Device and method for producing large-size quartz glass by using composite induction-resistance melting induction smelting method

A quartz glass, large-scale technology, used in glass manufacturing equipment, glass production, glass molding, etc., can solve the problems of high melting temperature, high viscosity, complex quartz glass equipment, etc., to reduce internal stress and reduce bubbles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

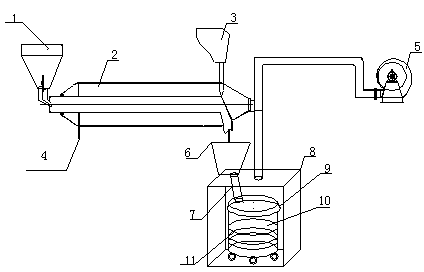

[0019] Describe in detail below in conjunction with accompanying drawing: As shown in the figure,

[0020] The equipment is as follows: the raw material warehouse 1 and the hydrogen storage tank 3 are respectively connected with the rotary cylinder 2, the hydrogen ignition hole 4 is installed on the rotary cylinder 2, the vacuum pump 5 is respectively connected with the rotary cylinder 2 and the melting chamber 8 through pipelines, and the melting chamber 8 is installed There is a smelting furnace body 10, and a smelting furnace cover 9 is installed on the upper part of the smelting furnace body 10. A resistance graphite heating body is installed on the smelting furnace cover 9, and a fixed pin is provided to ensure a tight connection with the smelting furnace body. An electromagnetic induction coil 11 is installed outside the smelting furnace body 10, and the outlet of the rotary cylinder 2 is connected to the feed pipe of the distribution bin 6, and the distribution bin 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com