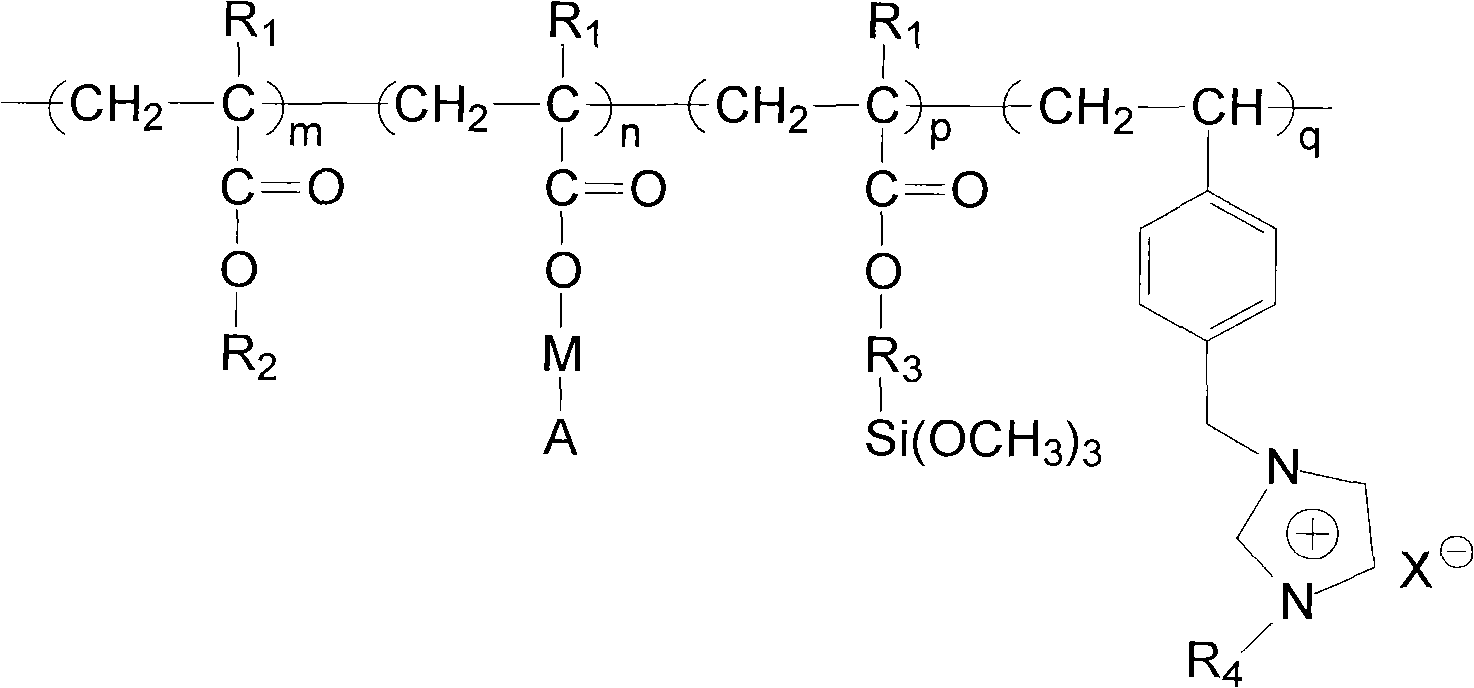

[0034] The preparation of hydrophobic ionic liquid monomer among the present invention is as follows:

[0035] Add 82 grams of N-methylimidazole, 165 grams of chloromethylstyrene, and 0.5 grams of polymerization inhibitor 2,6-di-tert-butyl-p-cresol (DBMP) into a reaction flask. Under the protection of nitrogen, stir at a constant temperature of 35°C for 24 hours to form a yellowish viscous liquid, wash with ether, and dry under vacuum at room temperature overnight to obtain a transparent, viscous liquid 1-(4-vinylbenzyl-)-3-methylimidazole chlorine. Then 18 grams of ammonium hexafluorophosphate or 12.1 grams of sodium tetrafluoroborate and 100 ml of acetone were mixed evenly and then added to 27.6 grams of 1-(4-vinylbenzyl-)-3-methylimidazole chloride, 0.2 grams of polymerization inhibitor DBMP , 100ml of acetone, stirred at 30°C for 24 hours, then filtered, and the filtrate was distilled under reduced pressure to obtain a white waxy solid. The crude product was washed with w...

Embodiment 1

[0039] (1) 46 parts of acrylic acid prepolymers containing ionic liquid groups, 5.7 parts of zinc hydroxide, 20 parts of xylene and butyl acetate mixed solvent with a mass ratio of 1; 1 were added to the reaction flask, and 8 parts of perfluorooctanoic acid, Dissolve 4.7 parts of benzoic acid in 15.6 parts of mixed solvent, add the above organic acid mixed solution dropwise at 95°C under nitrogen purging, keep the reflux state until the reaction solution is transparent, then raise the temperature to 125°C for dehydration until the water is completely removed, and a transparent, Viscous base resin for antifouling coatings containing ionic liquid groups.

[0040] (2) Add the above-mentioned antifouling coating matrix resin containing ionic liquid groups, wetting and dispersing agent and mixed solvent into the dispersion tank, fully disperse for 10 minutes, then add composite antifouling agent, pigment and filler, leveling agent, defoaming agent in sequence The anti-sedimentation...

Embodiment 2

[0050] (1) 45 parts of acrylic acid prepolymers containing ionic liquid groups, 5.5 parts of zinc hydroxide, 20 parts of xylene and butyl acetate mixed solvent with a mass ratio of 1; 1 are added to the reaction flask, and 12.4 parts of perfluorooctanoic acid 1. Dissolve 3.2 parts of benzoic acid in 14 parts of mixed solvent, add the above organic acid mixed solution dropwise at 95°C under nitrogen purging, keep the reflux state until the reaction solution is transparent, then raise the temperature to 125°C for dehydration, until the water is completely released, and a transparent , viscous antifouling coating matrix resin containing ionic liquid groups.

[0051] (2) The preparation process of the present example marine antifouling paint is the same as in Example 1.

[0052] The composition ratio of marine antifouling paint in this example is as follows:

[0053] Antifouling coating matrix resin containing ionic liquid groups: 30 grams

[0054] Composite antifouling agent: 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com