Sapphire splicing method, sapphire window and paste size

A technology of sapphire and pasting paste, which is applied in the field of sapphire window and pasting paste, sapphire splicing, which can solve the problems of high cost, failure to meet aperture requirements, and long acquisition cycle, and achieve the effect of reducing connection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

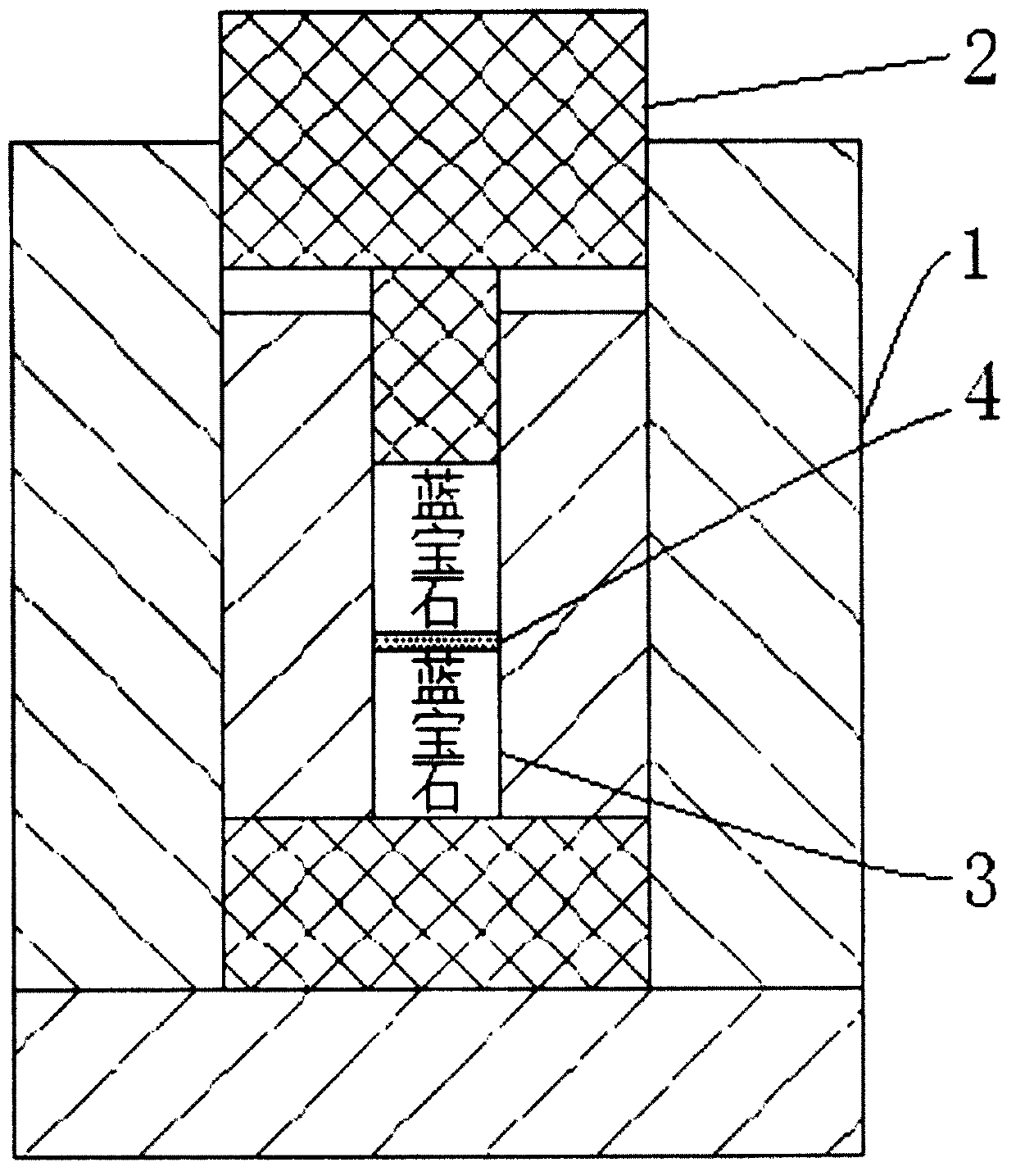

Image

Examples

Embodiment 1

[0046] In this embodiment, two connection processes of glass brazing method and reaction sintering method are used to design the solder system and connection process, screen out the appropriate solder system, and obtain the best solder composition and connection process parameters; four-point bending Strength test the mechanical properties of sapphire crystal connection joints, analyze its influencing factors, and obtain the best process parameters; use various analysis and testing methods (SEM, EDS, etc.) to observe and analyze the microscopic morphology of sapphire crystal connection joints and the distribution of elements in the joints Based on the analysis of the connection mechanism, optimize the design of the interlayer system and connection process to improve the connection performance.

