Preparation technology for nodular cast iron with TRIP (transformation-induced plasticity) effect

A nodular cast iron and preparation process technology, which is applied in the field of nodular cast iron preparation process with TRIP effect, can solve the problems of increasing production costs, etc., and achieve the effects of improving strength, simple equipment, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical aspects of the present invention will be further described below in conjunction with specific embodiments.

[0043] According to the chemical composition given in Table 1, after spheroidization and inoculation treatment, it is cast into billet, and heat treatment is carried out after machining to remove the surface.

[0044] Table 1 is the mass percent of each composition

[0045] Table 1

[0046] Numbering C Si mn S P Mg margin 1 3.42 2.5 0.18 0.016 0.041 0.047 Fe and unavoidable impurities

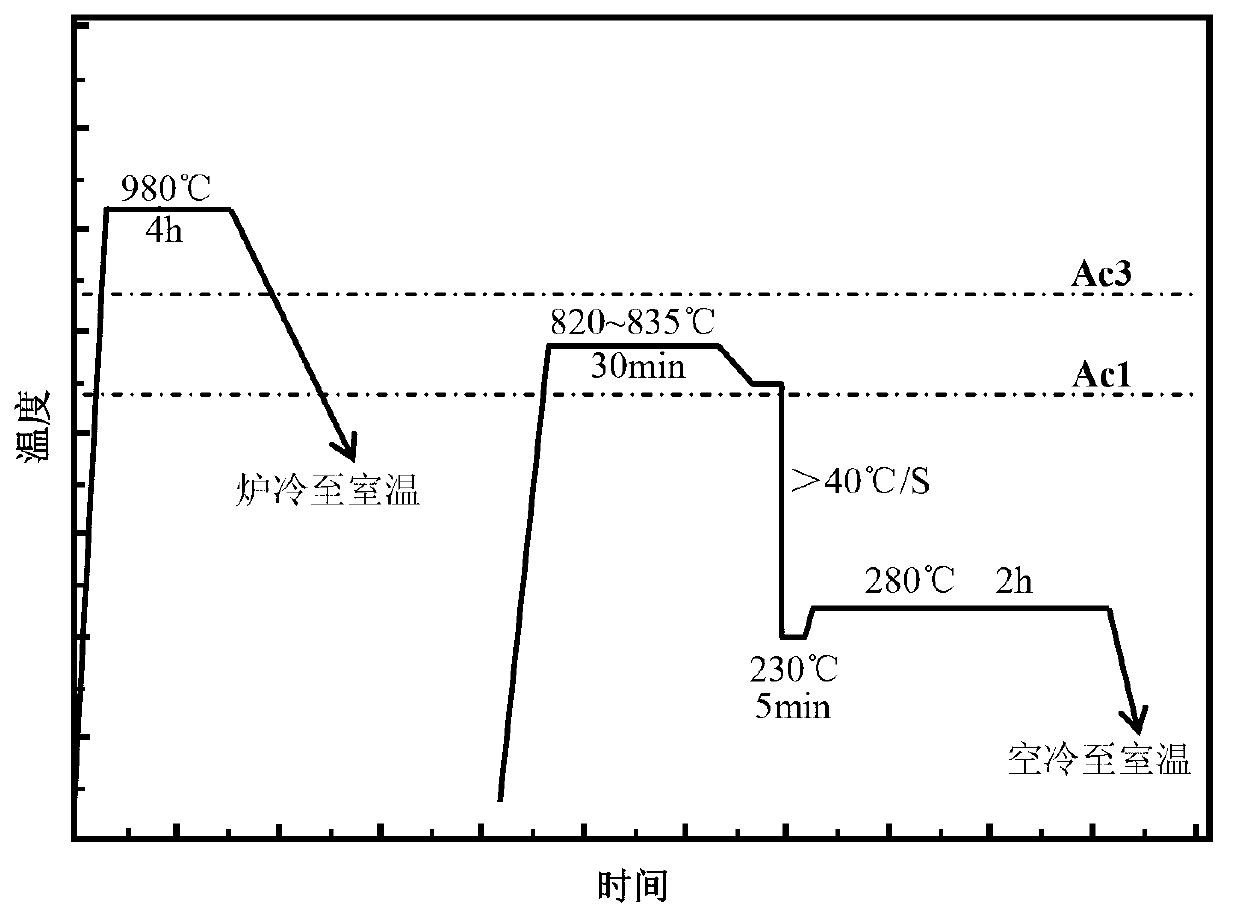

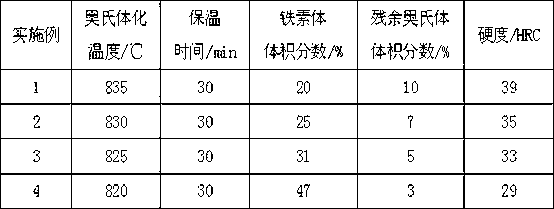

[0047] The cast ductile cast iron is kept at 980°C for four hours and then cooled with the furnace to obtain ferrite + graphite structure ductile iron. Then enter the heating furnace at 835°C for 30 minutes, slowly cool with the furnace to 805°C for 5 minutes, quickly cool down to 200°C, 210°C, 220°C, and 230°C at a cooling rate of 40°C for 5 minutes, and then heat at 5°C The heating rate of / S was raised to 280°C, 300°C, 350...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com