[0047] Based on the above tests and analysis, the inventor provides a low-cost sapphire crystal splicing method:

[0048] 1. Cut the artificial sapphire crystal into the corresponding ...

Embodiment 2

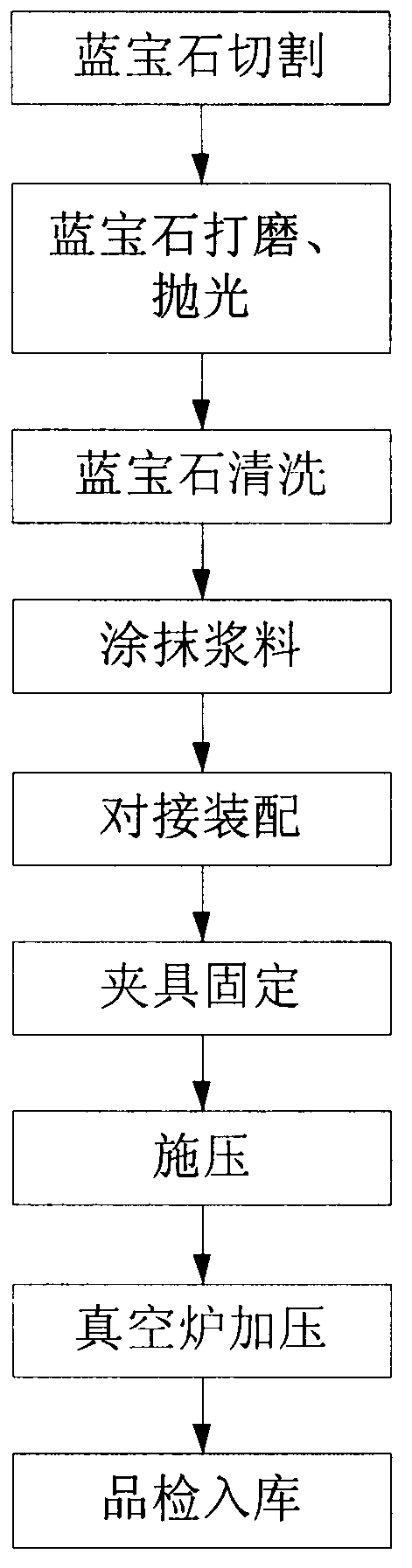

[0056] Such as figure 2 As shown, the present embodiment discloses a sapphire splicing method, comprising steps:

[0057] a. Cut the sapphire crystals into corresponding sizes, and the joint surfaces of the sapphire crystals to be spliced are of the same size and parallel to each other;

[0058] b. Grinding the joint surface of sapphire, and then polishing to the required surface finish;

[0059] c. Clean the sapphire with acetone and perform ultrasonic vibration;

[0060] d. Apply paste paste on the joint surface of two sapphire crystals, and use ethanol to dissolve Al 2 o 3 , SiO 2 The mixed powder with MgO is adjusted to paste slurry; Al 2 o 3 , SiO 2 The weight ratio with MgO is 7:2:1;

[0061] e. Butt assembly of two sapphire crystals;

[0062] f. Place it vertically in the fixture;

[0063] g. Apply pressure to the sapphire crystal in the vertical direction to complete the splicing and fixing of the two sapphire crystals;

[0064] h. Put the spliced sapph...

Embodiment 3

[0067] This embodiment discloses a kind of pasting slurry, and the pasting slurry is mixed with organic solvents such as ethanol and Al 2 o 3 , SiO 2 Composed of MgO, this paste paste can be used for splicing and fixing between sapphires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com